Colour steel sandwich panel with high combustibility grades and preparation method thereof

A combustion performance, sandwich panel technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of combustion performance degradation, etc., to improve the combustion level, reduce the degree of dripping, easy to control and The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

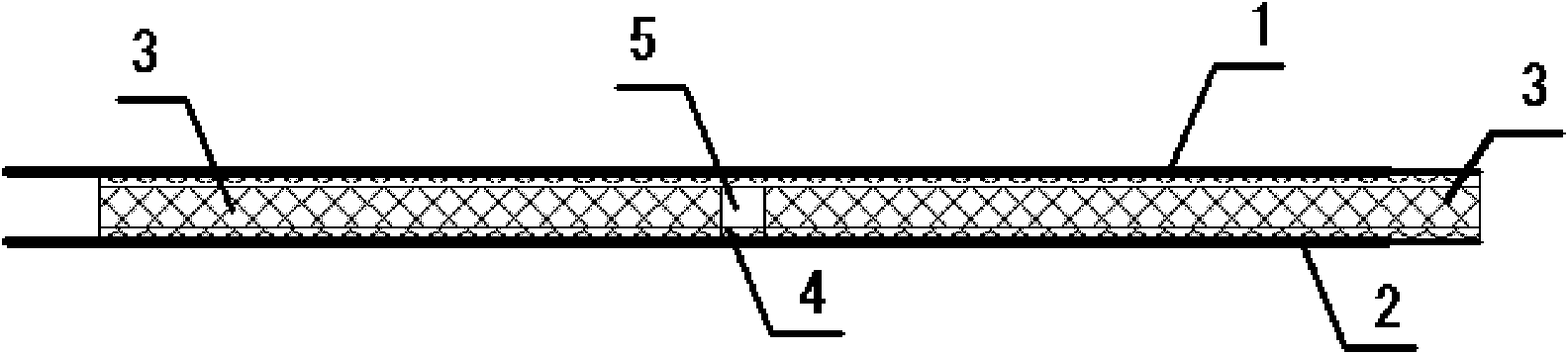

[0028] On the color steel sandwich panel production line, the color steel plate with a thickness of 0.3mm as the upper metal panel (1) and the color steel plate with a thickness of 0.3mm as the lower metal panel (2) are placed before the steel plate is grooved or the steel plate is grooved Finally, drip the adhesive on the side of the metal panel facing the light core material (3) through the glue dispensing device, and then apply the adhesive evenly through the glue leveling device to form an adhesive layer (4). The adhesive used is polyurethane adhesive (black and white glue ), consisting of white glue composed of combined polyether and black glue composed of isocyanate, the amount of black and white glue is 0.12kg / m 2 The upper and lower metal panels (1, 2) that have been coated with glue and the molded polystyrene (EPS) foam board as the lightweight core material (3) are compounded by a composite machine. The limiting oxygen index of the EPS foam board used is 34.5, and the...

Embodiment 2

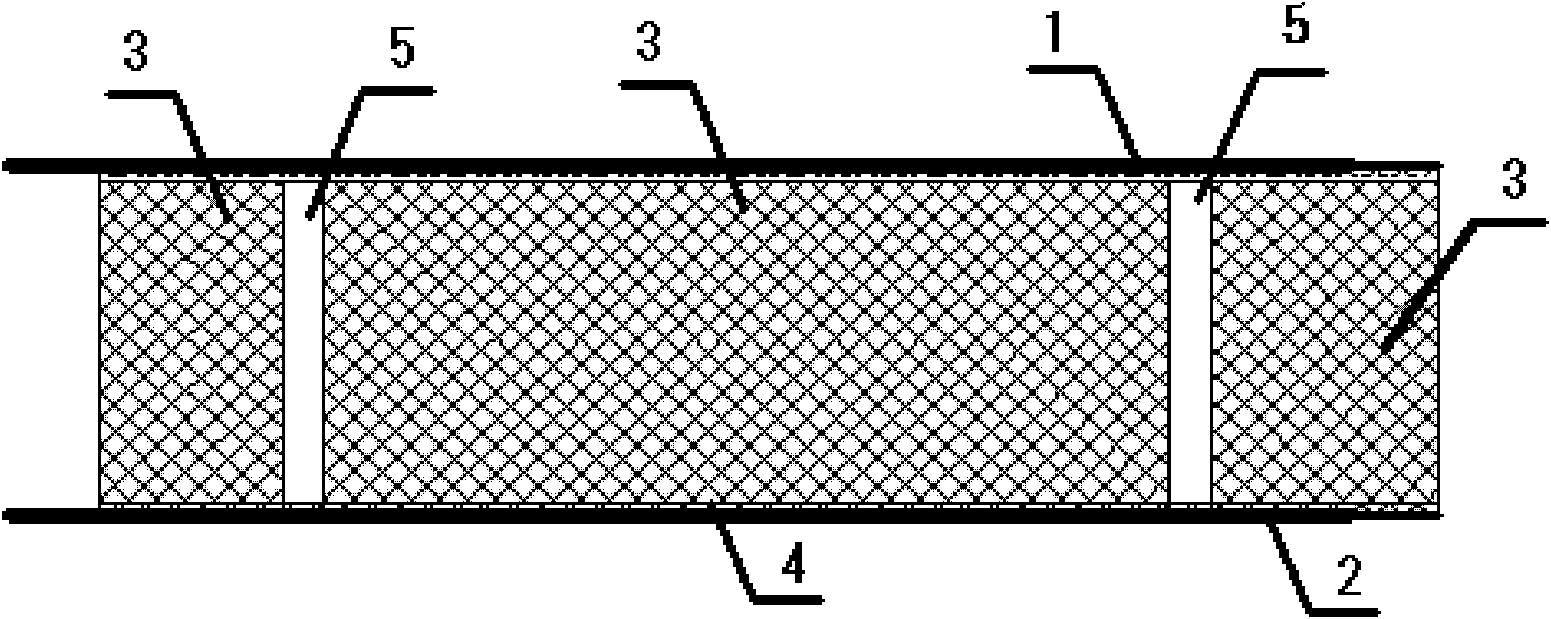

[0031] In the color steel sandwich panel production line, the galvanized color steel plate with a thickness of 0.3mm as the upper metal panel (1) and the galvanized color steel plate with a thickness of 0.3mm as the lower metal panel (2) are placed before the steel plate is grooved Or after the steel plate is grooved, use the glue dispensing device to drip the adhesive on the side of the metal panel facing the light core material (3), and then use the glue leveling device to evenly coat the adhesive to form an adhesive layer (4). The adhesive used is polyurethane Adhesive (black and white glue), composed of white glue composed of combined polyether and black glue composed of isocyanate, the amount of black and white glue is 0.11kg / m 2 The upper and lower metal panels (1, 2) that have been coated with glue and the EPS foam board as the lightweight core material (3) are compounded by a composite machine. The limiting oxygen index of the EPS foam board used is 32.5, and the thickn...

Embodiment 3

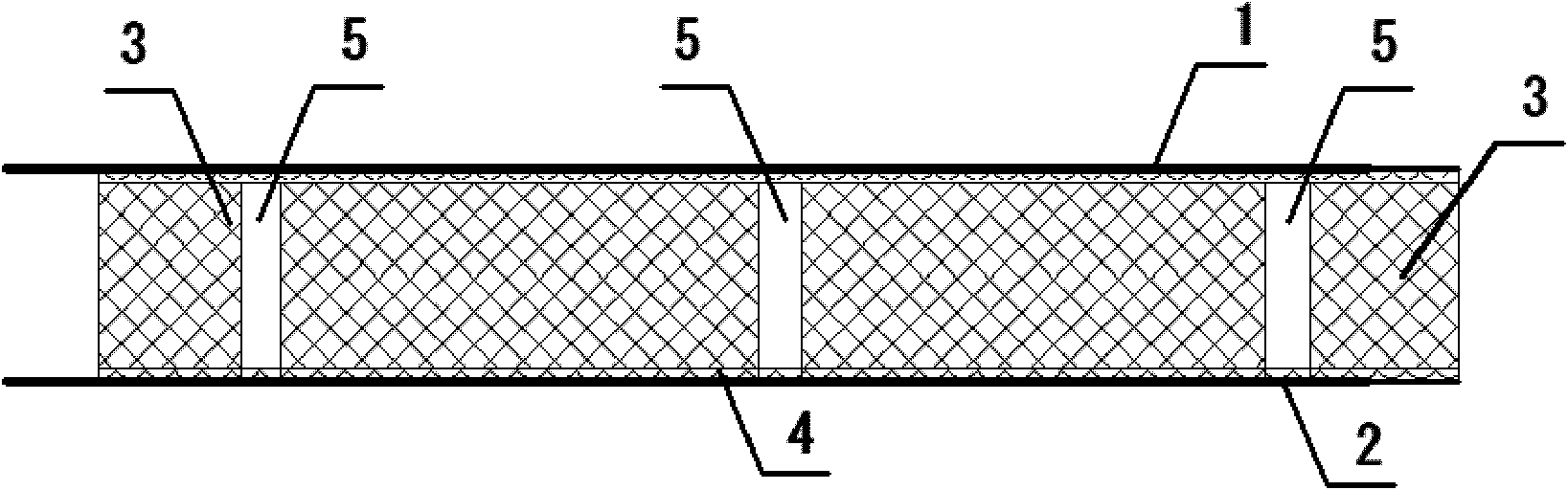

[0034] In the color steel sandwich panel production line, the galvanized color steel plate with a thickness of 0.5mm as the upper metal panel (1) and the galvanized color steel plate with a thickness of 0.5mm as the lower metal panel (2) are placed before the steel plate is grooved Or after the steel plate is grooved, use the glue dispensing device to drip the adhesive on the side of the metal panel facing the light core material (3), and then use the glue leveling device to evenly coat the adhesive to form an adhesive layer (4). The adhesive used is polyurethane Adhesive (black and white glue), composed of white glue composed of polyether and black glue composed of isocyanate, the amount of black and white glue is 0.13kg / m 2 ; The upper and lower metal panels (1, 2) coated with glue and the extruded polystyrene (XPS) foam board as the lightweight core material (3) are compounded by a composite machine. The XPS foam board used has a limiting oxygen index of 30.5, and the XPS fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com