Food purifying machine

A technology of food purifiers and racks, applied in food processing, food preparation, food science, etc., can solve the problems of low ozone solubility, large food damage, human injury, etc., reduce the number of washings with water, and achieve excellent purification effects. The effect is clean and thorough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the food purifier of the present invention will be further described below in conjunction with the accompanying drawings of the description. Realize food purification is convenient, labor-saving, efficient, water-saving, clean and thorough,

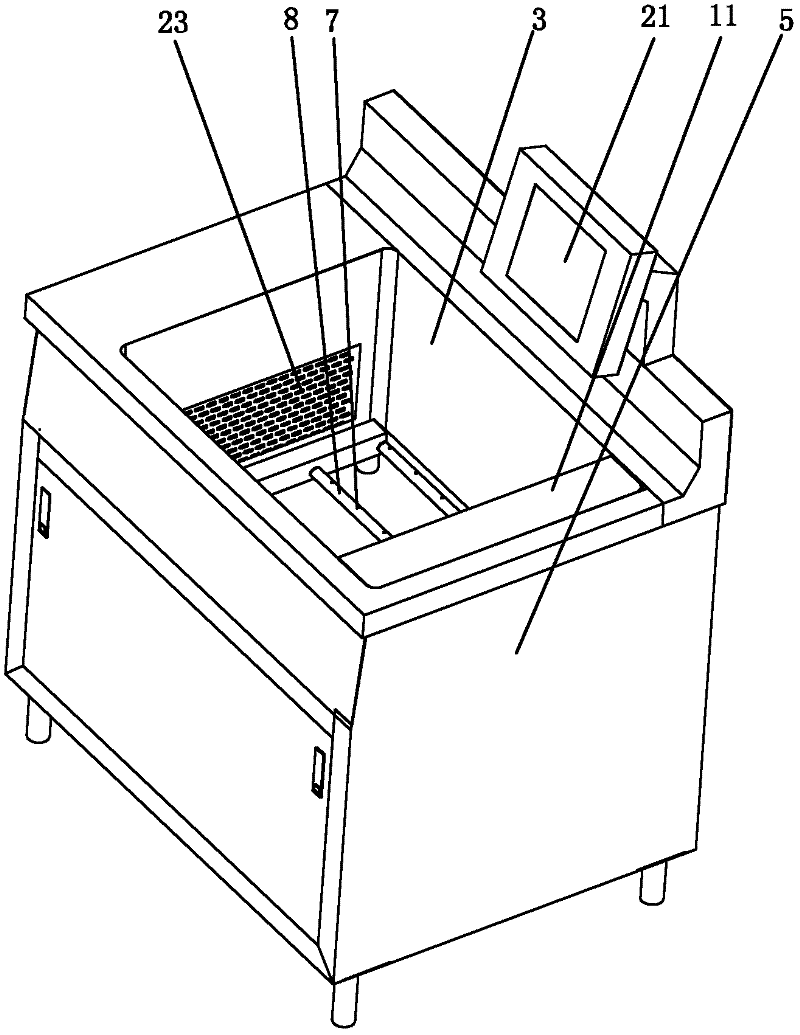

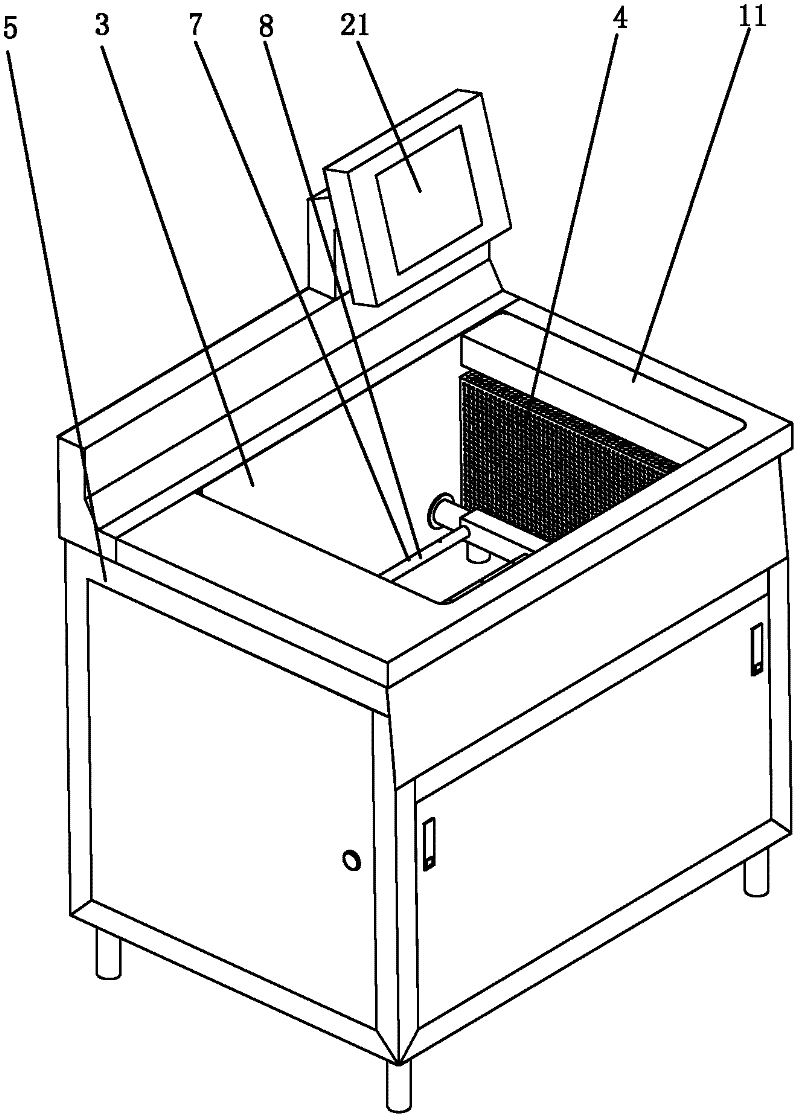

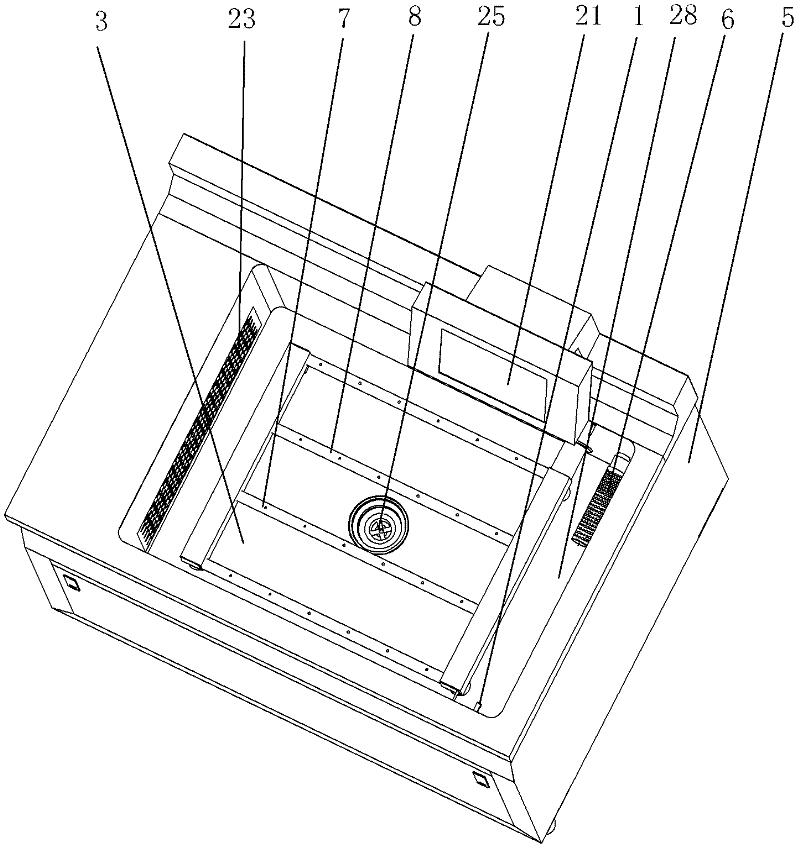

[0037] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10 show the food purifier of the present invention, which includes several main parts of a frame part, a control part, a water catalyst device and an air pump device, wherein:

[0038] The upper part of the frame 5 is provided with a cleaning tank 3, and one side of the cleaning tank 3 is provided with a filter tank 28. There is a filter screen 4 between the cleaning tank 3 and the filter tank 28 to filter out some solid residues and prevent them from entering the water circulation system to cause pipeline blockage. There is a screen cover 11 on the top of the net 4, so that the working machine table is beautiful and smooth, and the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com