Automatic tail rope rolling and releasing manual capstan

An automatic retractable and tail rope technology, applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as fatigue of pulling personnel, human transportation of batteries, and sustainable impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

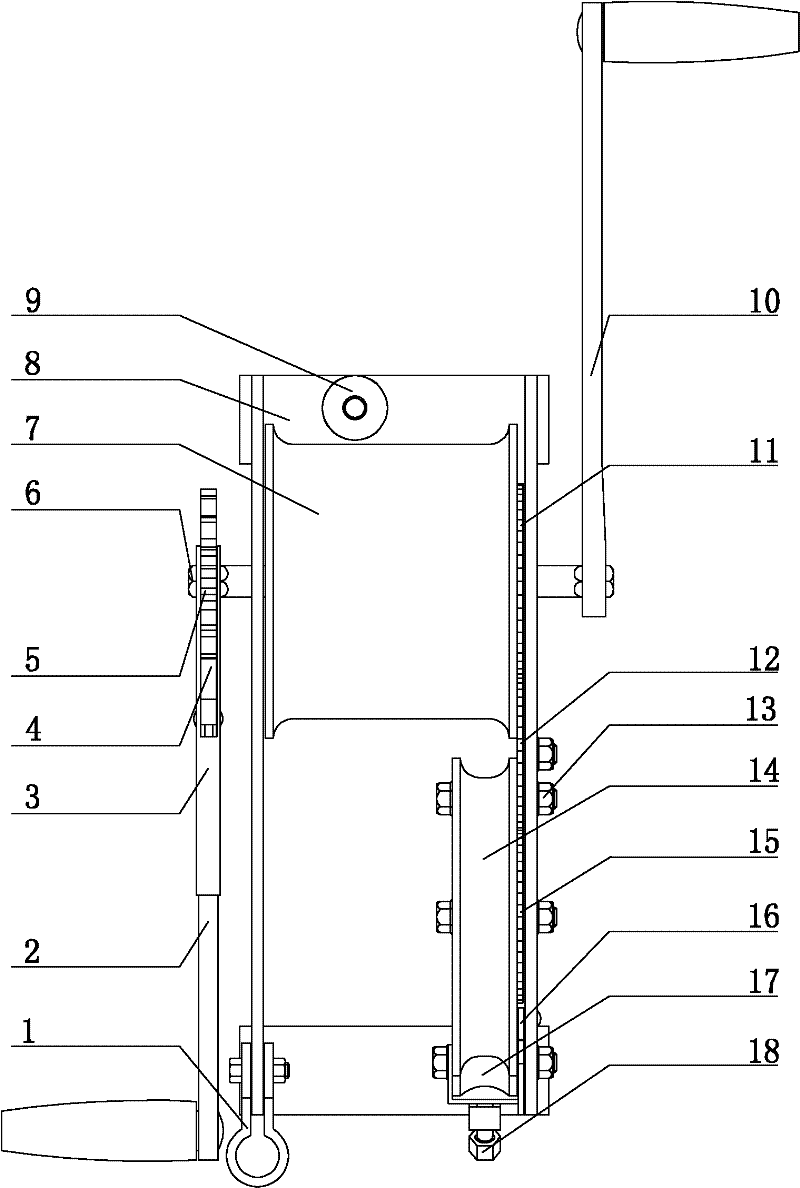

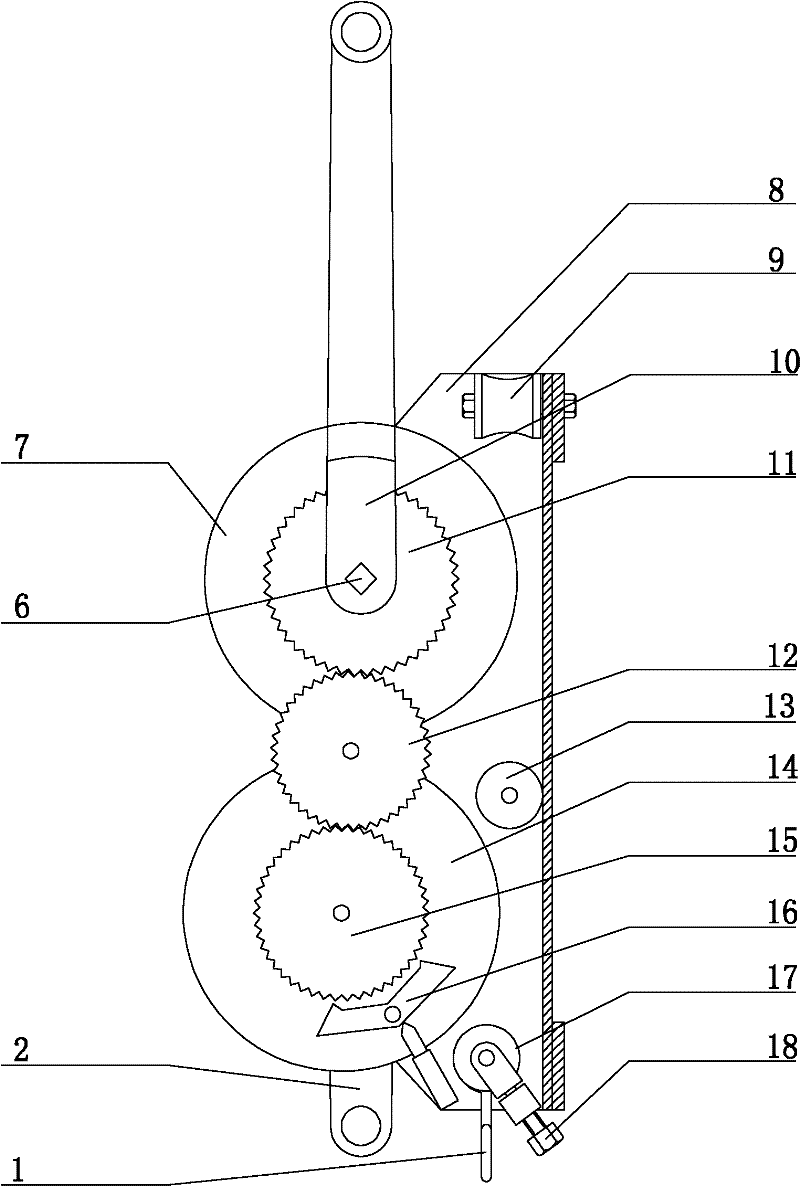

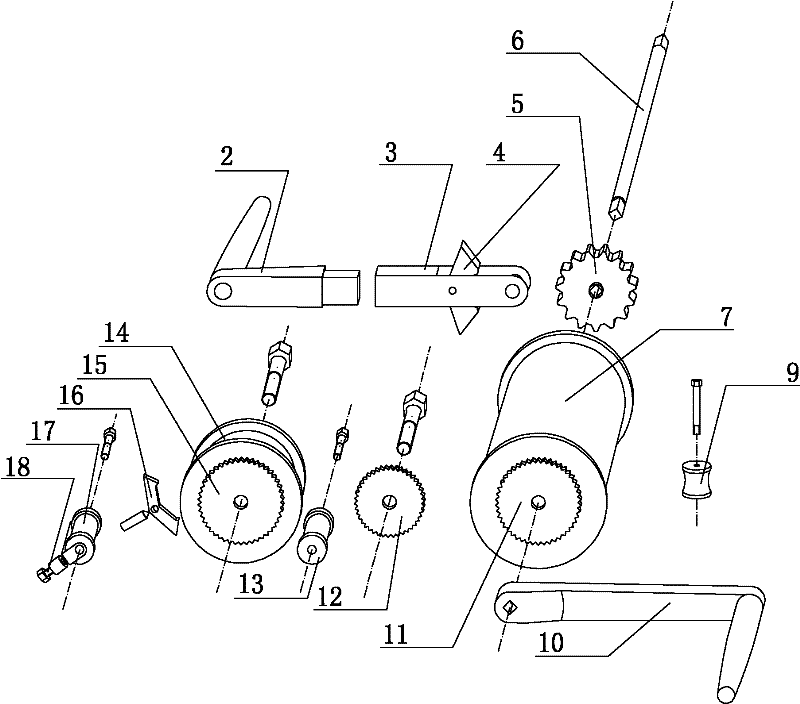

[0014] The bracket 8 of the present invention is used to carry the lifting weight and install parts. A ground anchor connecting ring 1 is installed at the left rear end of the bracket, which is connected to the lifting ground anchor. The left rocker arm 3 is provided with a front bidirectional pawl 4 and a grinding mandrel 6. The upper and outer matching ratchets 5 cooperate, and the left rocker arm 3 is connected with the movable rocker arm 2, which is used for lifting heavier objects. The movable rocker arm 2 can be disassembled according to the lifting needs. The left rocker arm 3 and the right rocker arm 10 are arranged at both ends of the grinding mandrel 6; The axis of the wheel 9 is perpendicular to the axis of the U-shaped groove grinding core 7 at the same time, so as to prevent the grinding rope from winding and running; The right end surface of the groove grinding core 7 is equipped with a driving gear 11, the driving gear 11 drives the intermediate gear 12 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com