Thin sheet for cigarette, preparation method thereof and cigarette

A technology of tobacco flakes and agricultural waste, which is applied in the field of cigarette processing, can solve the problems of limited harm reduction effect and unstable additive dosage, and achieve the effects of improving harm reduction effect, reducing release amount, and increasing burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

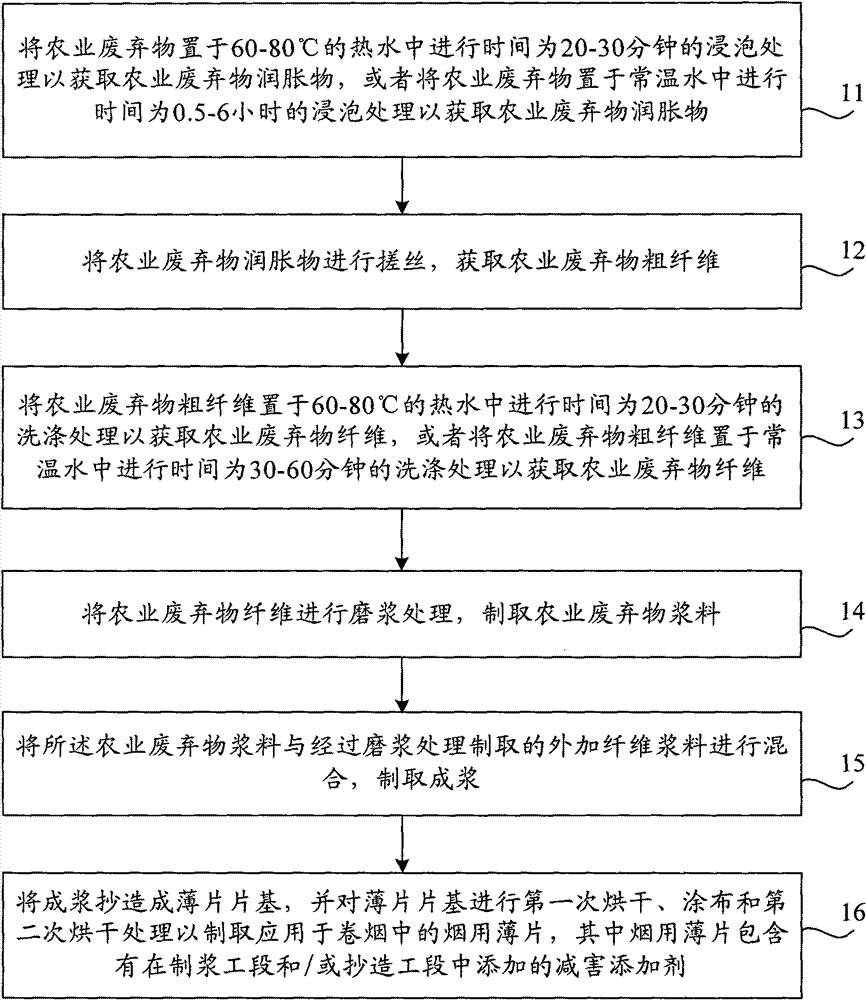

Method used

Image

Examples

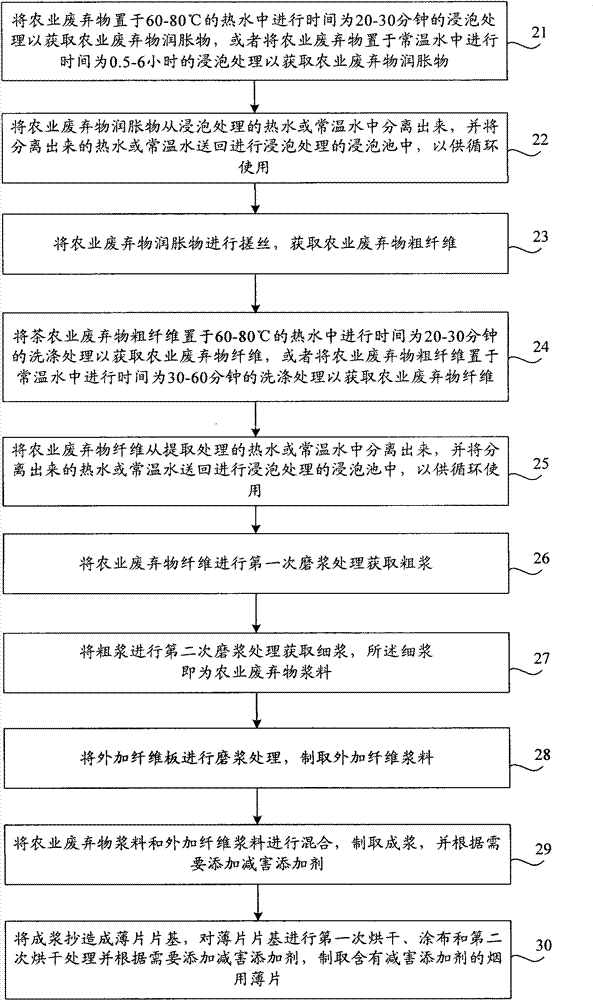

Embodiment 2

[0052] figure 2 The flow chart of the preparation method of the cigarette sheet provided by the second embodiment of the present invention, this embodiment can be realized based on the first embodiment, and this embodiment will focus on the differences, such as figure 2 Shown, the preparation method of the present embodiment comprises:

[0053] Step 21, soaking agricultural waste in hot water at 60-80°C for 20-30 minutes to obtain agricultural waste swelling, or placing agricultural waste in normal temperature water for 0.5-6 hours Soaking treatment to obtain agricultural waste swelling;

[0054] In this embodiment, the amount of hot water or normal temperature water used in the soaking treatment is preferably 10-15 times the weight of the agricultural waste, so as to fully soak the agricultural waste without wasting water resources.

[0055] Step 22, separating the swollen agricultural waste from the soaked hot water or normal temperature water, and sending the separated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com