Reinforced concrete hollow floor

A technology for reinforced concrete and hollow-core slabs, which is applied to floors, buildings, building components, etc., and can solve problems such as poor impermeability of floors, loose connections, and poor integrity of floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

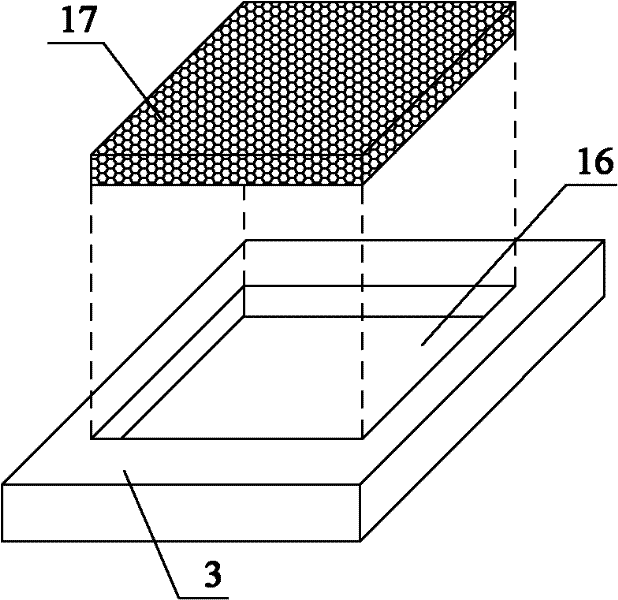

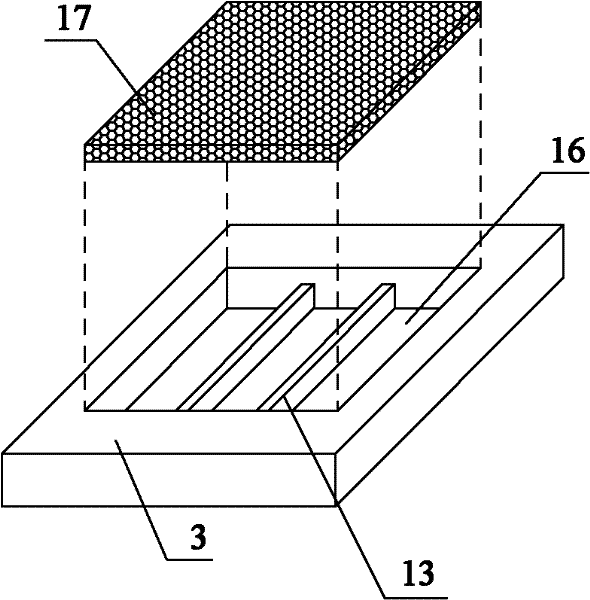

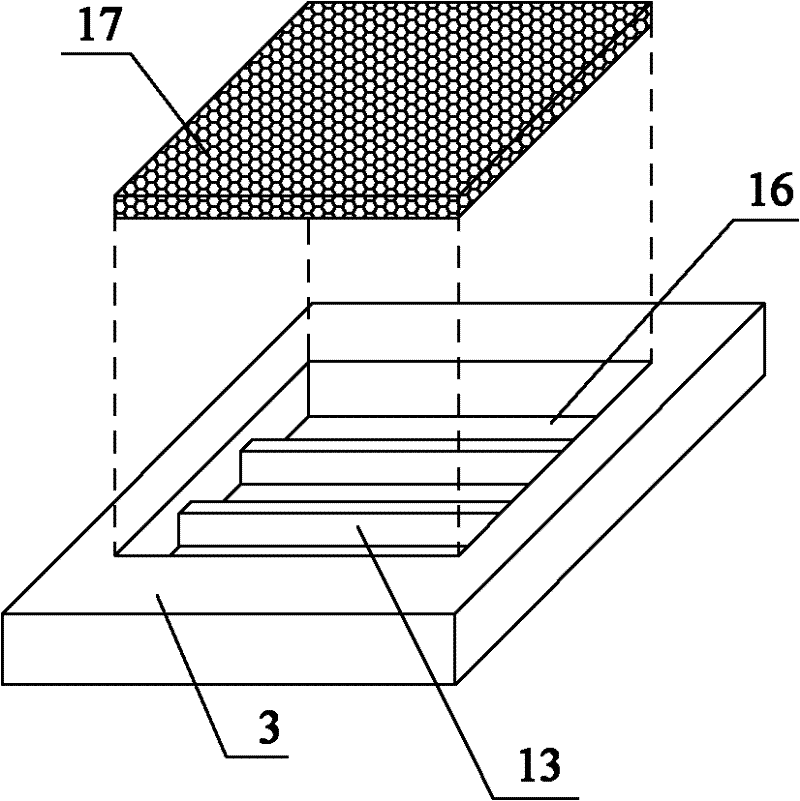

[0020] The invention is attached Figure 1-9 As shown, a reinforced concrete hollow floor slab includes cast-in-place dense ribs 1, prefabricated side walls 2, prefabricated bottom slab 3, and cast-in-place roof 4. The hollow floor slab consists of prefabricated side walls 2, prefabricated bottom The dense ribs 1 form a cavity 5, and the prefabricated floor 3 has a groove 16 on the top, and the groove 16 is filled with a polystyrene board 17 or lightweight concrete or lightweight materials. figure 1 It is a schematic diagram of filling the polystyrene board 17 in the groove 16 of the prefabricated base plate 3 .

[0021] There are longitudinal ribs or transverse ribs or both longitudinal ribs and transverse ribs in the groove 16 of the prefabricated floor 3, and polystyrene boards 17 or lightweight concrete or lightweight materials are covered on the ribs 13, so that the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com