Full-automatic double-injection molding machine

A double-injection molding machine, fully automatic technology, applied in the direction of household components, household appliances, and other household appliances, can solve the problems of high work intensity, low labor efficiency, poor environment, etc., to reduce operators, improve production efficiency, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing of description:

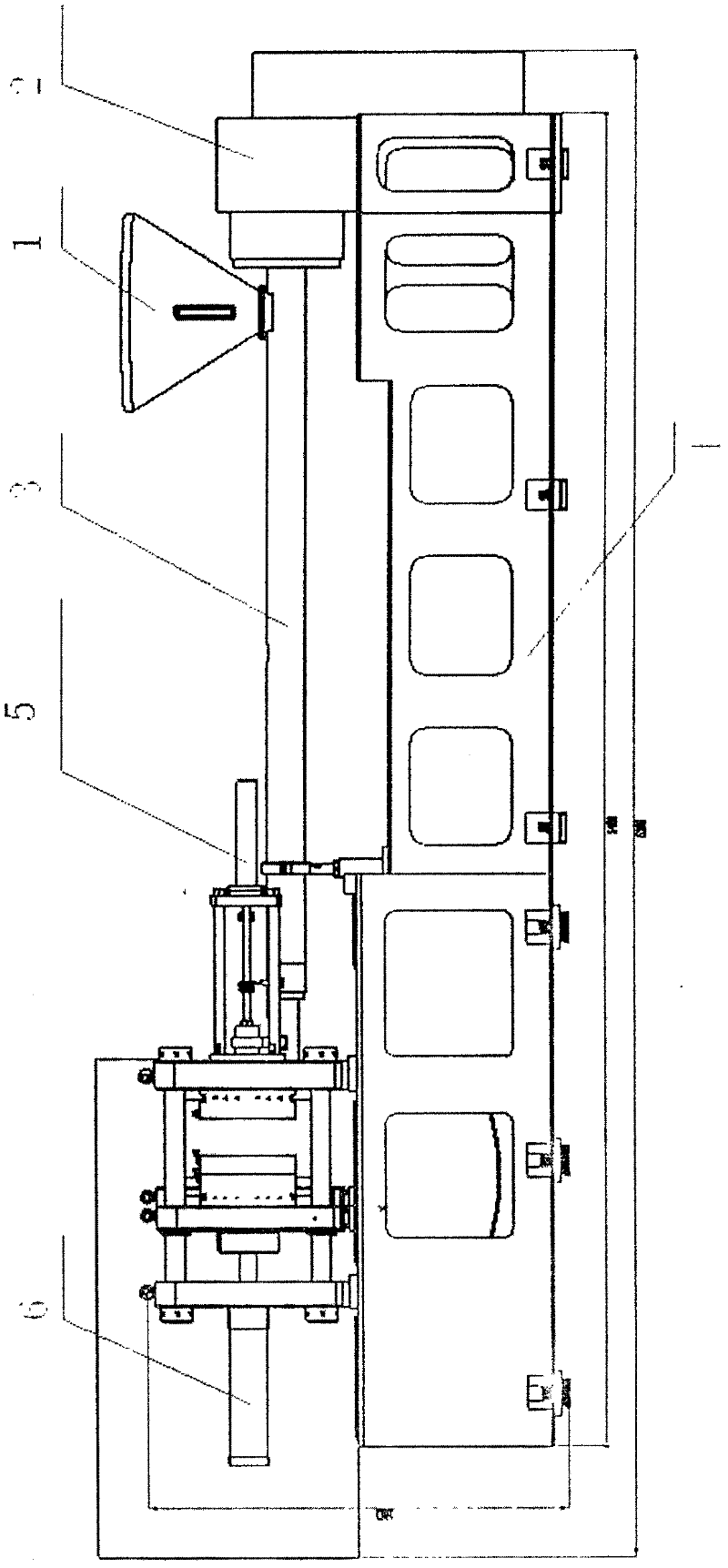

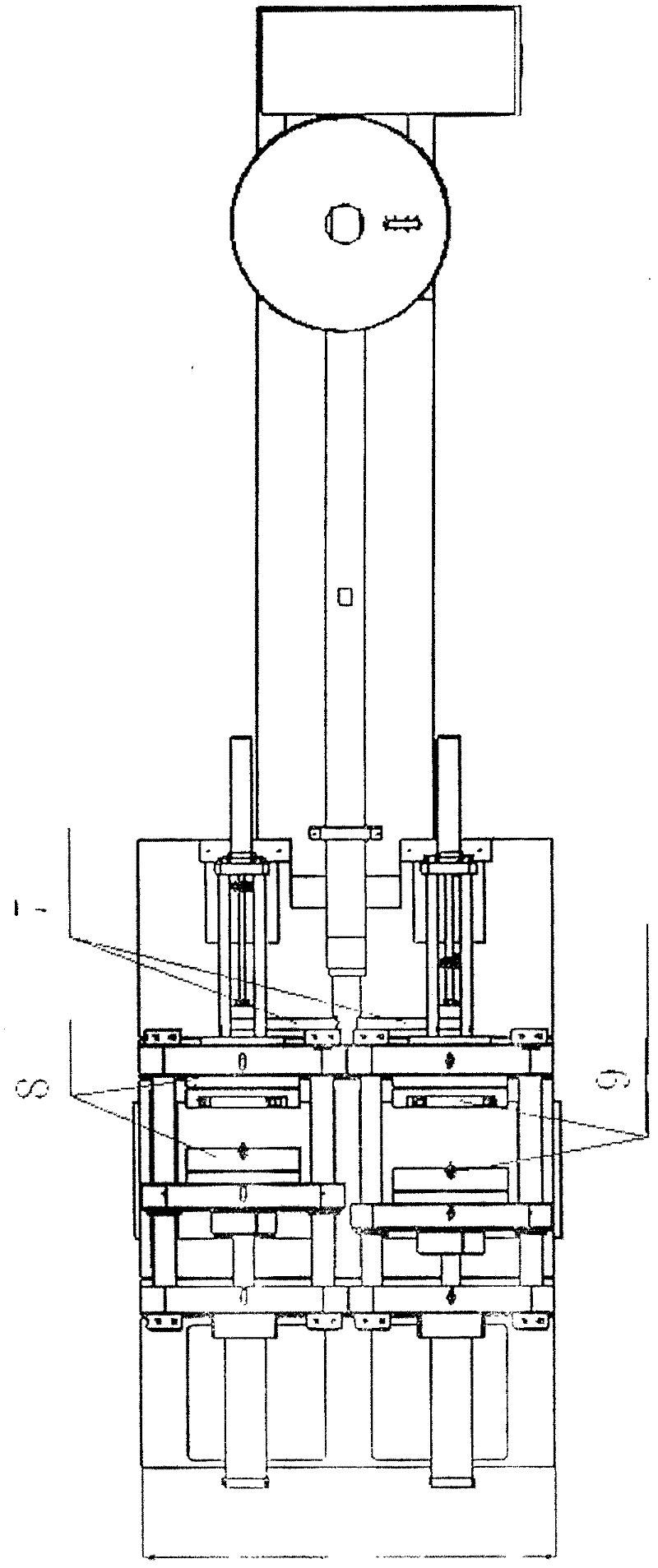

[0015] see figure 1 , figure 2 As shown, a fully automatic microcomputer double injection molding control system, loading hopper 1, reducer 2, extrusion screw 3 and frame 4, the injection last billet of the charging hopper passes through the reducer and extrusion screw, and the molten raw material is pushed Into the hydraulic mold clamping device 6; also provided with the feed and ejection mechanism 5 that will be respectively distributed to the two injection molds 7 for the melted raw materials;

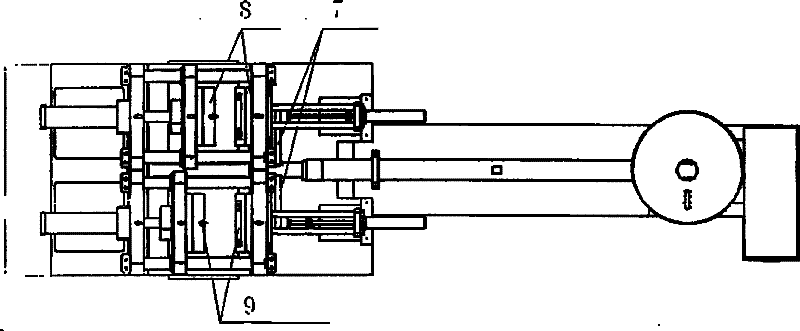

[0016] The double-injection mold diversion device 8 is a variable water channel circulation structure that can be used in combination with the left and right molds;

[0017] The laser detection control mechanism 9 is arranged on the splitting device 8 of the double injection mold.

[0018] The distribution device 8 distributes the melted raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com