Multi-point continuous measurement and simulation method for solidification heat transfer process of molten steel in continuous casting crystallizer

A technology of continuous casting mold and heat transfer process, applied in the field of continuous casting, can solve problems such as unfavorable continuous production, unstable solidification heat transfer, inability to cope with emergencies, etc., and achieve the effect of high applicability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

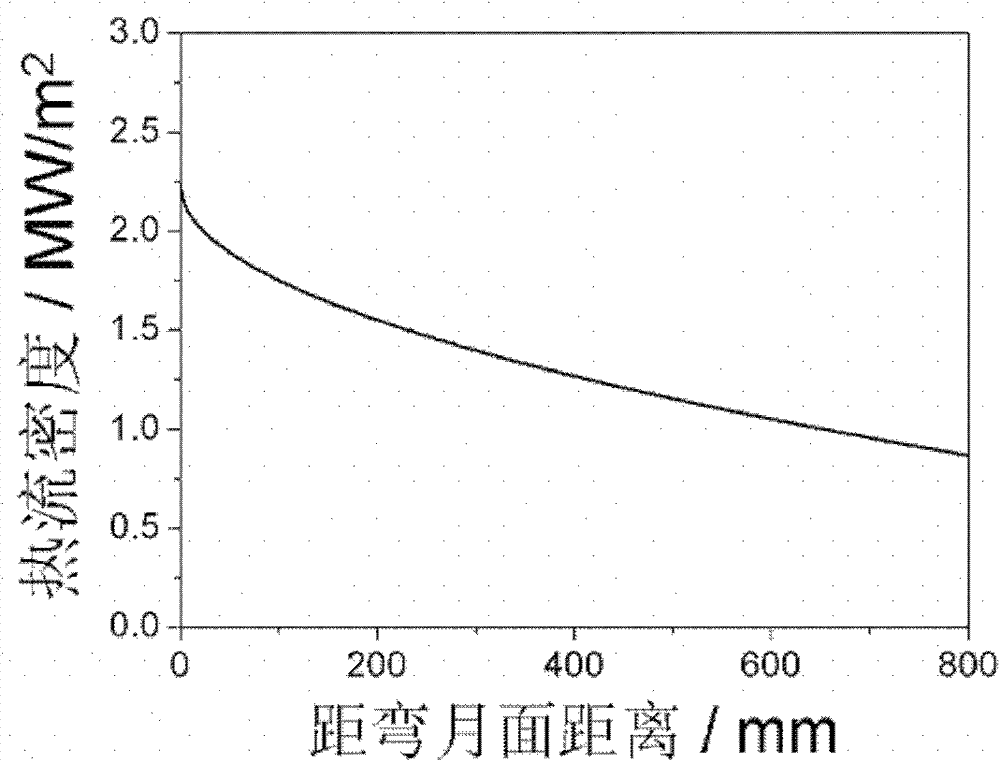

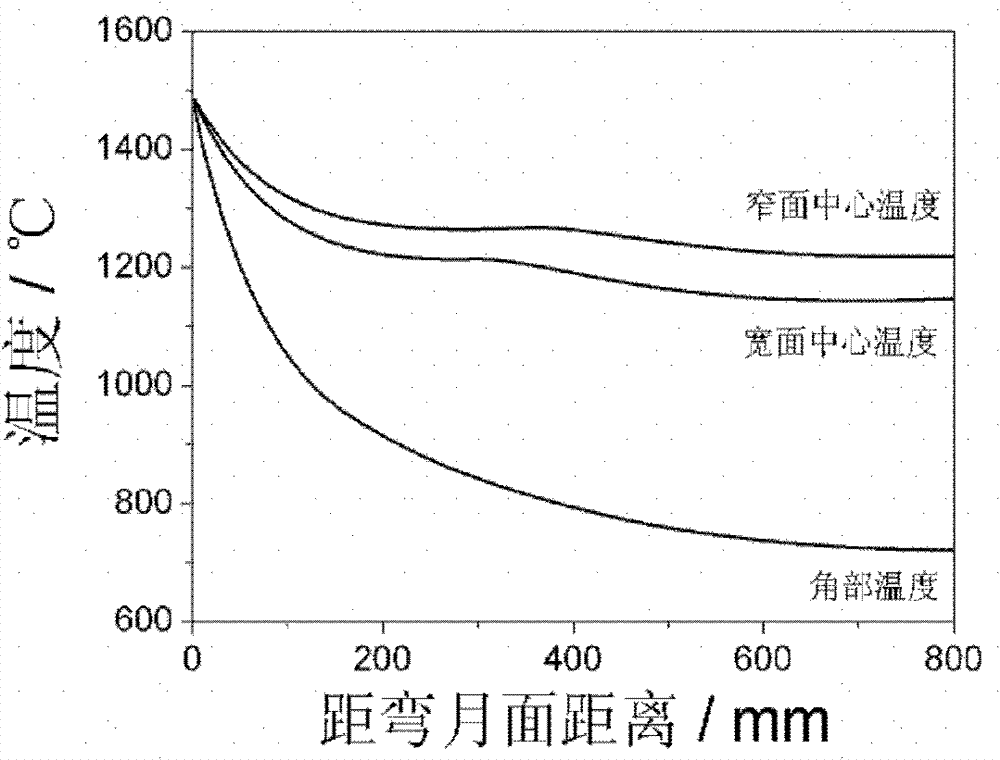

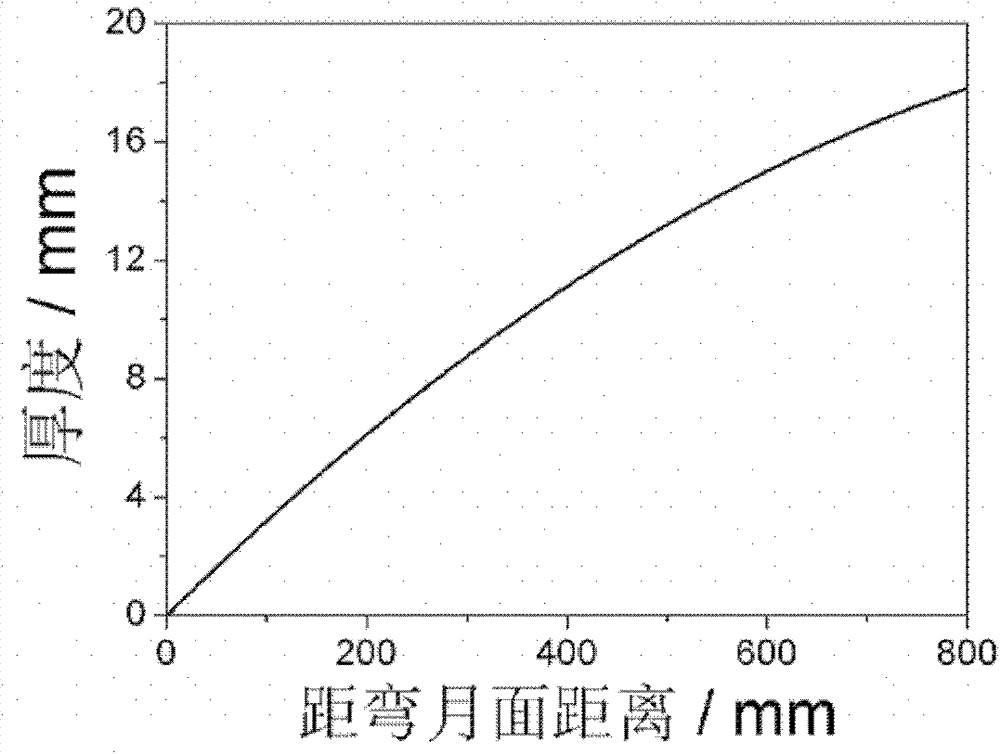

[0032] The multi-point continuous measurement method for simulating the solidification and heat transfer process of molten steel in the continuous casting mold is based on the temperature distribution data obtained by real-time monitoring of the thermocouple on the copper plate of the slab continuous casting machine crystallizer, using different casting machines Parameters, steel type data parameters and production process parameters to convert the heat flux density in the crystallizer, and simulate the solidification and heat transfer process of the high-temperature molten steel in the entire crystallizer. The system is simple, easy to operate, high in applicability, and high in reliability. It can simulate the solidification and heat transfer process of molten steel in the crystallizer of the slab continuous casting machine on-line in real time. Easy way.

[0033] The present invention will be further elaborated below by taking the casting of Stb32 steel on a 1000×200 mm sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com