Novel vertical energy-saving oil pumping unit

A pumping unit and vertical technology, applied in the field of new vertical energy-saving pumping units, can solve the problems of poor energy-saving effect of vertical pumping units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

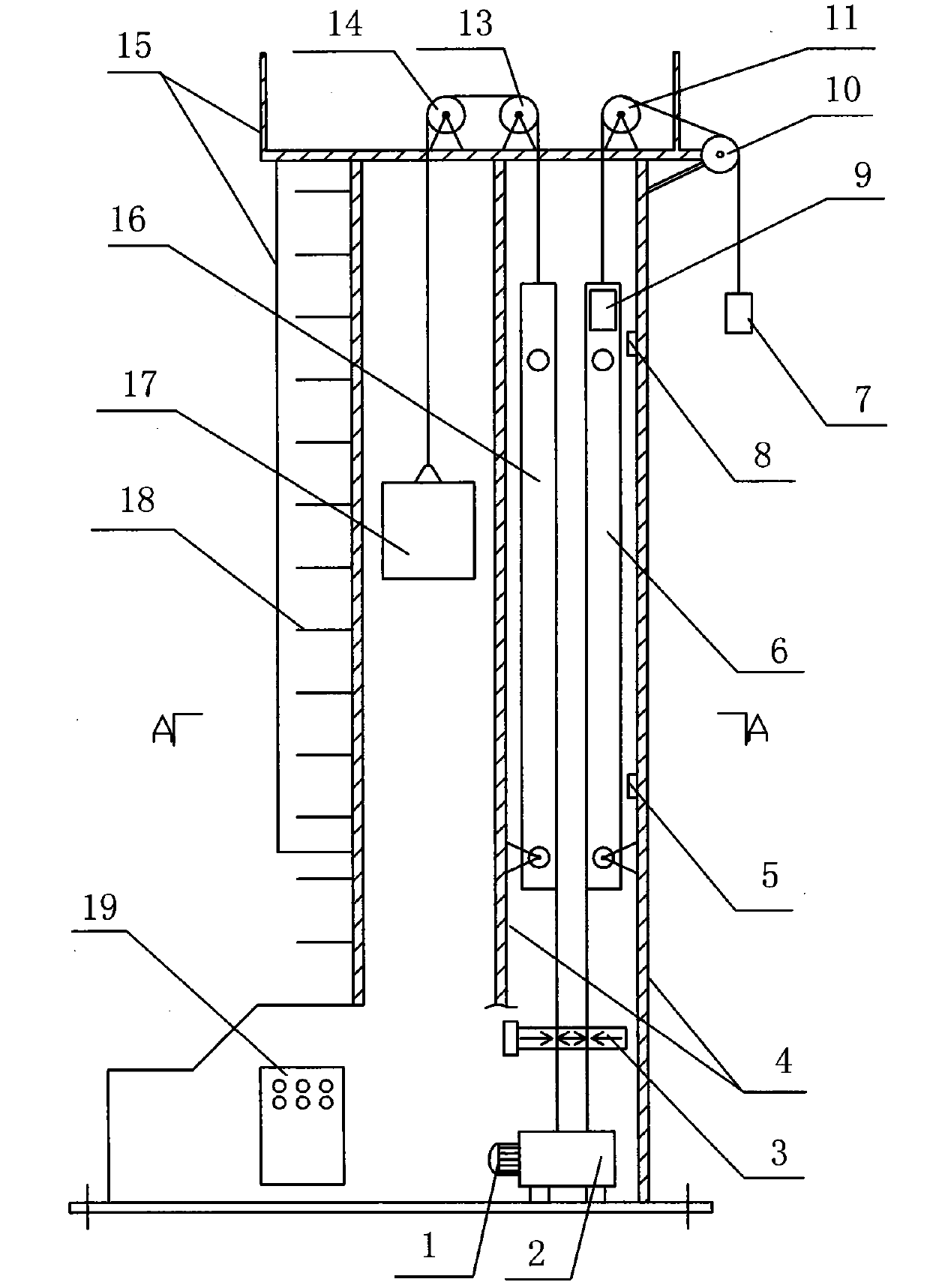

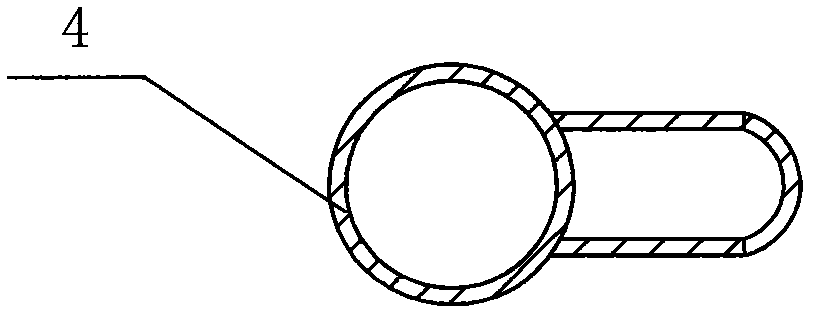

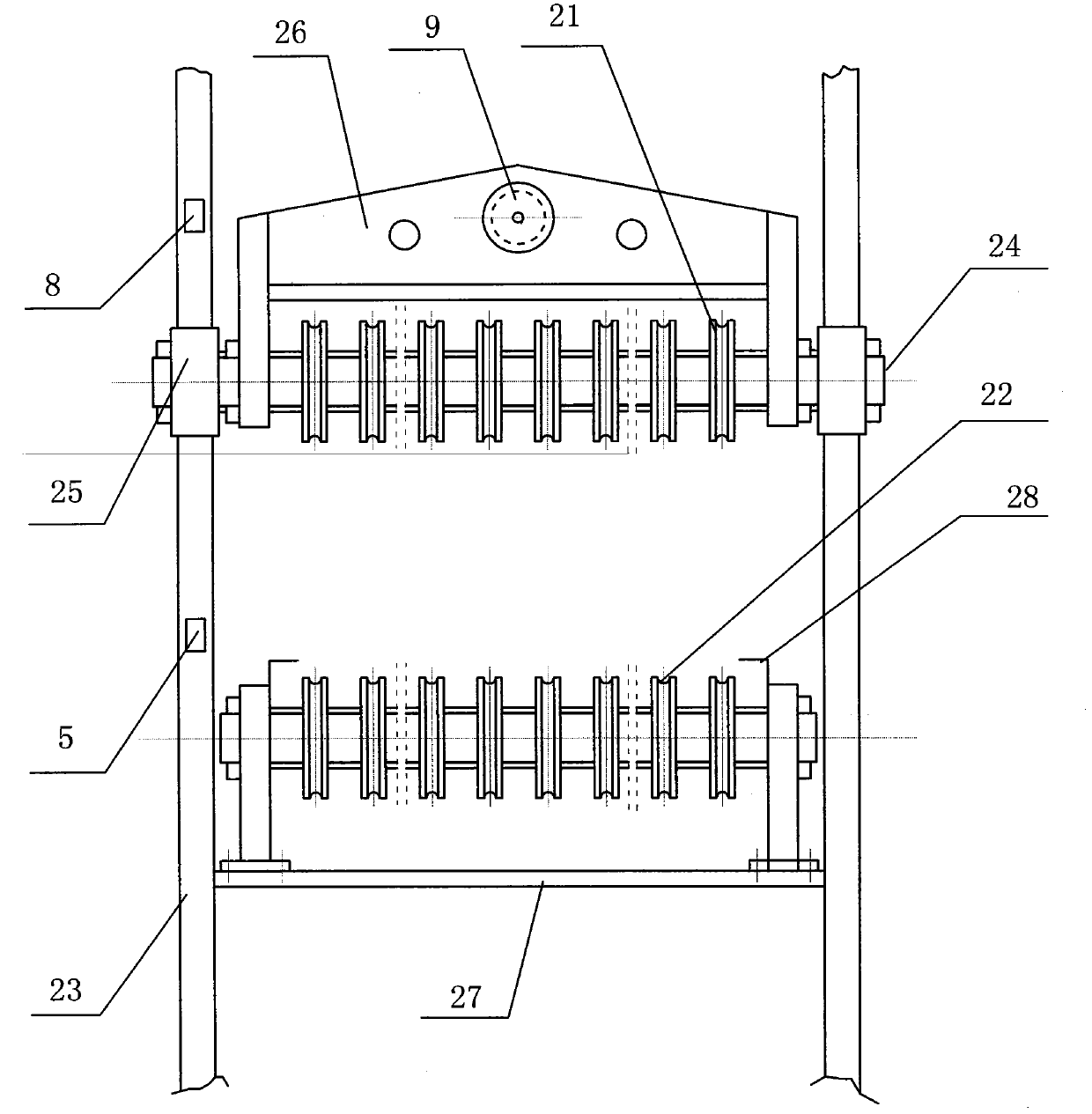

[0020] figure 1 , figure 2 A structural schematic diagram of the first embodiment of the present invention is provided, as shown in the figure, the bracket 4 of this new vertical energy-saving pumping unit is a combination of a cylindrical metal hollow cylinder and a flat metal hollow cylinder , the upper end of the bracket 4 is a platform, the balance weight 17 can move up and down in the cylindrical metal hollow cylinder, two gravity distributors (6, 16) are installed in the flat metal hollow cylinder, the motor 1 and the motor Drag device 2 is installed on the base of support 4, and electric control box 19 is also installed on the base of support 4, guardrail 15 and climbing ladder 18 are installed on support 4, for the convenience of maintenance, also be provided with manhole on support; Balance counterweight 17 It is connected to the gravity distributor 16 through the lifting system; the sucker rod system is connected to another gravity distributor 6 through the self-ba...

Embodiment 2

[0027] Compared with Embodiment 1, this embodiment differs in that the two gravity distributors (6, 16) are respectively connected to the motor drive device 2 through respective flat flexible belts, because the flat flexible belts will be laminated one by one. Layers are evenly wound on the cylinder 36 of the motor drive device, so the power centralizing device 3 is also omitted in the present embodiment, specifically as Figure 7 Shown, others are identical with embodiment 1.

Embodiment 3

[0029] Compared with Embodiment 1, the difference of this embodiment is that the balance counterweight anti-falling system is added. The steel wire rope will break due to fatigue due to long-time work. Once the steel wire rope breaks, the balance weight 17 will fall down, causing danger. In order to prevent this phenomenon from happening, a balance counterweight anti-falling system is added. The balance counterweight anti-falling system is composed of an anti-off steel wire rope and a rotating wheel. The rotating wheel is installed on the base of the bracket 4. There is a gravity spring on the rotating wheel. One end of the anti-off steel wire rope is fixed on the gravity distributor 16 connected to the lifting system. On the movable pulley block, the other end goes around the rotating wheel of the base downwards, and then upwards is connected to the movable pulley block of the gravity distributor 6 connected with the self-balancing system of the rope hanger. 6,16) two moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com