Sewing machine needlework supplying device

A sewing machine and supplier technology, which is applied to sewing equipment, sewing machine components, and ferrule mechanisms for sewing machines, etc., can solve the problems of high cost, unsatisfactory user requirements, and complicated mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

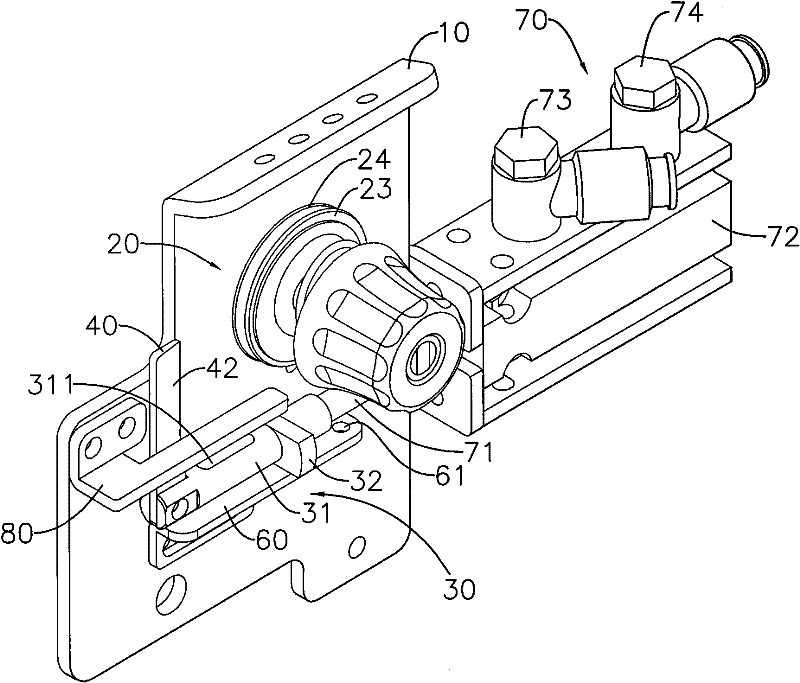

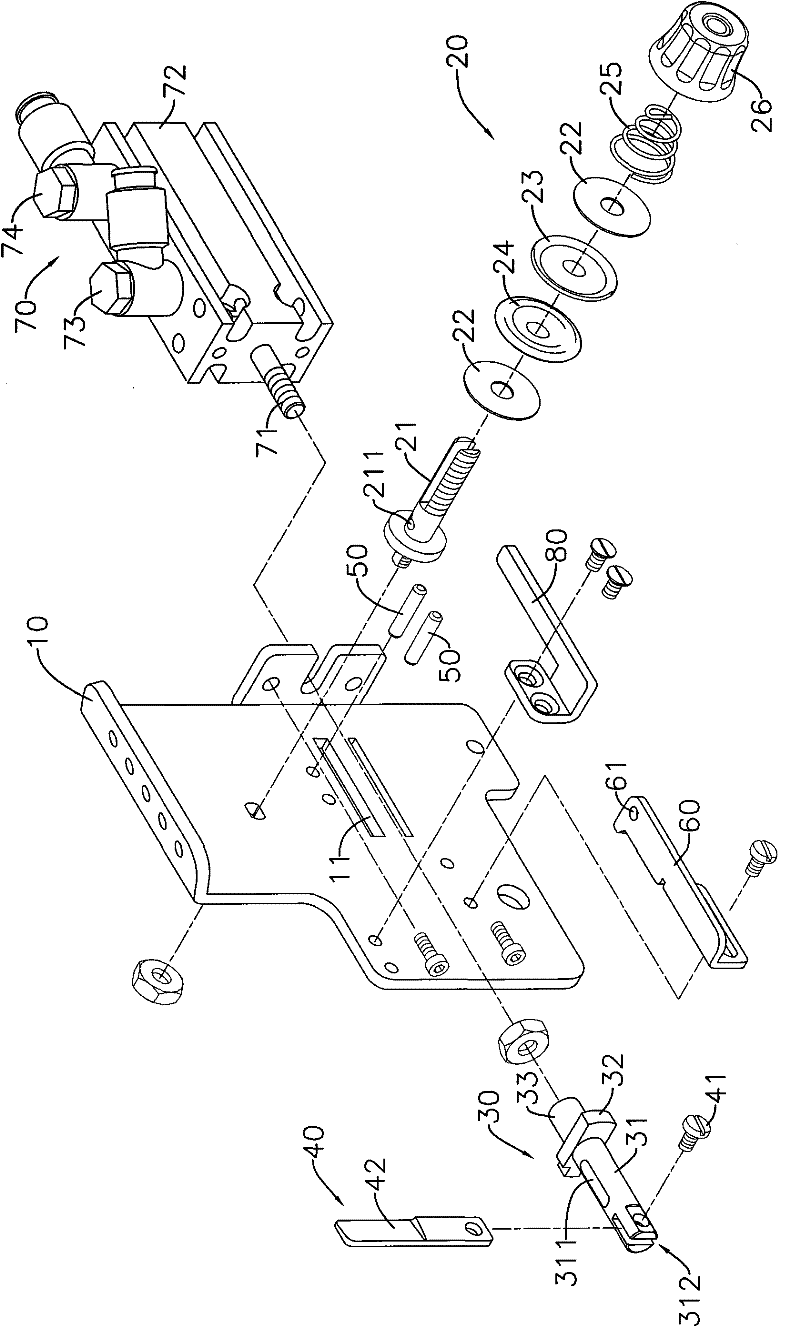

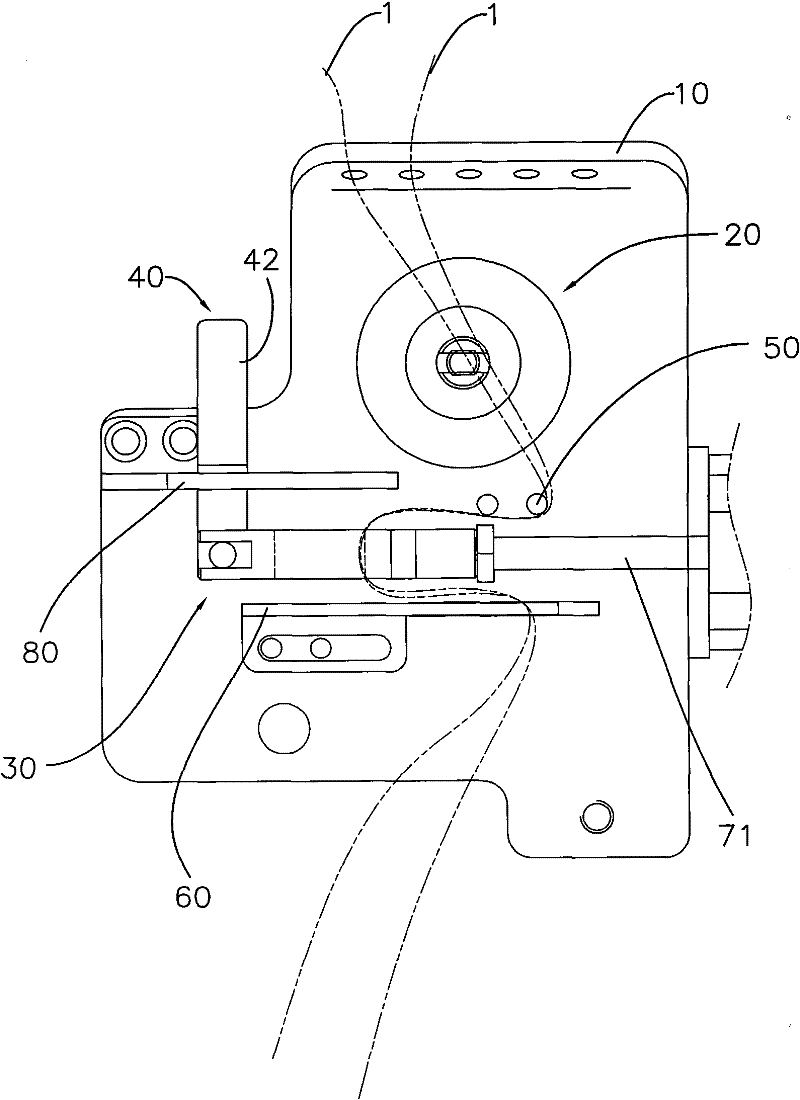

[0036] see Figure 1 to Figure 6 , the present invention is a needle thread feeder device of a sewing machine, the needle thread feeder device of the sewing machine comprises:

[0037] A base 10, at least one needle thread clamp set 20, a bobbin set 30, a dial 40, at least a fulcrum 50, a thread hanging plate 60, and a power set 70. The seat body 10 is for fixing on the sewing machine table; the needle thread clip group 20 is screwed on the seat body 10, and the needle thread clip group 20 is provided with a first needle thread clip sheet 23 and a second needle thread clip sheet 24 to For the elastic suture 1; the bobbin group 30 is provided with a bobbin 31, the front end of the bobbin 31 is for screw connection, and the middle section of the bobbin 31 is a hollow body 311 for the thread 1 to pass through, and The rear end of the bobbin 31 is a clip body 312 for clamping; the lower part of the dial 40 is inserted on the rear end of the bobbin 31 of the bobbin group 30, screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com