Anti-overflow electric pressure cooker and cooking method thereof

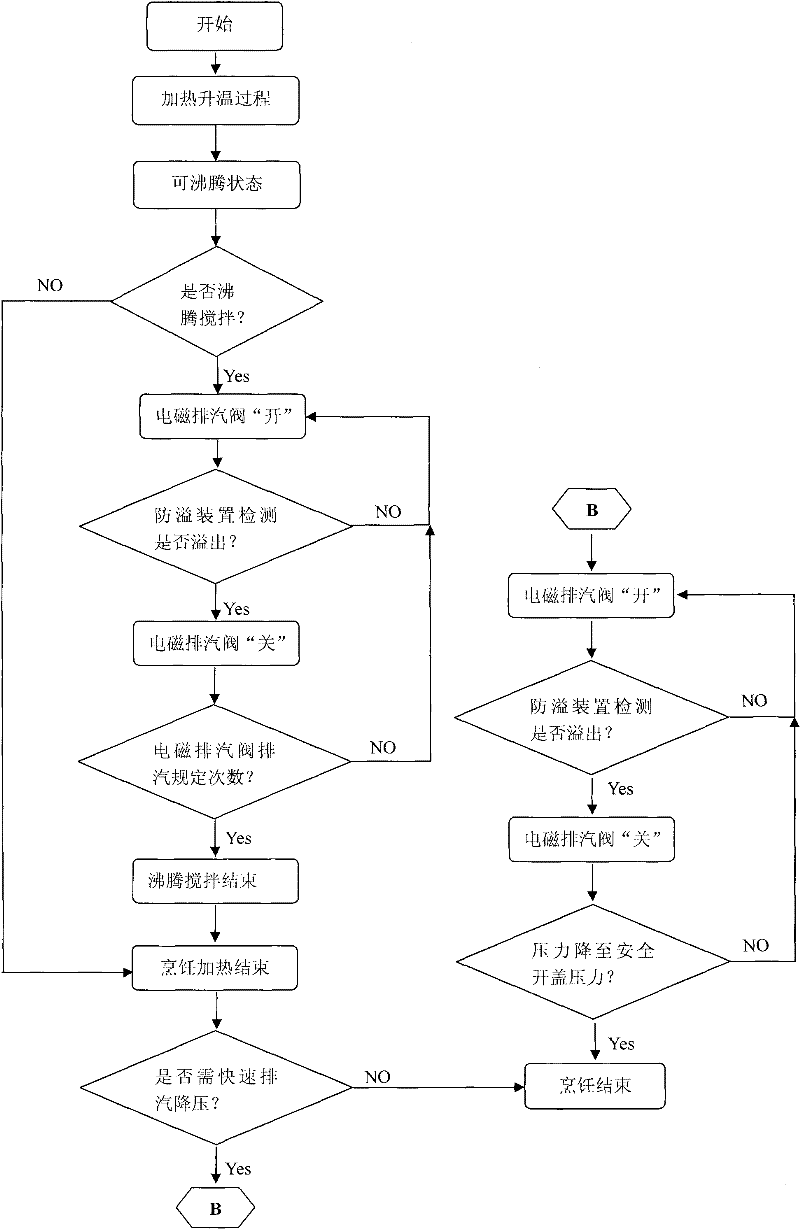

An electric pressure cooker and anti-overflow technology, which is applied in the direction of anti-overflow, cooking utensils, household utensils, etc., can solve the problems of uneven heating of food, long cooling time, cooking dead corners, etc., to improve the taste and color, eliminate cooking dead corners, reduce The effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

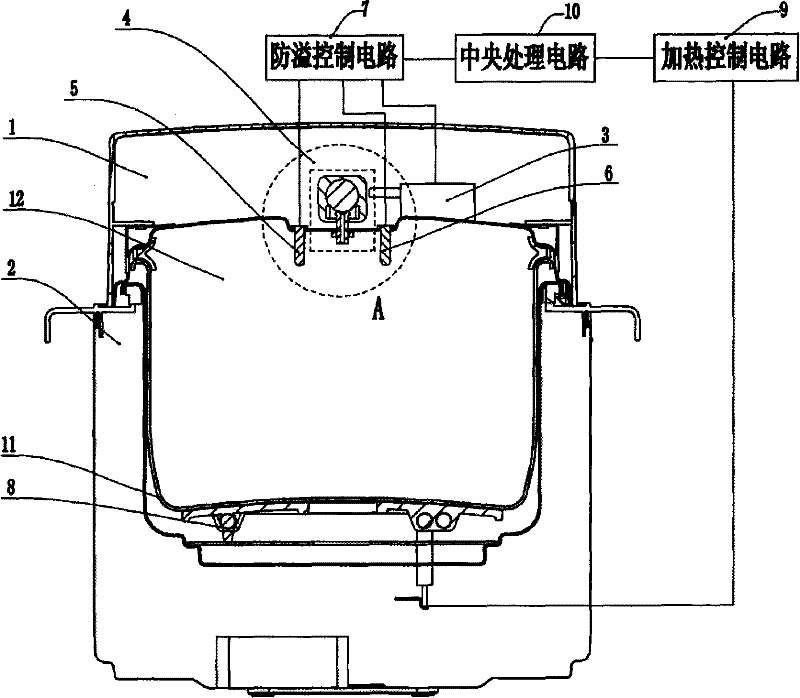

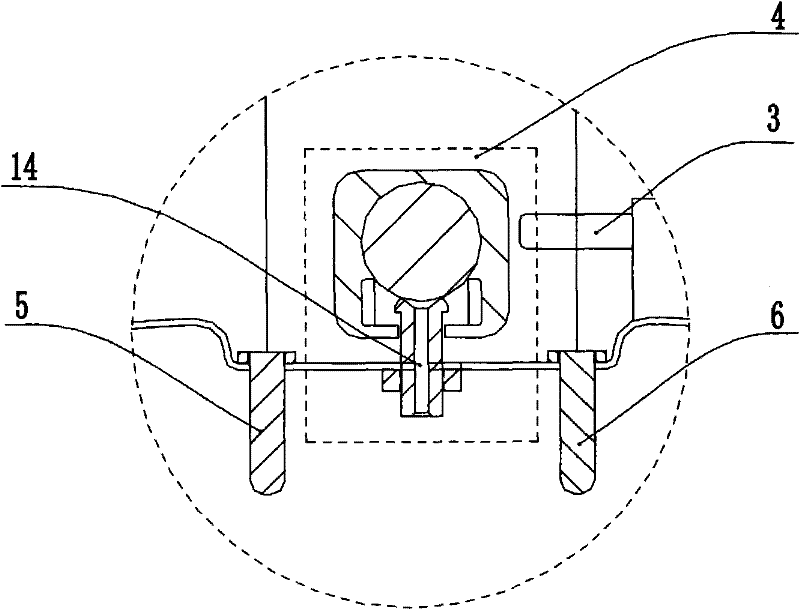

[0027] Such as figure 1 , figure 2 An anti-overflow electric pressure cooker shown includes a pot body 2, a pot liner 11 inserted into the pot body 2, a pot cover 1 for sealing the mouth of the pot liner 11, an electric heating device 8 for heating the pot liner 11, and the electric heating device 8 is controlled to work In the present embodiment, the heating device 8 is an electric heating plate, and a cooking cavity 12 is formed between the pot gall 11 and the pot cover 1, and the pot cover 1 is provided with an electromagnetic exhaust valve for quick steam exhaust, and the electromagnetic exhaust valve includes Solenoid valve 3 and pressure-limiting valve 4, pressure-limiting valve 4 comprises exhaust pipe 13, and described anti-overflow pressure cooker also comprises the anti-overflow device that can prevent liquid from overflowing when exhausting steam rapidly, and described anti-overflow device comprises first electrode 5 and the second electrode 6, the first electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com