Machine for gathering discrete metal from smelting slags

A metal and tailings technology, applied in the field of smelting tailings discrete metal aggregator, can solve the problems of less profit, less income, more cost, etc., and achieve the effects of reducing pollution, creating high efficiency and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

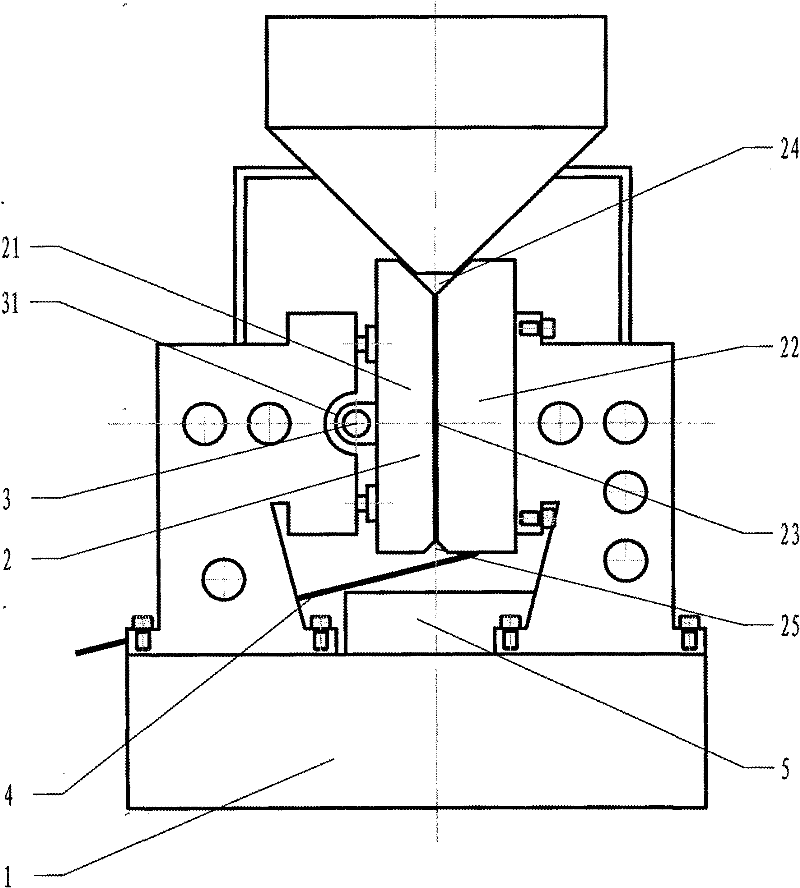

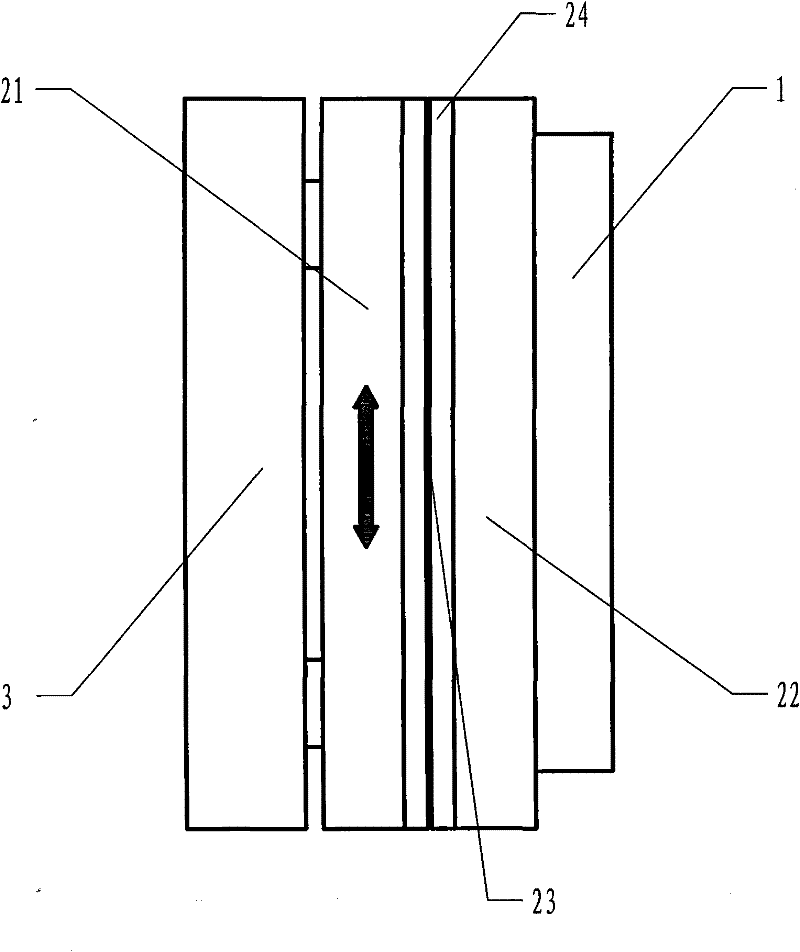

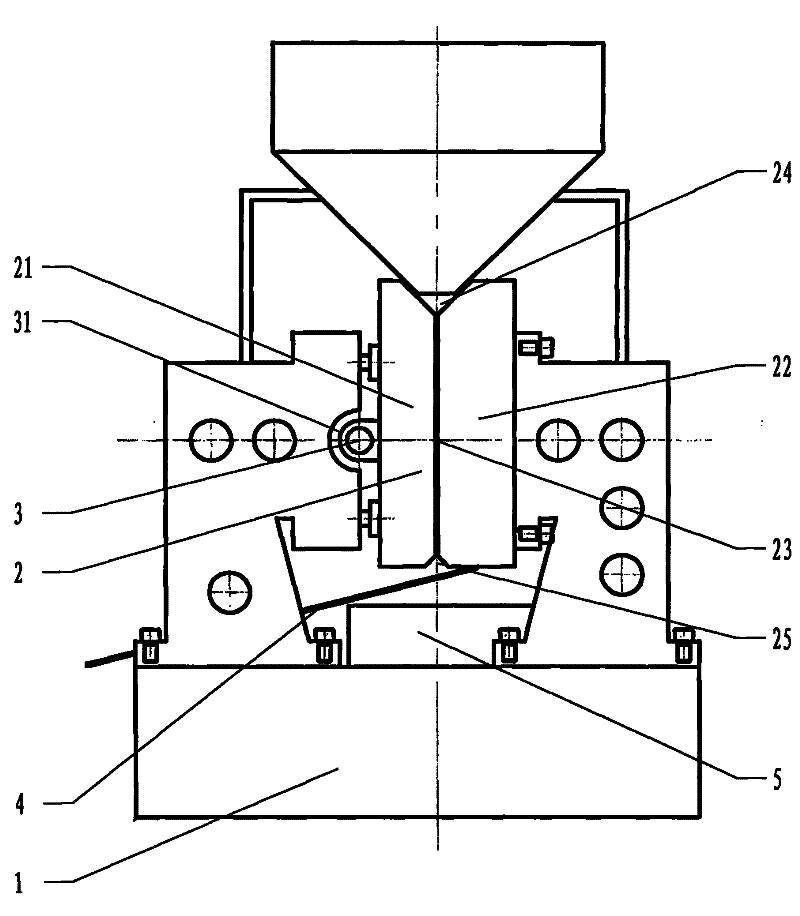

[0017] The present invention is a smelting tailings discrete metal gathering machine such as figure 1 As shown, it is mainly composed of a frame 1, a plate surface rubbing and grinding mechanism 2 installed on the frame 1, an electric control cabinet, and a driving component 3 electrically connected to the electric control cabinet. The above-mentioned drive components 3 can be hydraulic drive components, pneumatic drive components, or drive motors, these drive components 3 are controlled by the electric control cabinet, and the operator can control the work of the drive component 3 by setting the relevant parameters of the electric control cabinet state. The plate surface rubbing and extruding mechanism 2 is the core component of the present invention, and it mainly consists of a reciprocating rubbing plate 21 and an opposing rubbing support plate 22 . The reciprocating rubbing plate 21 and the opposing rubbing support plate 22 extend longitudinally along the frame 1 and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com