Damping spring vibration-proof hammer

A technology of damping springs and anti-vibration hammers, which is applied in the field of shock absorbers, can solve the problems of endangering the safe operation of transmission lines, unsatisfactory wires, and vibration of wires, etc., and achieves good anti-dancing effect, safe and reliable use, and long working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

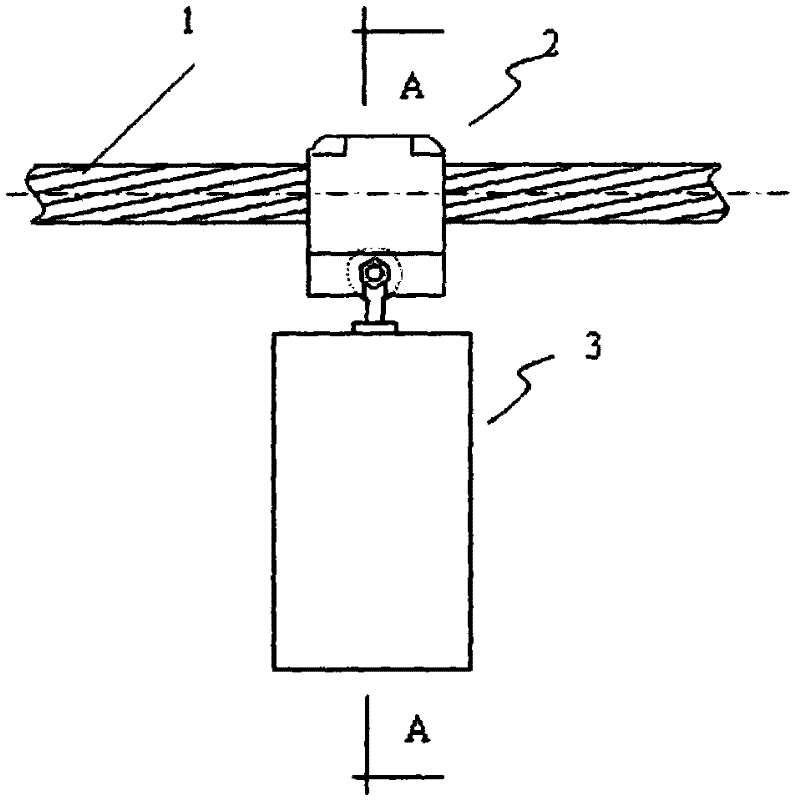

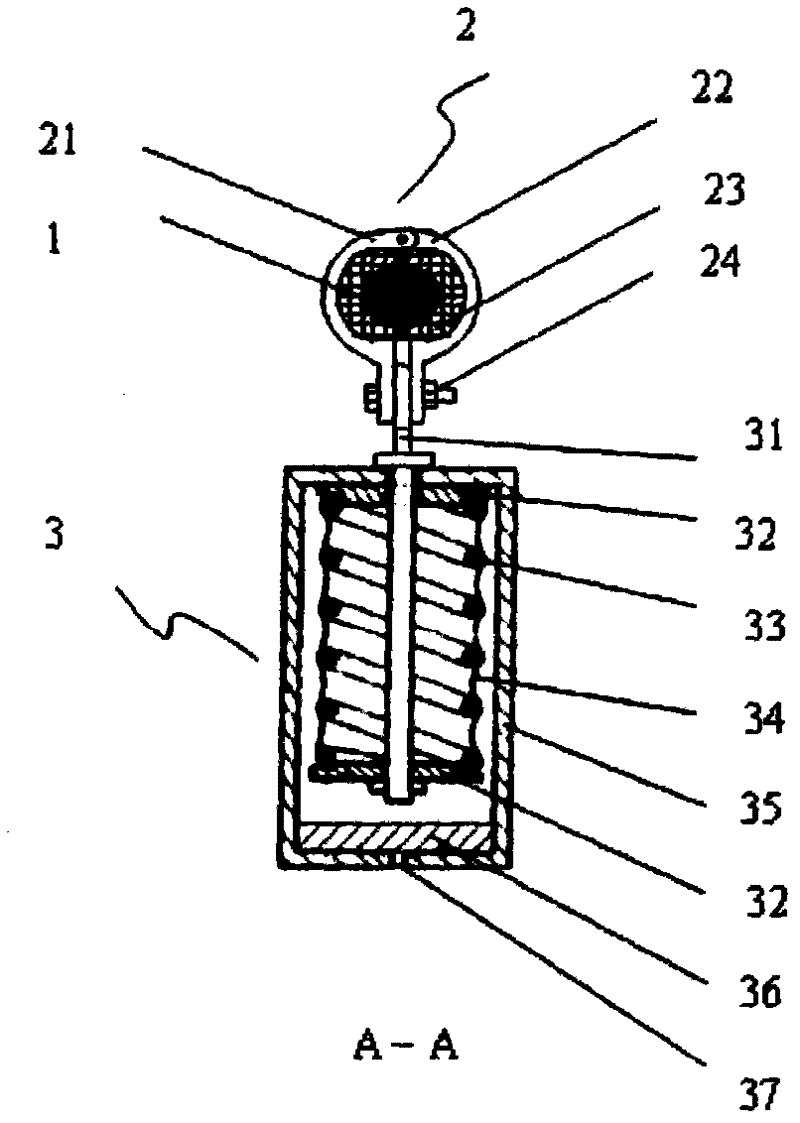

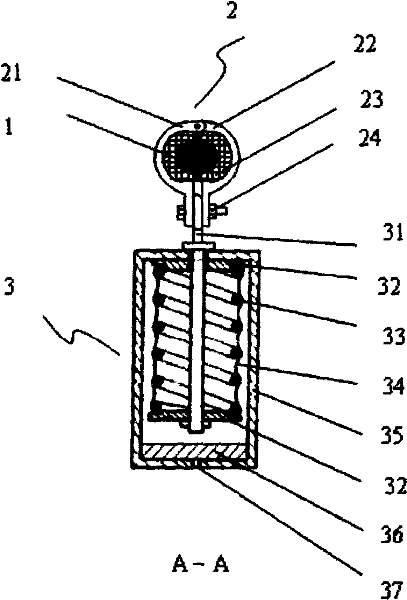

[0019] refer to figure 1 and 2 , The damping spring anti-vibration hammer of the present invention includes a damping spring shock absorber 3 and a wire clip 2 in two parts. The structure of the damping spring shock absorber 3 is to include a cylinder body 1, a piston rod 31 is built in the cylinder body 1, a positioning plate 32 is mounted on the upper and lower ends of the piston rod 31, and a spring 33 is arranged between the positioning plates 32. And damping rubber sleeve 34, damping rubber sleeve 34 is enclosed within on the spring 33. The structure of the clamp 2 is that the upper end of the clamp main body 21 and the clamp gland 22 are hinged, and the lower end of the clamp main body 21, the clamp gland 22 and the upper end of the piston rod 31 of the damping spring shock absorber 3 pass through Self-locking bolt 24 is fixedly connected.

[0020] A counterweight plate 36 is arranged at the bottom of the cylinder body 1 of the damping spring shock absorber 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com