Testing module for adapter element

A technology for testing modules and components, applied in the field of test modules for switching components, can solve the problems of lengthening the testing time of switching components, affecting production costs and product quality, and error testing, so as to improve production costs and product quality, simplifying Human-computer interaction test work, the effect of reducing the probability of test failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After those skilled in the art understand the embodiments of the present invention, they can be changed and modified by the techniques taught in the present invention without departing from the present invention. spirit and scope.

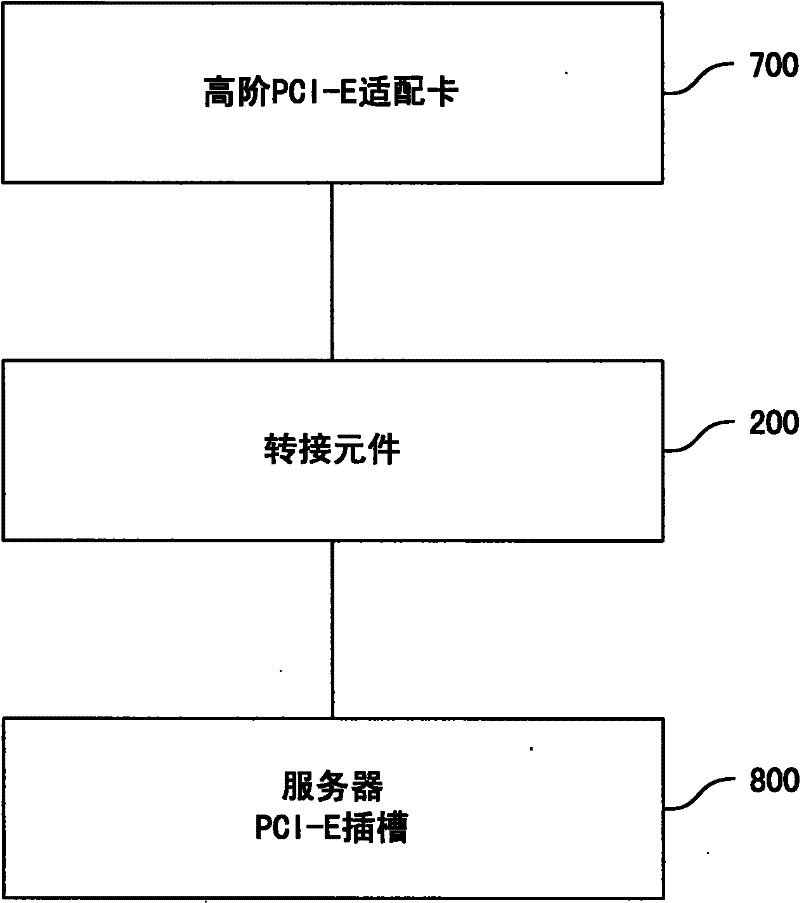

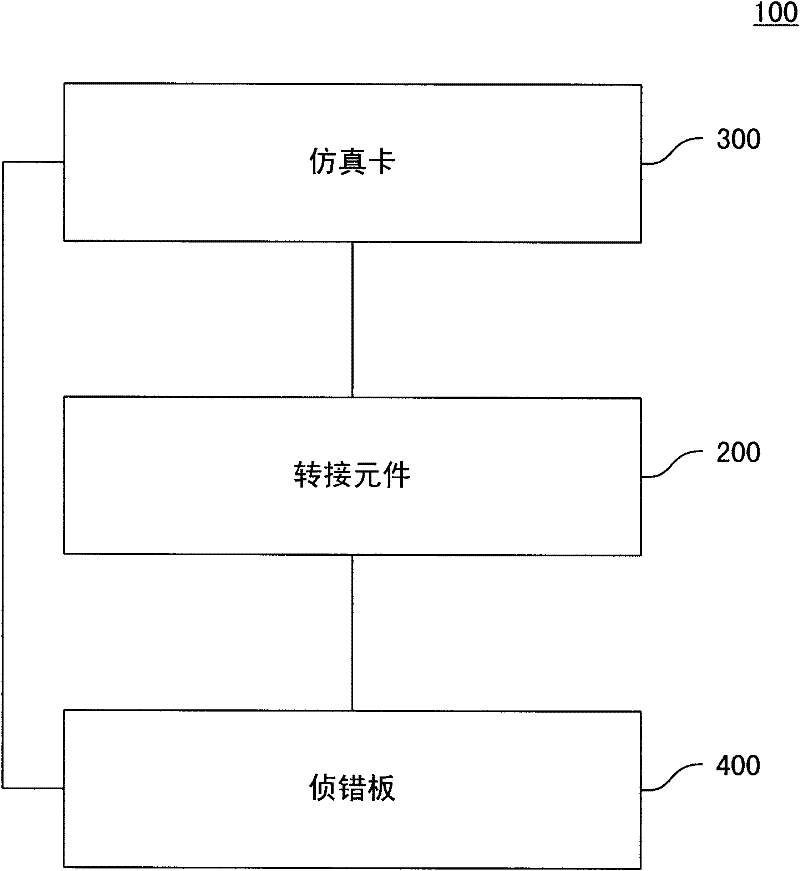

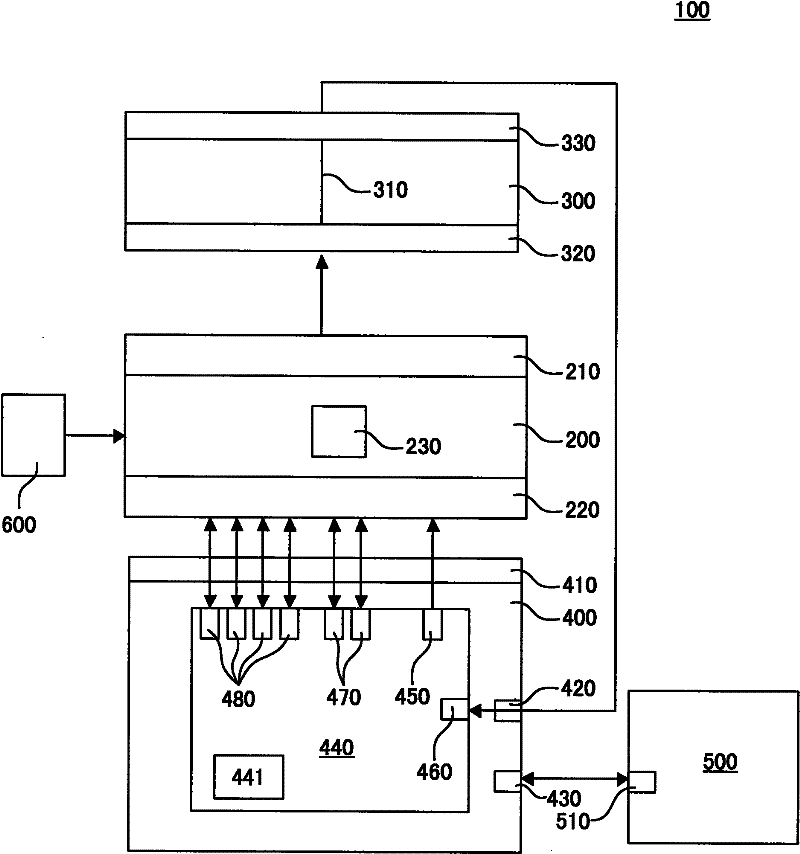

[0040] Please refer to figure 2 as shown, figure 2 A schematic block diagram showing a test module of the adapter element of the present invention. The present invention discloses a test module for an adapter component. The test module 100 at least includes an adapter element 200 to be tested, an emulation card 300 and a debug board 400 . The dummy card 300 is electrically connected to the adapter element 200 . The debug board 400 is electrically connected to the adapter element 200 and the emulation card 300 respectively, and forms a loop with the adapter element 200 to be tested and the emulation card 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com