Stichopus japonicus powder feed and processing method thereof

A processing method and powder technology are applied in the field of sea cucumber powder feed and its processing, which can solve the problems of hindering the development of sea cucumber aquaculture, slow production speed, low absorption and utilization rate, etc. The rate and absorption utilization rate are improved, and the stretchability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

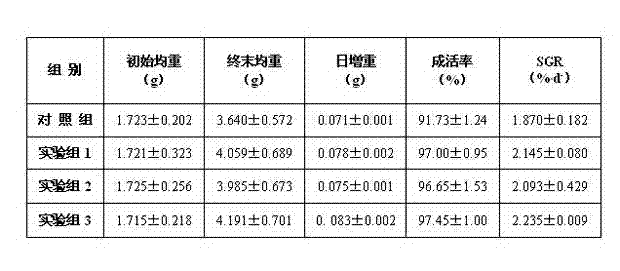

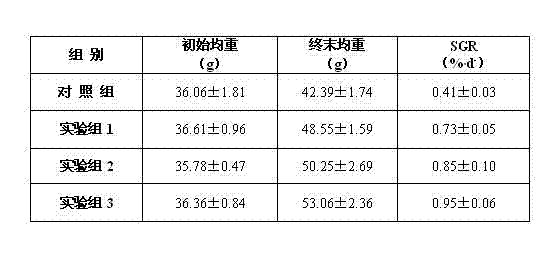

Embodiment 1

[0019] Sea cucumber powder feed, calculated by weight percentage, includes the following ingredients: degummed kelp dry powder 30%; sargassum dry powder 10%; sargassum dry powder 15%; Ulva dry powder 8%; fish meal 5%; yeast powder 4% ; Multivitamins 1%.

[0020] Multivitamins include vitamins B1, B2, B6, B2, stable VC, niacin, folic acid, calcium pantothenate, inositol, choline chloride, and two or more of vitamins A, D3, E, and K3.

Embodiment 2

[0022] Sea cucumber powder feed, calculated by weight percentage, includes the following ingredients: 40% degummed kelp dry powder; 15% sargassum dry powder; 20% sargassum dry powder; 10% Ulva dry powder; 8% fish meal; 6% yeast powder ; Multivitamins 2%. The multivitamins include vitamin B1, B2, B6, B2, stable VC, niacin, folic acid, calcium pantothenate, inositol, choline chloride, and two or more of vitamins A, D3, E, K3 and other multivitamins .

Embodiment 3

[0024] Sea cucumber powder feed, calculated by weight percentage, includes the following ingredients: degummed kelp dry powder 50%; sargassum dry powder 20%; sargassum dry powder 25%; Ulva dry powder 13%; fish meal 12%; yeast powder 8% ; Multivitamin 3%. The multivitamins include vitamin B1, B2, B6, B2, stable VC, niacin, folic acid, calcium pantothenate, inositol, choline chloride, and two or more of vitamins A, D3, E, K3 and other multivitamins .

[0025] The sea cucumber powder feed processing method of above embodiment, its processing flow is:

[0026] Raw material collection → kelp degumming → raw material drying → raw material mixing → coarse crushing → mixing with fish meal → superfine crushing → packaging.

[0027] The specific processing steps are as follows:

[0028] 1) First, collect the required raw materials according to the above-mentioned composition ratio for later use;

[0029] 2), degumming the kelp in it to obtain degumming kelp;

[0030] 3) Dry the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com