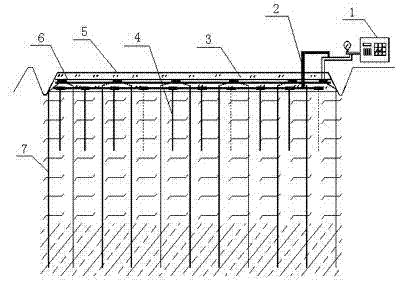

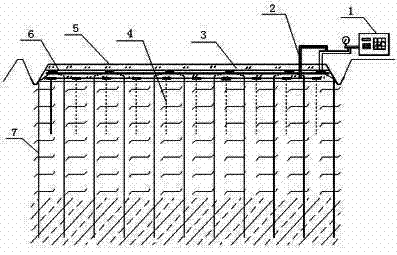

Long-short plastic drainage plates-combined secondary vacuum preloading foundation processing method

A plastic drainage board and secondary vacuum technology, which is applied in the field of foundation treatment and soft soil foundation, can solve the problems of increased construction cost, long treatment time, and unsatisfactory engineering practical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Shallow short drainage board pretreatment

[0013] ⑴. The field is leveled by machinery, and the flatness reaches 5‰.

[0014] (2) Lay a layer of woven cloth; if dealing with ultra-soft ground, arrange 200-300g geotextiles, and use plastic foam wrapped in filter membranes as artificial enclosures.

[0015] ⑶. Carry out the construction of the longitudinal drainage body, calculate and determine the spacing and depth of the plastic drainage boards and the specifications and models of the drainage boards used according to the geological conditions. The exposed length of the plastic drainage board is determined according to the spacing, generally 40-60cm, and the head of the board and the wrapped filter cloth are required to be complete and even, and there must be no mud ingress.

[0016] ⑷. For the setting of the horizontal drainage system, the thickness is 4.0±0.2mm, the width is 100±2mm, the vertical water flow is ≥60cm3 / s, the permeability is ≥5×10-3cm / s, and the equiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com