Rankine-cycle-based vortex disc engine system

An engine system, Rankine cycle technology, applied in the direction of machine/engine, arc meshing engine, mechanical equipment, etc., can solve the problems of high design and production cost, complex engine structure, sufficiency limitation, etc., to achieve reasonable structural design, The effect of high promotion and utilization value and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

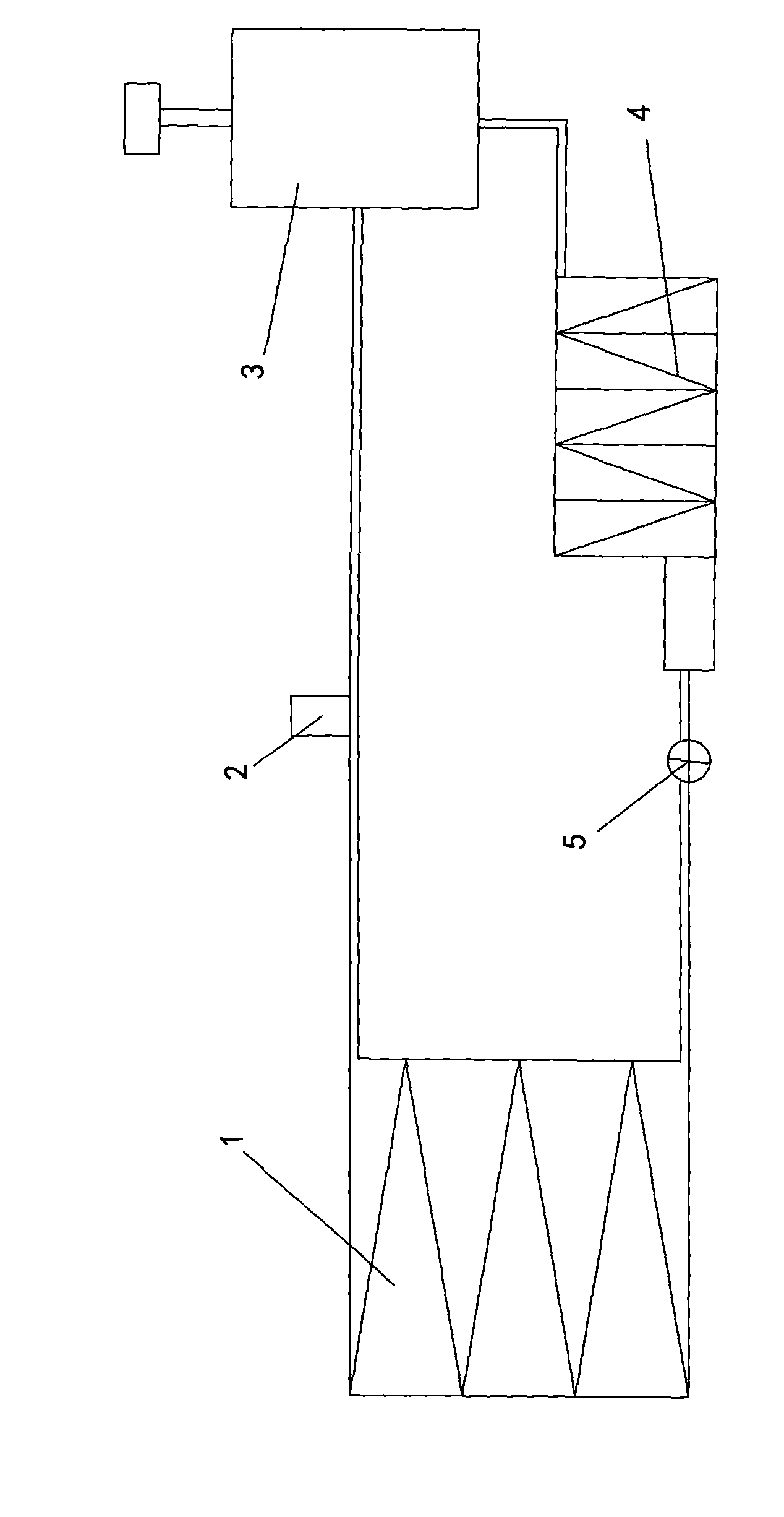

[0019] Such as Figure 1~4 As shown, the scroll engine system of the present invention is based on the Rankine cycle as the basic principle. The closed circulation loop is formed, and the circulation loop is filled with working fluid. The boiling point of the working medium is preferably in the low temperature region. The working fluid is filled in the vacuum state of the entire closed circulation loop, which can greatly reduce the working fluid. The boiling point accelerates the vaporization of the liquid working medium, which is conducive to the formation of high-pressure steam, and is also conducive to the condensation of the gaseous working medium.

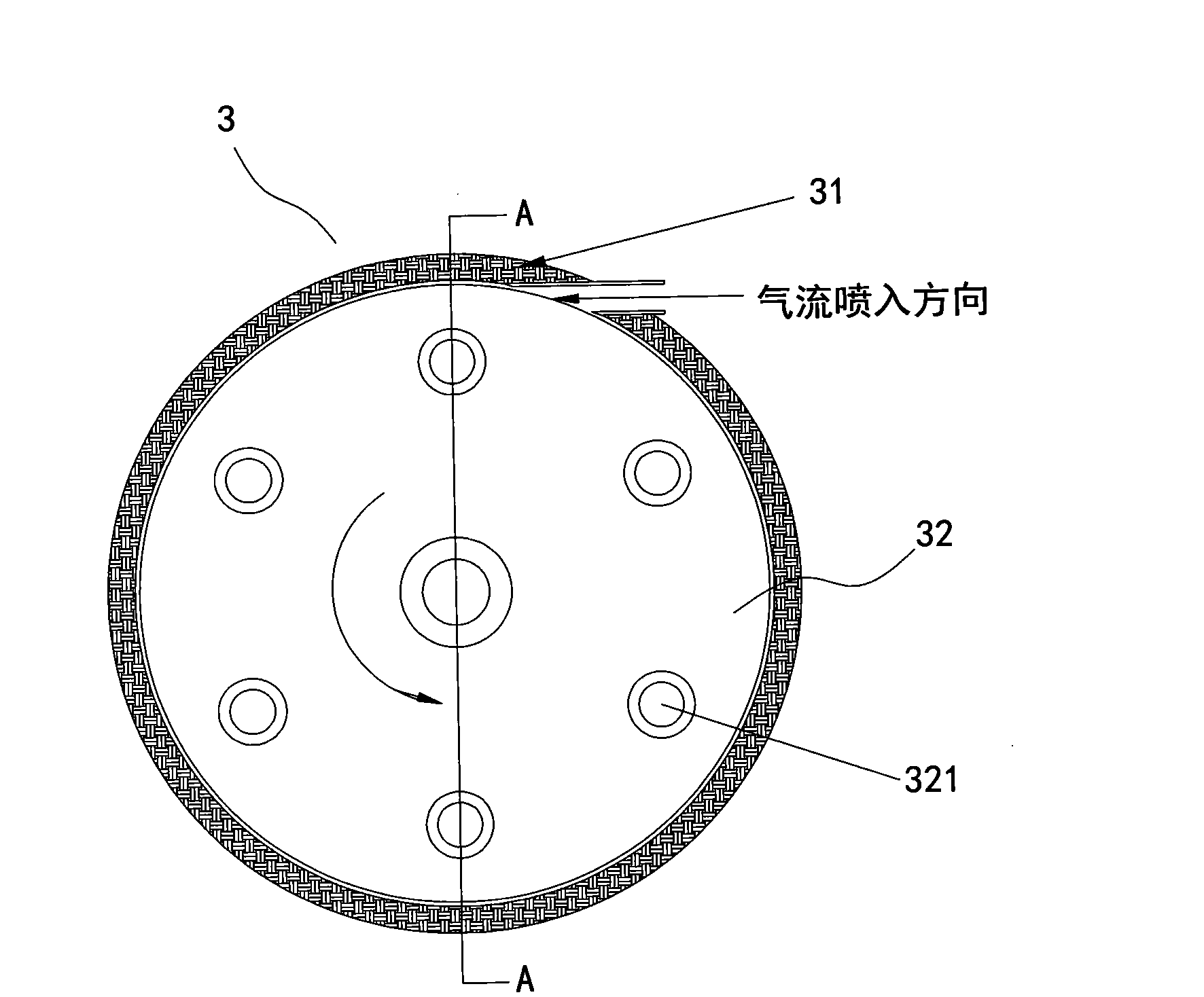

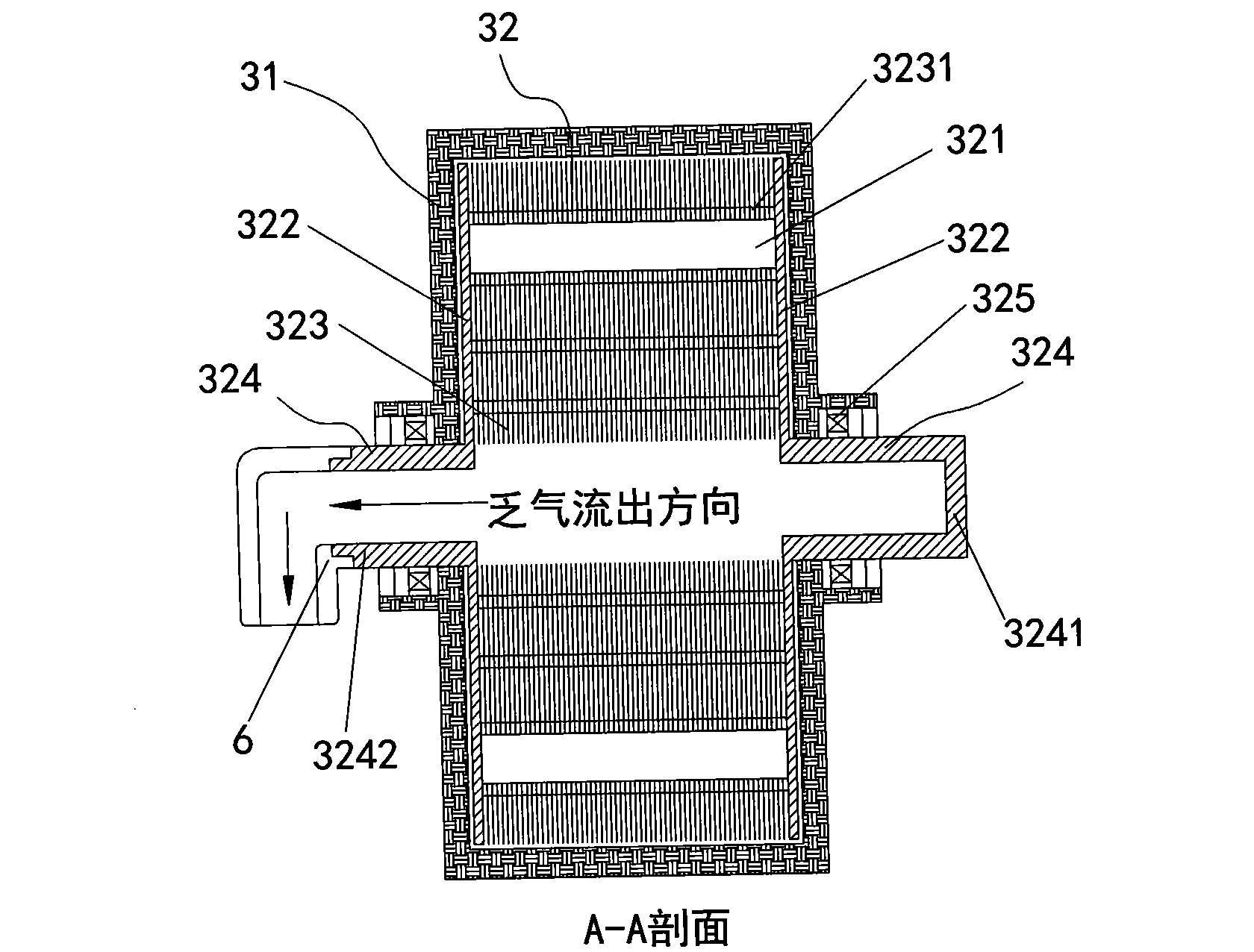

[0020] Specifically, in the engine system of the present invention, the scroll engine 3 includes a casing 31 having an air inlet 310 and a scroll plate set 32 installed in the casing 31 and driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com