Method for preparing surface lyophobic oleophobic protection treatment agent

A technology of hydrophobic and oleophobic treatment agent, applied in the field of preparation of stone protection treatment agent, can solve the problems of poor air permeability, poor durability, poor solvent resistance, unsatisfactory oil resistance, etc., so as to increase roughness and enhance amphiphobic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

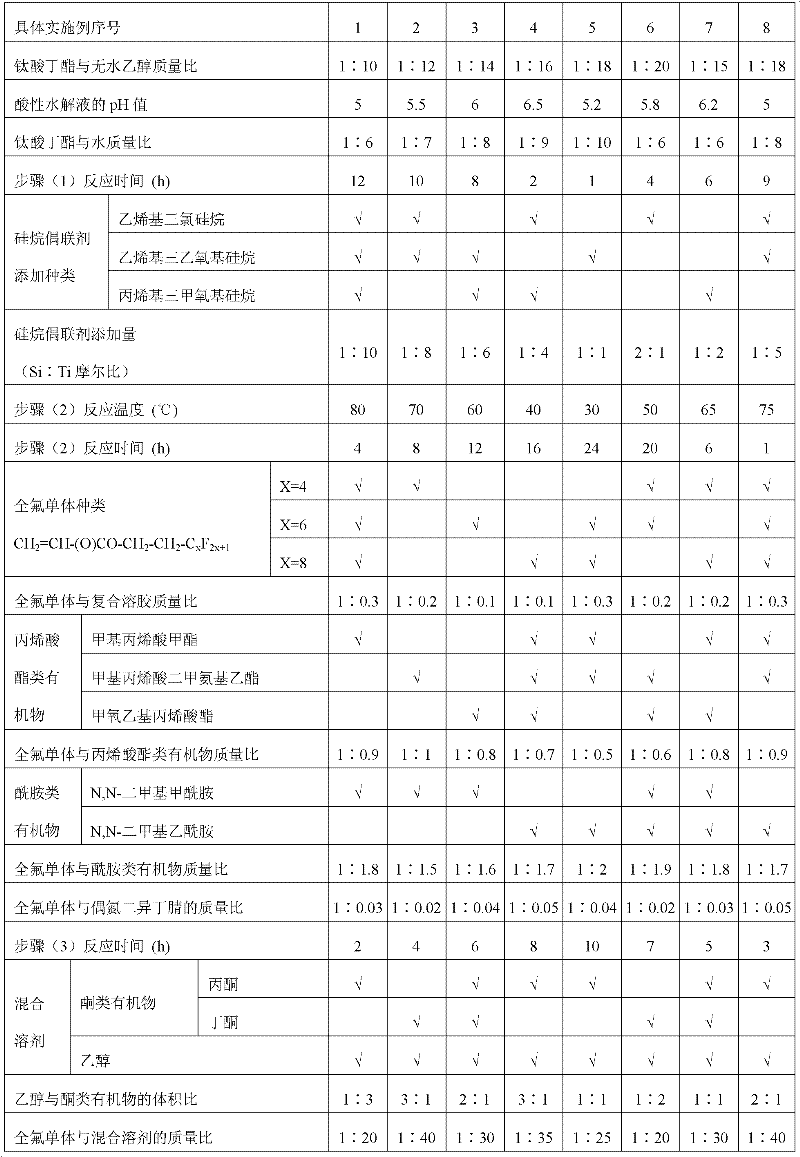

[0015] The present invention is further described by examples below.

[0016] The preparation method of the surface hydrophobic and oleophobic protective treatment agent in the present invention comprises the following steps:

[0017] (1) Mix butyl titanate and absolute ethanol at a mass ratio of butyl titanate to absolute ethanol of 1:10 to 1:20, and then slowly add it to the pH value of 5 to 6.5 as an acidic hydrolyzate In the water, control the amount of water so that the mass ratio of butyl titanate to water is 1:6 to 1:10, and react at 50° C. for 1 to 12 hours to obtain particle-type nano-titanium dioxide sol;

[0018] (2) The silane coupling agent is added to the particle-type nano-titanium dioxide sol at a molar ratio of Si:Ti of 1:10 to 2:1, and the hydrolysis polymerization reaction is carried out for 1 to 24 hours in a water bath at 30 to 80°C to obtain a composite Sol;

[0019] (3) In the composite sol, add perfluoromonomers, acrylates, amides and other organic su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com