Modular heat radiator for LED lamps

A technology of LED lamp module and heat sink, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., which can solve the problems of slow natural heat release, reduced service life of lamps, and brightness attenuation and other problems, to achieve the effect of small consumables, light weight, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

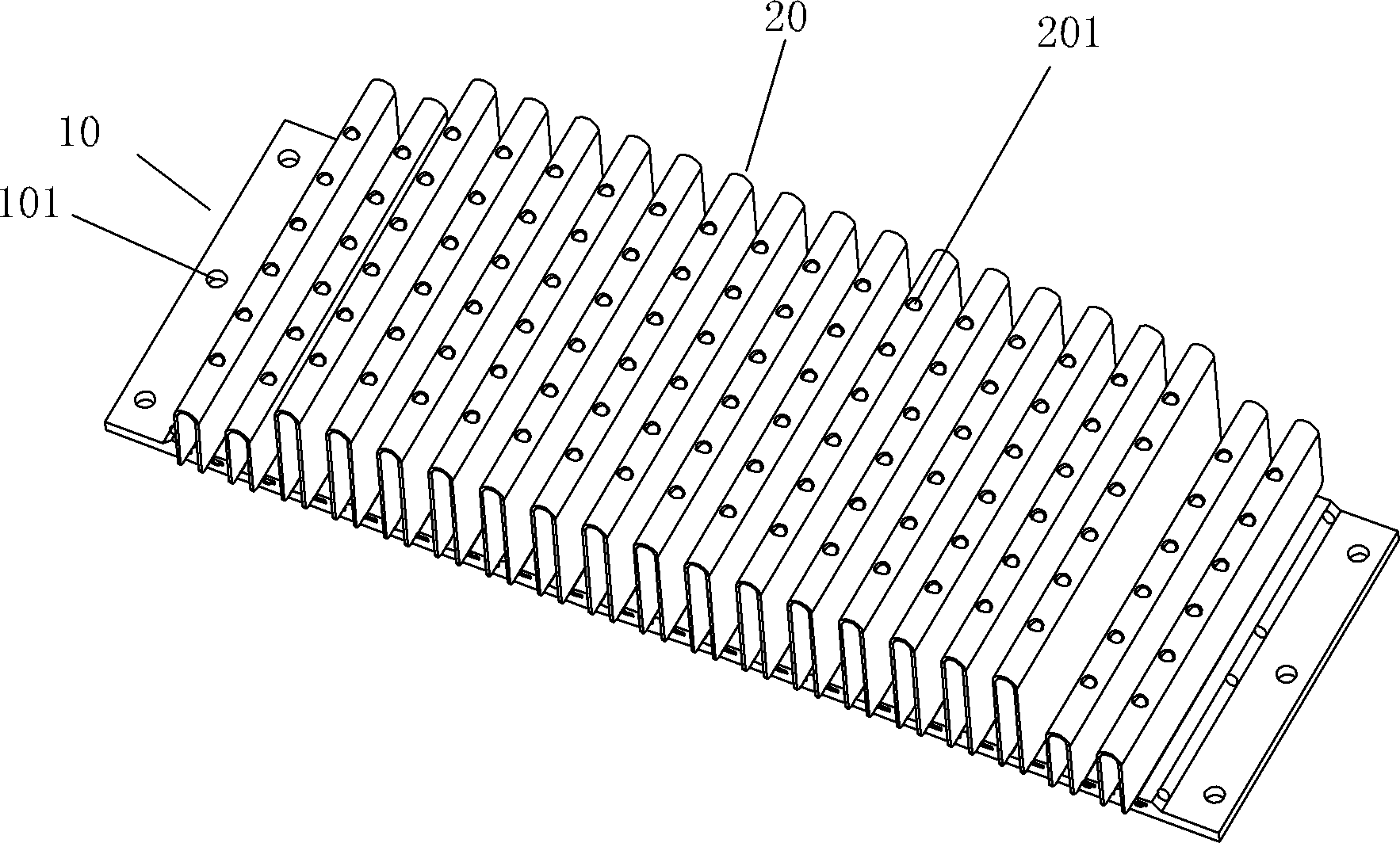

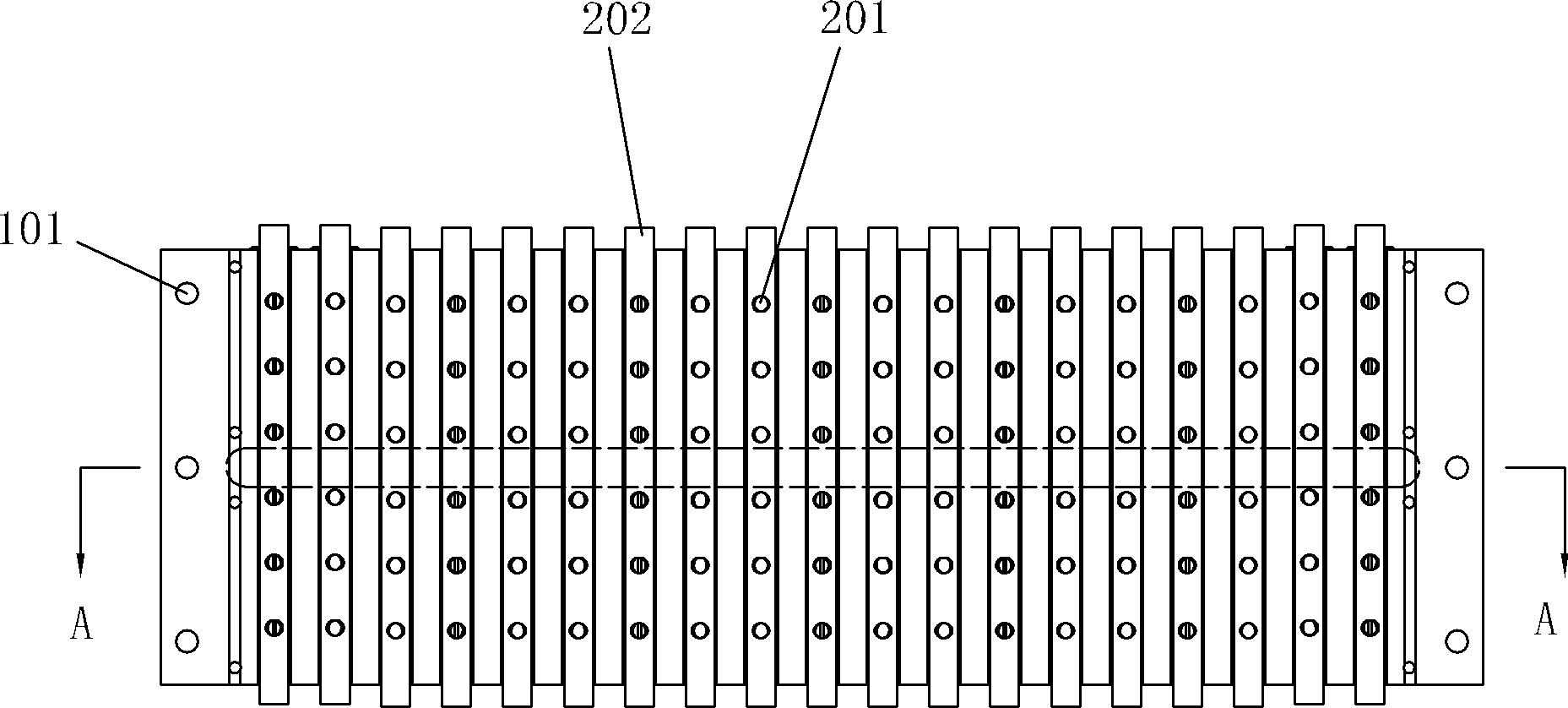

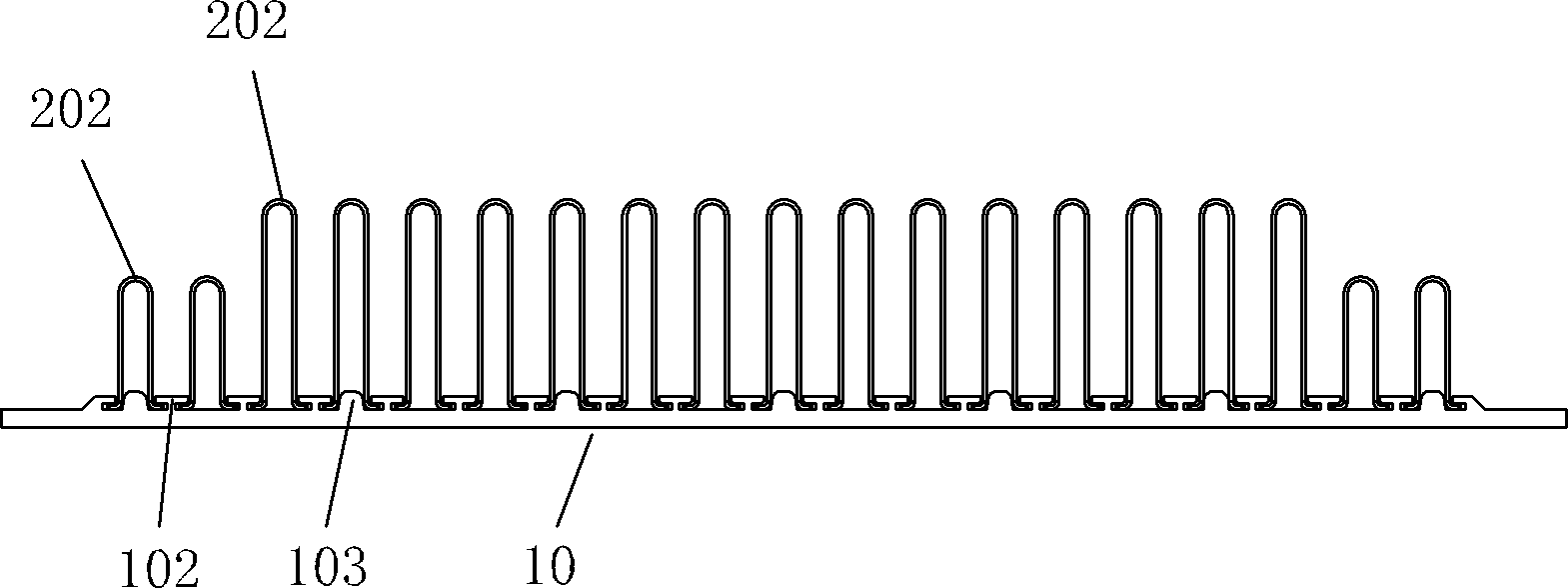

[0022] The present invention will be further described below with specific embodiments, referring to figure 1 -6:

[0023] An LED lamp module type heat sink includes heat dissipation fins 20 and a heat dissipation base plate 10. The heat dissipation base plate 10 is uniformly distributed with a row of T-shaped convex columns 102, and a row of T-shaped convex columns 102 is formed between adjacent two convex columns 102. The heat dissipation fin mounting groove 105 is provided with a heat dissipation fin 20 on the heat dissipation fin mounting groove 105. The two sides of the opening of the lower part of the heat dissipation body 202 of the heat dissipation fin 20 are respectively extended with mounting feet 203. The mounting feet 203 are provided with In the heat dissipation fin mounting slot 105 , a row of heat dissipation holes 201 is provided at the top of the heat dissipation body 202 of the heat dissipation fin 20 , and a strip communicated with all the openings in the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com