Inverter welding machine major loop with PFC (Power Factor Correction) function

A technology of inverter welding machine and main circuit, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increased cost of electric welding machine products and lack of competitiveness of products, so as to reduce product failure rate, simple design, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

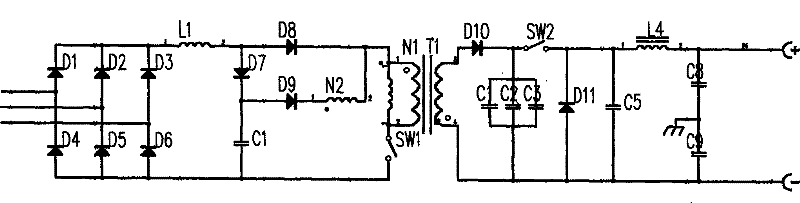

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0010] Such as figure 1 As shown, the main circuit of an inverter welding machine with PFC function, the three-phase power supply forms positive and negative poles after passing through the three-phase rectification circuit, and the positive and negative pole signals are transmitted to the primary two ends of the transformer T1 after passing through the PFC circuit; the transformer The positive pole of the secondary of T1 passes through the diode D10, the switch SW2, and the reactor L4 in sequence, and then outputs; there are three parallel capacitors C1, C2, and C3 between the diode D10 and the switch SW2, and the capacitors C1, C2, and C3 are connected in parallel to the transformer T1 The positive and negative ends of the secondary; a diode D11 and a capacitor C5 are provided between the switch SW2 and the reactor L4, and the diode D11 and the cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com