Flavor blending liquid and preparation method thereof

A technology for flavoring liquid and mixture, which is applied in the field of winemaking, can solve the problems of less protein utilization, low utilization rate of warming yellow water, environmental pollution, etc., and achieves the effects of prominent flavor characteristics, improved utilization value, and low taste threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 adopts the present invention to prepare flavoring liquid

[0030] a, according to (85 parts of yellow water, 15 parts of high-temperature Daqu) weight ratio, 340 kg of yellow water and 60 kg of high-temperature Daqu are mixed to obtain a liquid-solid mixture (alcohol content in the mixture is 6% vol);

[0031] b. The liquid-solid mixture is sealed and heated at 80°C for 4 hours every day for a total of 8 days;

[0032] c. After heating, filter to obtain flavoring solution.

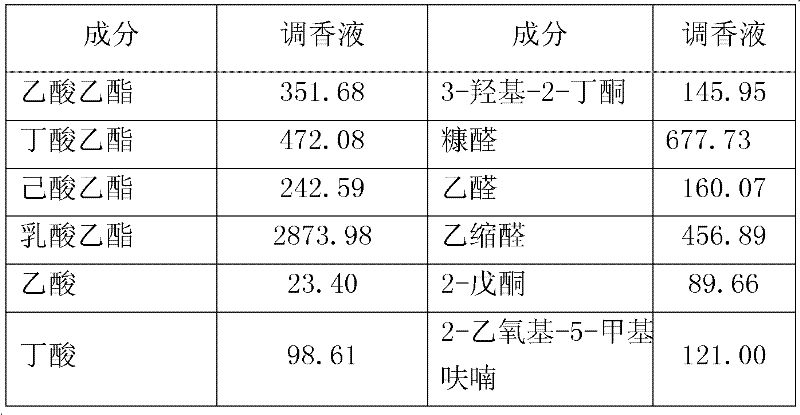

[0033] Table 1 Main fragrance components of flavoring liquid (mg / L)

[0034]

[0035]

Embodiment 2

[0036] Embodiment 2 adopts the present invention to prepare flavoring liquid

[0037] a, according to (80 parts of yellow water, 20 parts of high-temperature Daqu) weight ratio, 320 kg of yellow water and 80 kg of high-temperature Daqu are mixed to obtain a liquid-solid mixture (alcohol content in the mixture is 7% vol);

[0038] b. The liquid-solid mixture is sealed and heated at 80°C for 3 hours every day for a total of 6 days;

[0039] c. After heating, filter to obtain flavoring solution.

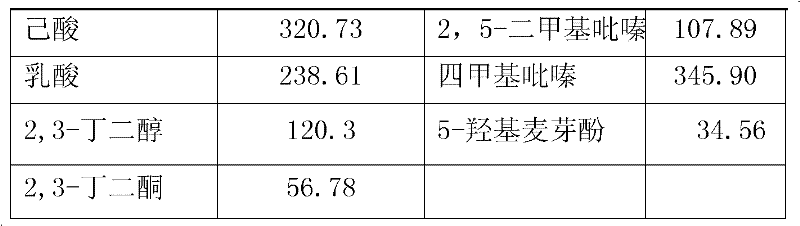

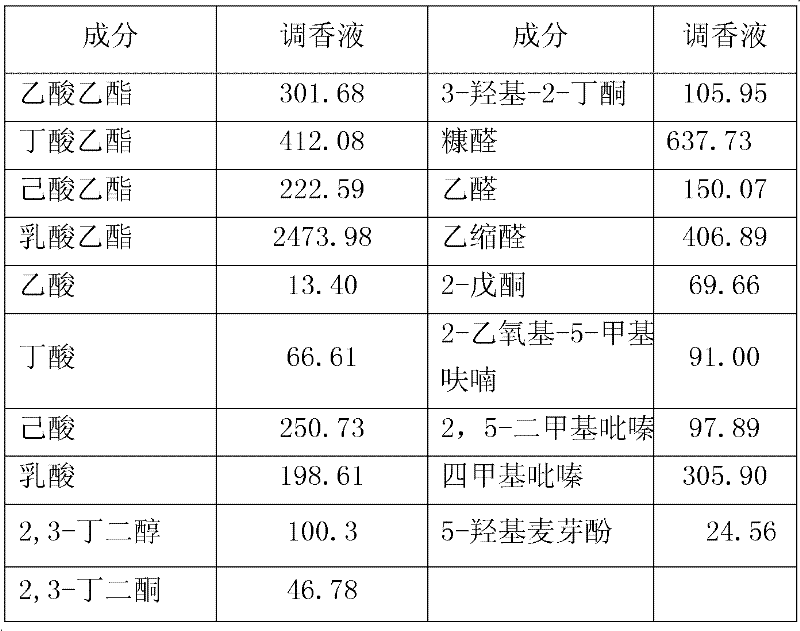

[0040] The main components of the prepared flavoring liquid are shown in Table 2.

[0041] Table 2 Main fragrance components of flavoring liquid (mg / L)

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com