Motorcycle vehicle frame fixing device

A technology for fixing devices and motorcycles, which is applied to measuring devices, instruments, and components of measuring instruments. It can solve the problems of low measurement efficiency, high labor intensity of operators, and affecting the speed of measurement, so as to reduce labor intensity and avoid repeated measurement. , Improve the effect of measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

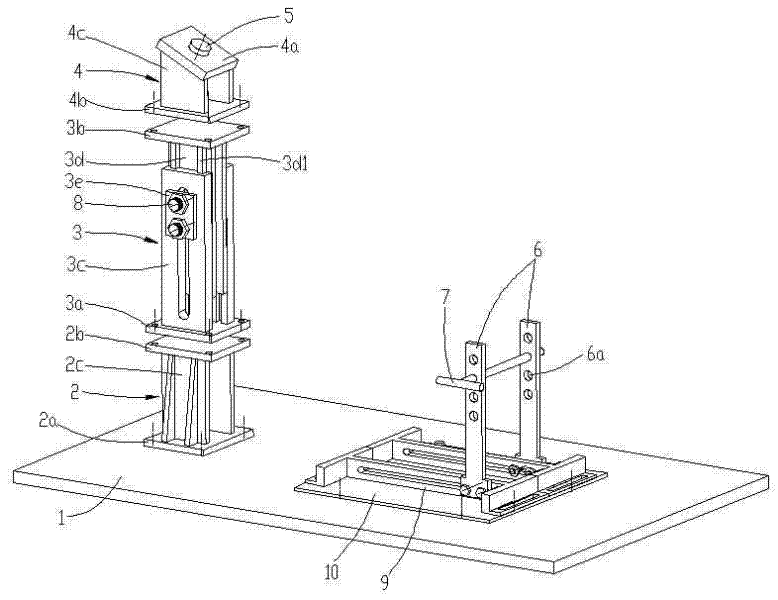

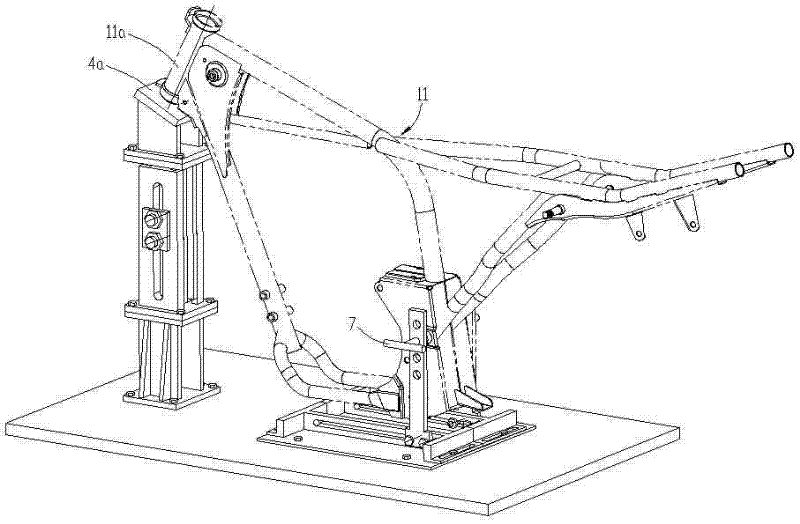

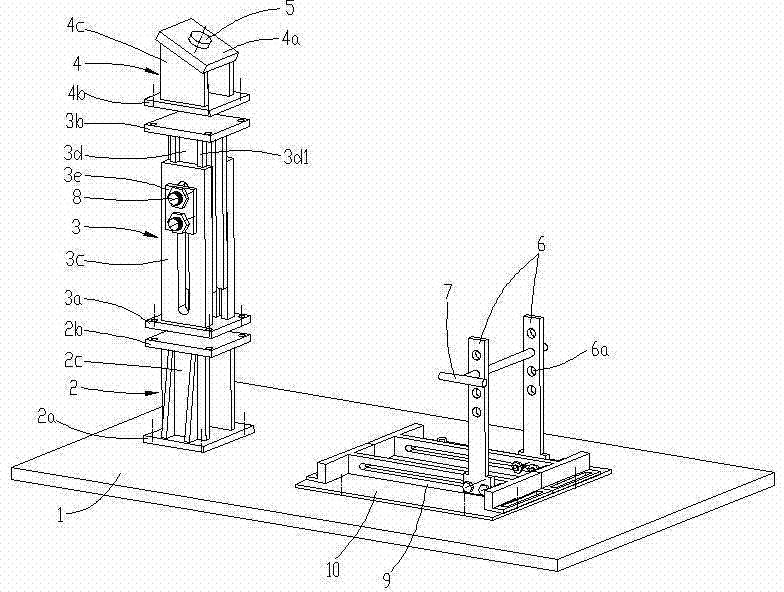

[0018] like figure 1 As shown, the horizontal workbench 1 is a rectangular flat plate structure, and a base 2 is arranged on the plate surface of the front part of the horizontal workbench 1, and the base 2 is composed of a first positioning plate 2a, a second positioning plate 2b and a first vertical plate 2c, Wherein the first positioning plate 2a and the second positioning plate 2b are rectangular, the first positioning plate 2a fits with the horizontal workbench 1, and the four corners of the first positioning plate 2a are fixed with the horizontal workbench 1 by bolts. The upper surface of the first positioning plate 2a is vertically welded with two symmetrical first vertical plates 2c, the tops of the two first vertical plates 2c are welded to the bottom surface of the second positioning plate 2b, and the second positioning plate 2b is located at direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com