Automobile dual-mass flywheel with continuous varied stiffness and high torque

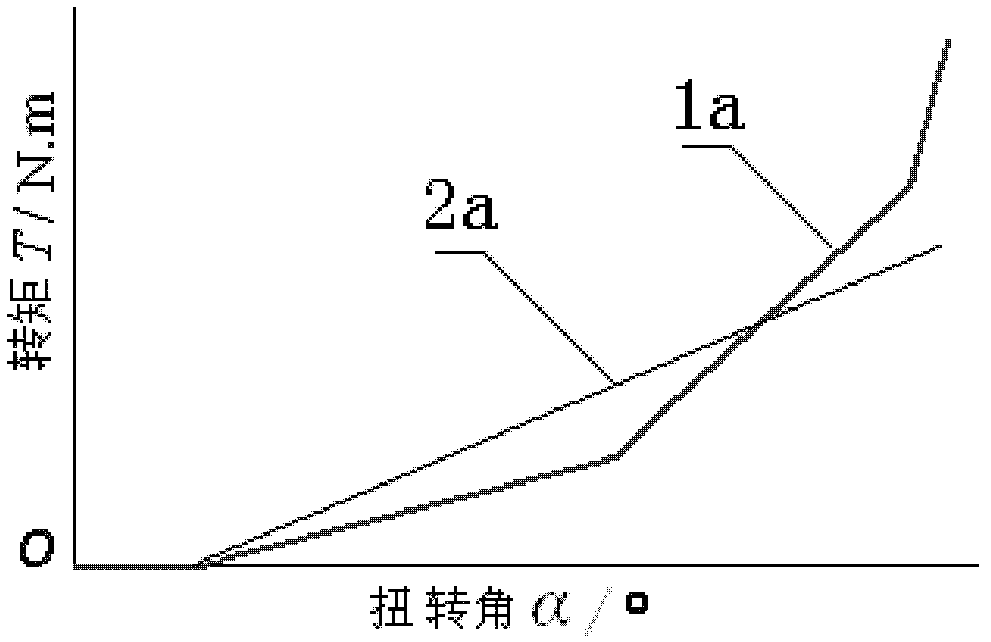

A dual-mass flywheel and high-torque technology, applied in flywheels and other directions, can solve problems such as sudden changes in stiffness, sudden changes in stiffness, and difficulty in meeting the requirements of large torques, so as to avoid impact loads and noises, improve buffering capacity, and withstand The effect of small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

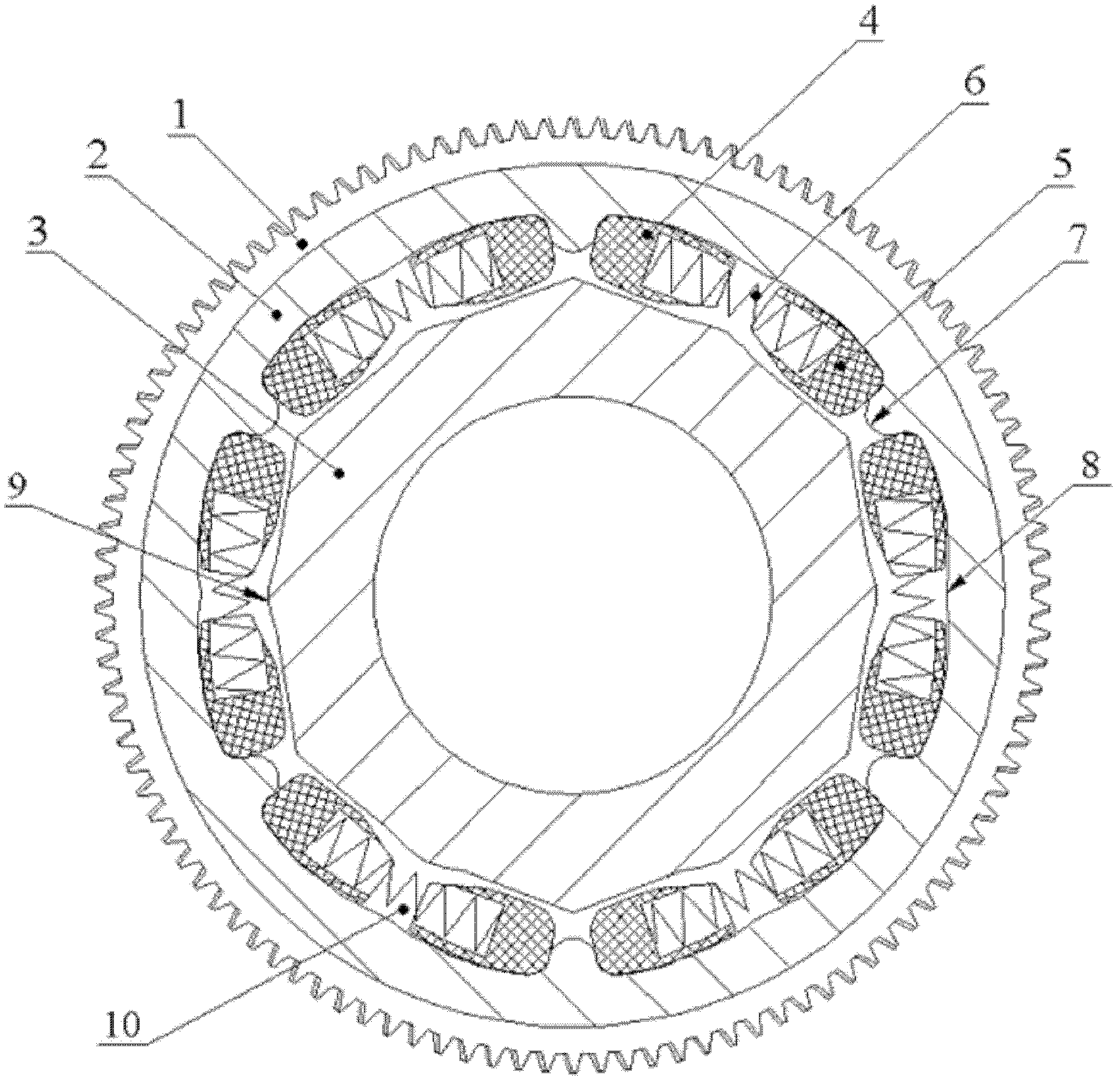

[0091] Dual-mass flywheel for 2.0L car engine, the structure is as follows figure 2 shown.

[0092] The maximum output torque / speed of the engine is 185N.m / 4500rpm, the idle speed of the engine is 750rpm, the maximum speed is 7000rpm, and the common speed is 2500-4500rpm.

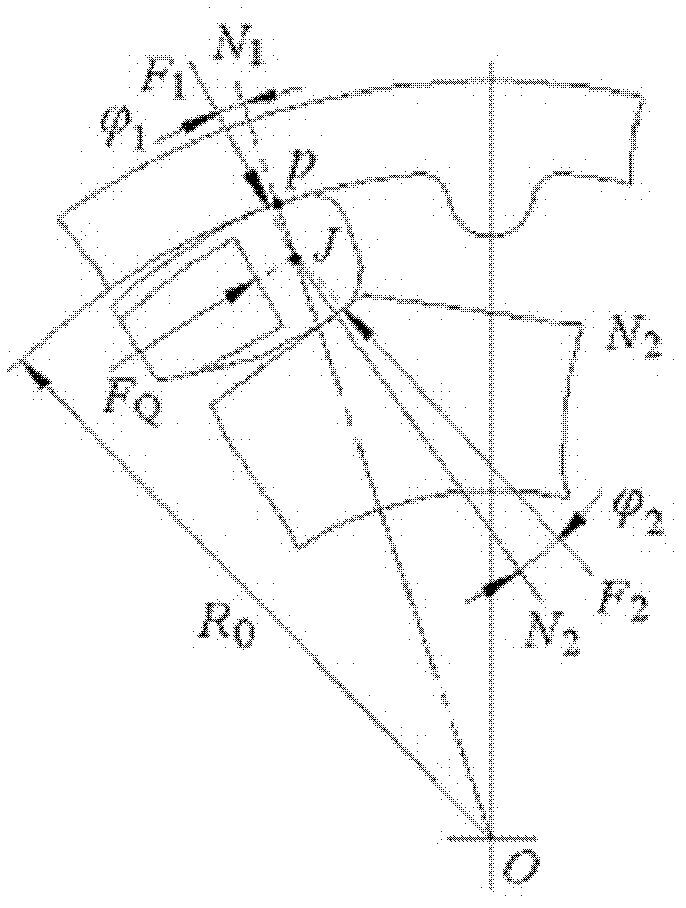

[0093] The parameters are as follows: Six sets of shock absorbers are used, the diameter of the damping spring steel wire of the shock absorber is d=2.1mm, and the middle diameter is D 0 =15.3mm, pitch P=5.8mm, effective number of turns n=10.5, initial length of damping spring L 0 =66mm, preload length Lj=65mm, damping spring line stiffness k t =5.17N / mm, distribution radius R 3 =112.5mm, the maximum diameter R of the inner wall of the primary flywheel 0 =127.75mm, corrected arc radius R 1 =105mm, radius R of circumscribed circle of secondary flywheel 2 =106.1mm, apex angle γ=139°, idle angle θ=3, friction damping bearing torque M f =7N.m, η=6.5°, Δr max =2.29mm, allowable maximum torsion angle α ...

Embodiment 2

[0100] 2.3L-2.4L car engine dual-mass flywheel, the structure is as follows figure 2 shown.

[0101] The maximum output torque / speed of the engine is 220-240N.m / 4200rpm, the idle speed of the engine is 800rpm, the maximum speed is 6500rpm, and the common speed is 2500-4500rpm.

[0102] The parameters are as follows: Six sets of shock absorbers are used, the diameter of the damping spring steel wire of the shock absorber is d=2.3mm, and the middle diameter is D 0 =15.3mm, pitch P=5.9mm, number of effective turns n=10.5, initial length of damping spring L 0 =67mm, preload length Lj=66mm, damping spring line stiffness k t =7.44N / mm, distribution radius R 3 =112.5mm, the maximum diameter R of the inner wall of the primary flywheel 0 =127.75mm, corrected arc radius R 1 =105mm, radius R of circumscribed circle of secondary flywheel 2 =106.1mm, apex angle γ=139°, idle angle θ=3, friction damping bearing torque M f =7N.m, η=6.5°, Δr max =2.29mm, allowable maximum torsion angl...

Embodiment 3

[0109] 3.0L car engine dual mass flywheel, the structure is as follows Figure 14 shown.

[0110] The maximum output torque / speed of the engine is 295N.m / 4500rpm, the idle speed of the engine is 800rpm, the maximum speed is 6500rpm, and the common speed is 2000~4500rpm.

[0111] The parameters are as follows: Five sets of shock absorbers are used, the diameter of the damping spring steel wire of the shock absorber is d=2.5mm, and the middle diameter is D 0 =15.3mm, pitch P=6.1mm, effective number of turns n=13.5, initial length of damping spring L 0 =88mm, preload length Lj=87mm, damping spring wire stiffness k t =8.08N / mm, distribution radius R 3 =112.5mm, the maximum diameter R of the inner wall of the primary flywheel 0 =127.75mm, corrected arc radius R 1 =105mm, radius R of circumscribed circle of secondary flywheel 2 =108.2mm, apex angle γ=132°, idle angle θ=3, friction damping bearing torque M f =10N.m, η=6.5°, Δr max =3.60mm, allowable maximum torsion angle α m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com