A kind of preparation method of light-weight high-strength fishing rod

A high-strength, high-strength fishing rod technology, applied in the field of preparation of light-weight and high-strength fishing rods, can solve problems such as low production efficiency, resin gel reaction, and difficulty in volatilization, and achieve high fatigue strength, excellent mechanical properties, and rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

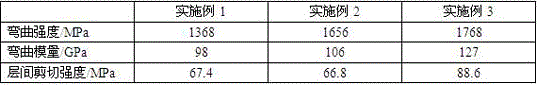

Examples

Embodiment 1

[0027] A method for preparing a lightweight high-strength fishing rod, using carbon fiber cloth as a prepreg cloth, which is pretreated in a coating solution, impregnated with an epoxy resin matrix slurry, and then wrapped around the carbon fiber cloth and cured to obtain a fishing rod blank , the rough is polished, painted and assembled to make a fishing rod. The specific steps are:

[0028] Step 1. Preparation of coating solution:

[0029] (1) According to the weight ratio of 2.5:1, weigh silver nitrate and polyvinyl alcohol powder, dissolve all the silver nitrate in deionized water, add polyvinyl alcohol to the formed silver nitrate solution, and then put it in 70℃ water Heat and stir in a water bath until the polyvinyl alcohol is completely dissolved to form a mixed solution for subsequent use;

[0030] (2) According to the weight ratio of 2.5:1, weigh ethylene glycol and triethanolamine and mix to obtain the mixed solution B, according to the volume ratio of 1:1.5, respe...

Embodiment 2

[0041] A method for preparing a lightweight high-strength fishing rod, using carbon fiber cloth as a prepreg cloth, which is pretreated in a coating solution, impregnated with an epoxy resin matrix slurry, and then wrapped around the carbon fiber cloth and cured to obtain a fishing rod blank , the rough is polished, painted and assembled to make a fishing rod. The specific steps are:

[0042] Step 1. Preparation of coating solution:

[0043] (1) According to the weight ratio of 2.5:1, weigh silver nitrate and polyvinyl alcohol powder, dissolve all the silver nitrate in deionized water, add polyvinyl alcohol to the formed silver nitrate solution, and then put it in 70℃ water Heat and stir in a water bath until the polyvinyl alcohol is completely dissolved to form a mixed solution for subsequent use;

[0044] (2) According to the weight ratio of 2.5:1, weigh ethylene glycol and triethanolamine and mix to obtain the mixed solution B, according to the volume ratio of 1:1.5, respe...

Embodiment 3

[0055] A method for preparing a lightweight high-strength fishing rod, using carbon fiber cloth as a prepreg cloth, which is pretreated in a coating solution, impregnated with an epoxy resin matrix slurry, and then wrapped around the carbon fiber cloth and cured to obtain a fishing rod blank , the rough is polished, painted and assembled to make a fishing rod, which is characterized in that the specific steps are:

[0056] Step 1. Preparation of coating solution:

[0057] (1) According to the weight ratio of 2.5:1, weigh silver nitrate and polyvinyl alcohol powder, dissolve all the silver nitrate in deionized water, add polyvinyl alcohol to the formed silver nitrate solution, and then put it in 70℃ water Heat and stir in a water bath until the polyvinyl alcohol is completely dissolved to form a mixed solution for subsequent use;

[0058] (2) According to the weight ratio of 2.5:1, weigh ethylene glycol and triethanolamine and mix to obtain the mixed solution B, according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com