Numerical-control double-roll veneer reeling machine with adjustable rounding diameter

A rolling and trigger technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not improving work efficiency, consuming a lot of manpower and material resources, increasing user production costs, etc., and achieving equipment operation accuracy High, reduce the cost of equipment use, increase the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

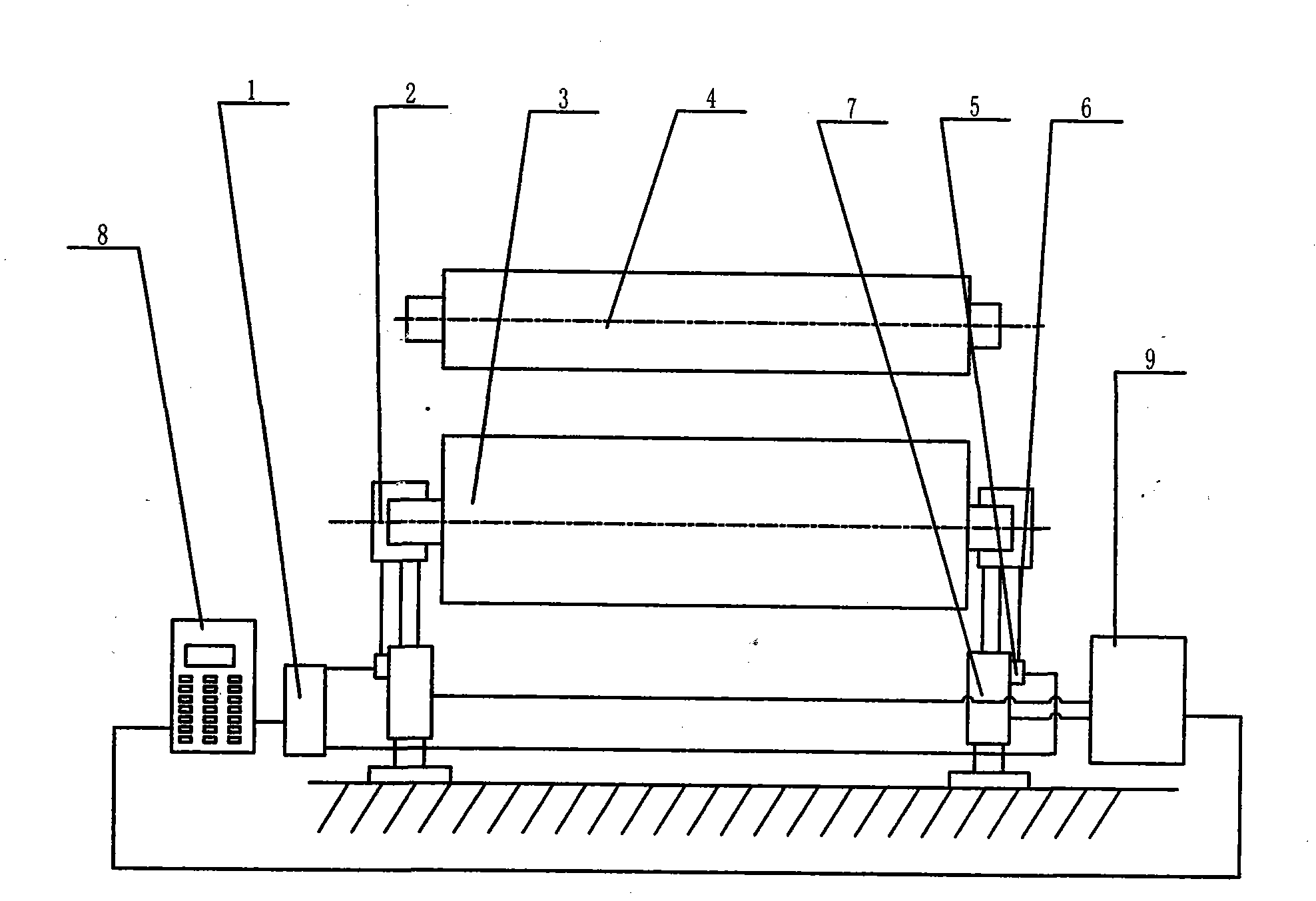

[0009] see figure 1 , the specific embodiment adopts the following technical scheme: it consists of a fixed upper roller 4, a lower rubber roller 3, a lower roller end bearing seat 2, a hydraulic cylinder 7, a sensor 5, a sensor contact device 6, a PLC controller 1, a numerical control device 8, The hydraulic control device 9 is composed of the fixed upper roller 4, and the lower rubber roller 3 is arranged on the two lower roller end bearing seats 2 under the fixed upper roller 4, and the two lower roller end bearing seats 2 are respectively fixed on two hydraulic pressure rollers. On the oil cylinder 7, sensors 5 are respectively arranged on the sides of the two hydraulic oil cylinders 7, and the sensor contact devices 6 of the sensors 5 are respectively fixedly connected to the two lower roller end bearing housings 2, and the signal output ends of the two sensors 5 are connected to the PLC The signal input terminal of the controller 1 is connected, the PLC controller 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com