Metal honeycomb energy-gathering air-saving burner for gas stove

A metal honeycomb, gas stove technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of easy local protrusion (protrusion) or subsidence, risk of tempering, tempering and deflagration, etc. Safety performance, reduction of solder joints, effect of reducing internal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

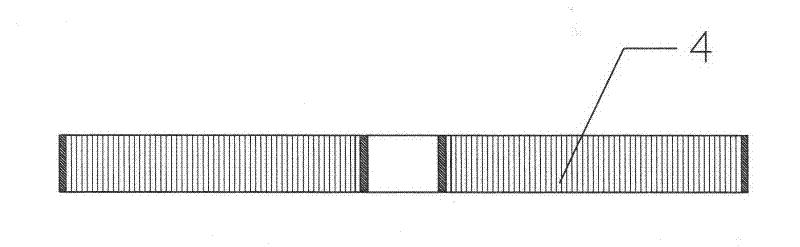

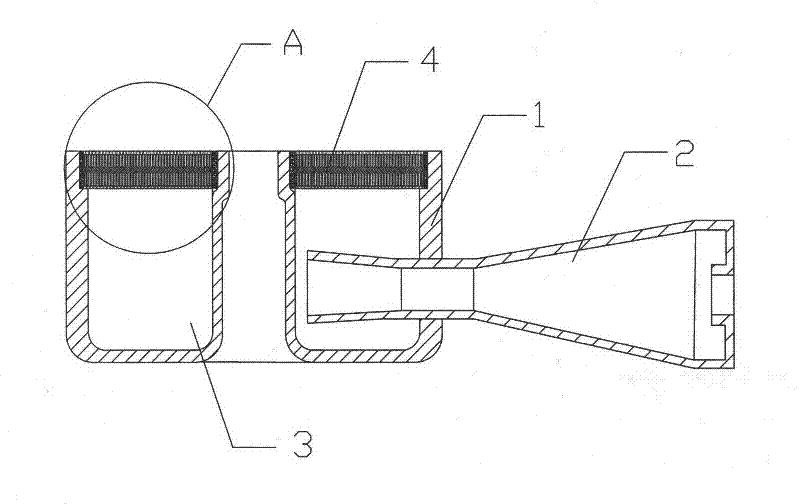

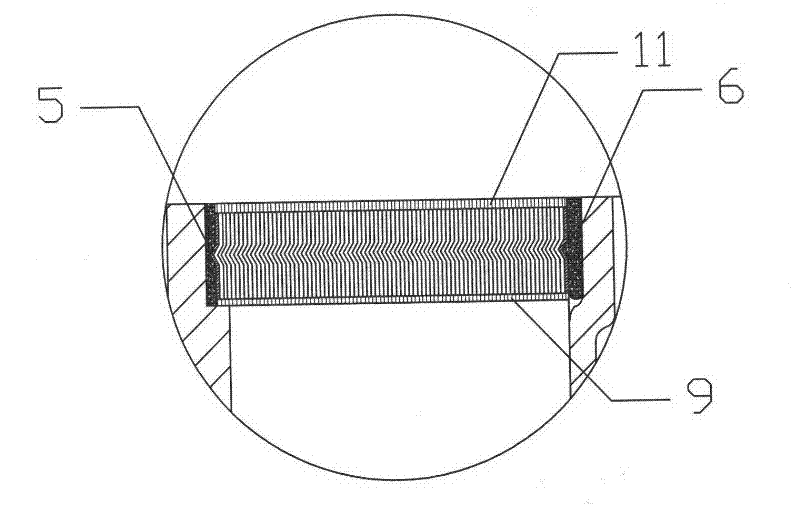

[0037] Embodiment one: if Figure 2-Figure 6 As shown, the metal honeycomb body energy-saving gas-saving burner for gas stoves in this embodiment is mainly composed of a burner body 1, an injection pipe 2, and a gas mixing chamber 3. The inner cavity on the upper part of the gas mixing chamber 3 There is a metal honeycomb body infrared burning plate 4 which is formed by interlacing or coiling or intertwining elongated flat sheets 40 and elongated corrugated sheets 41, and the inner and outer rings of the metal honeycomb body infrared burning plate 4 are provided with fixing rings 5, In this way, the connection between the elongated flat sheet 40 and the elongated corrugated sheet 41 can prevent local protrusions or downward movement even without welding. The elongated flat sheet 40 and the elongated corrugated sheet 41 have a stamped ">"-shaped structure in the middle of the height direction, and the shape of the surface of the fixed ring 5 in contact with the metal honeycomb ...

Embodiment 2

[0038] Embodiment two: if Figure 9 As shown, the metal honeycomb infrared combustion board 4 used in the metal honeycomb energy-saving gas-saving burner for gas stoves in this embodiment has a fold in the middle of the elongated flat sheet 40 and elongated corrugated sheet 41 in the height direction. The bent structure is a "]"-shaped structure,

Embodiment 3

[0039] Embodiment three: as Figure 10 , Figure 11 As shown, the metal honeycomb infrared combustion board 4 used in the metal honeycomb energy-saving gas-saving burner for gas stoves in this embodiment has a bending structure in the height direction of the elongated flat sheet 40 and the elongated corrugated sheet 41. It is a ">" shape structure. In order to improve the mechanical strength of the metal honeycomb infrared combustion panel 4 in working condition, a high temperature and oxidation resistant wire mesh 9 can be welded or added at its bottom (see Figure 12 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com