Air sealing method and device for washing machine

An air sealing device and air sealing technology, applied in the field of washing machines, can solve the problems of troublesome manufacturing, increased cost, and the sealing effect is not greatly improved, and achieve the effects of low production cost, simple structure and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

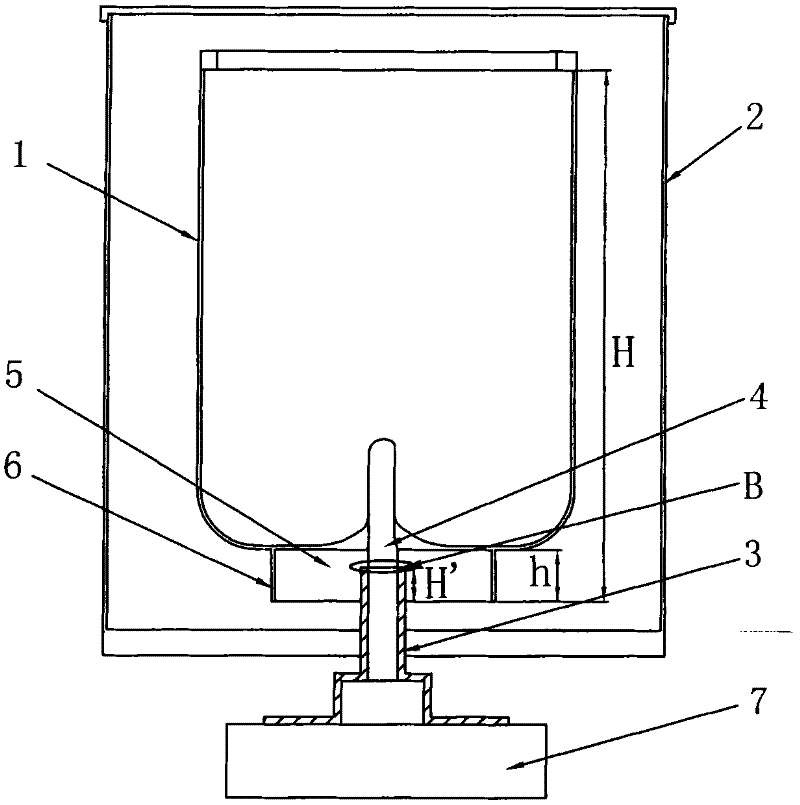

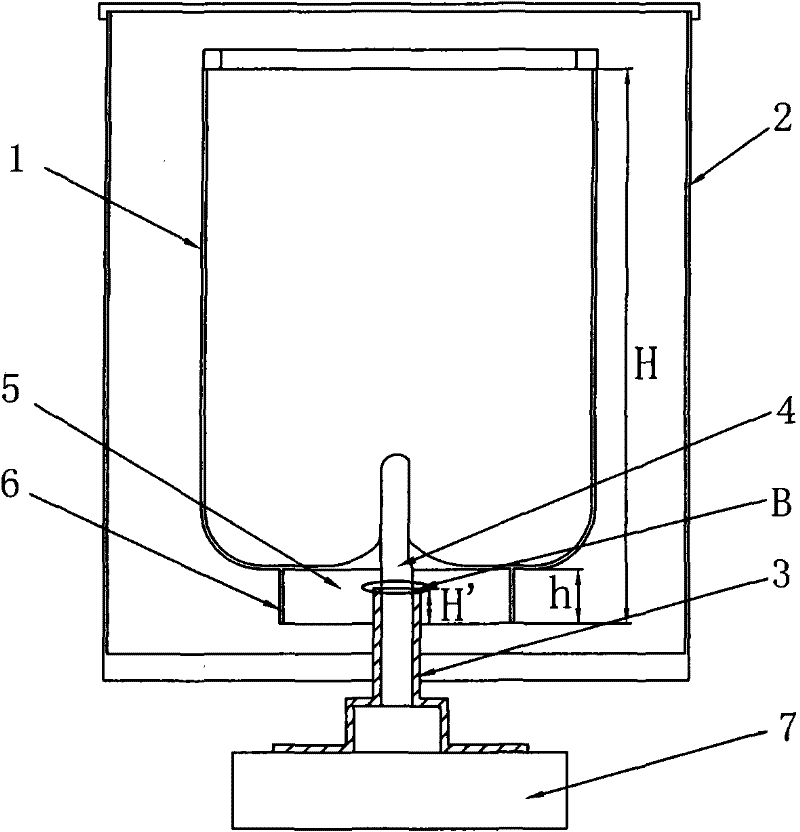

[0035] Such as figure 1 As shown, the air sealing device of the washing machine of the present invention, its basic principle is to utilize Boyer's theorem that "the pressure of the gas will increase with the shrinkage of the volume", and in combination with the principle of liquid circulation "the liquid is in a stationary object, The trend of its filling is an upward trend to maintain a horizontal state".

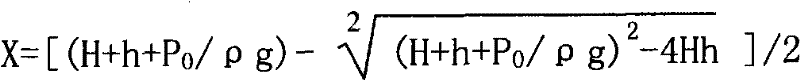

[0036] The sealing device is arranged between the bottom of the inner tub 1 and the bottom of the outer tub 2 of the pulsator washing machine, the motor shaft sleeve 3 extends between the bottom of the inner tub 1 of the pulsator washing machine and the bottom of the outer tub 2, and surrounds the motor shaft 4 and the motor shaft sleeve at the bottom of the inner tub 1 3. There is a chamber 5 with a circumferential closed bottom opening facing the bottom of the outer tub. The opening of the chamber 5 is facing the bottom of the outer tub 2. The upper end of the motor sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com