Structured light-based high-speed detection system and method for railway fastener

A railway fastener and detection system technology, applied in the field of devices in the field of optical detection technology, can solve the problems of poor versatility and slow recognition speed, and achieve the effect of fast speed, strong versatility and less information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

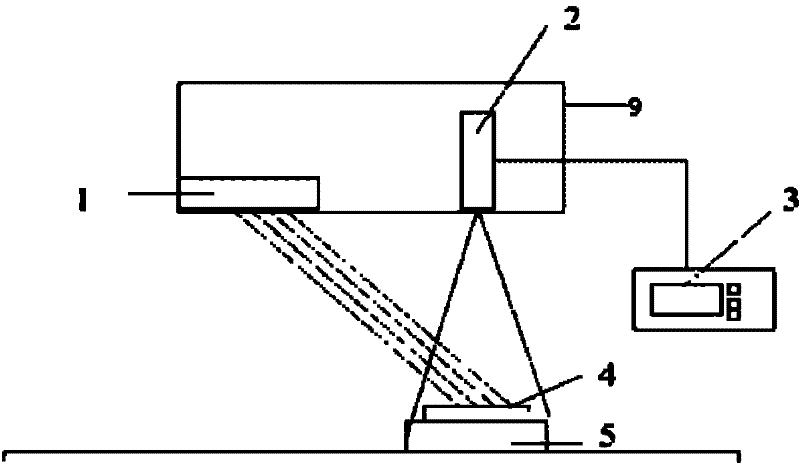

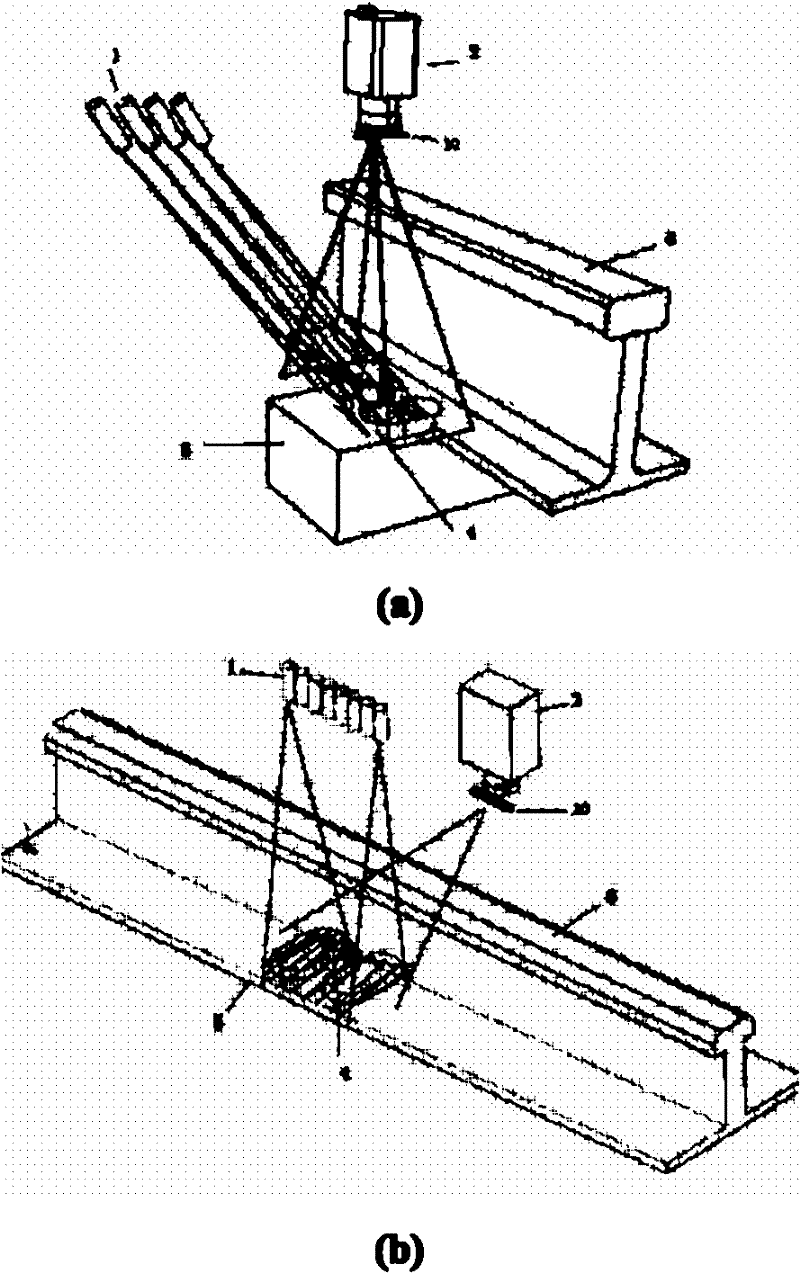

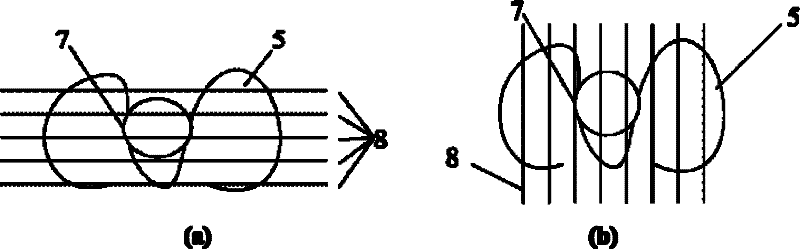

[0042] Such as figure 1 with figure 2 As shown, this embodiment includes: a laser light source 1, a high-speed camera 2 and a processing system 3, wherein: the laser light source 1 and the high-speed camera 2 are respectively arranged above the area where the fastener to be tested 4 is located, and respectively emit a group of structured light The high-speed camera 2 shoots the image of the fastener area. The high-speed camera 2 is connected to the processing system 3 and transmits the image. The processing system 3 performs image processing and judgment to obtain the detection result.

[0043] The laser light source 1 is specifically arranged in the fairing 9 at the bottom of the compartment above the fastener. The laser light source 1 is composed of a plurality of independent semiconductor laser line light sources 1 arranged in a row, and the laser wavelength is 628nm.

[0044] The semiconductor laser line laser light source 1 vertically irradiates the area where the faste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com