Layered hoisting construction process for suspended steel structure

A construction technology and steel structure technology, which is applied in the direction of building structure, on-site preparation of building components, pillars, etc., can solve the problems of complex stress state, many components and structural units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

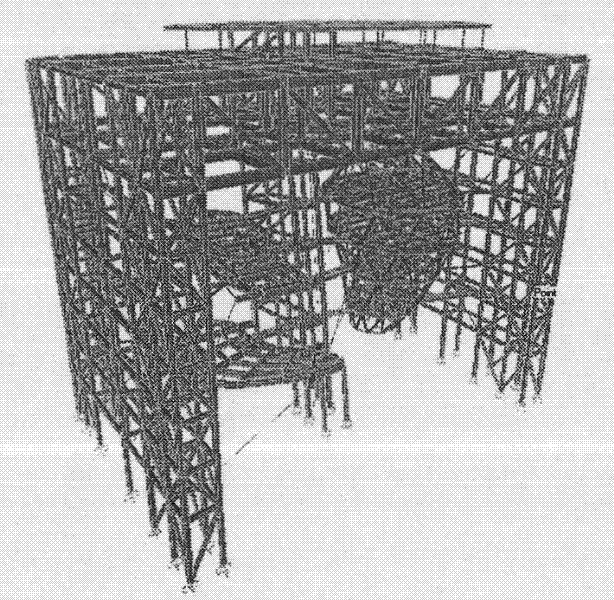

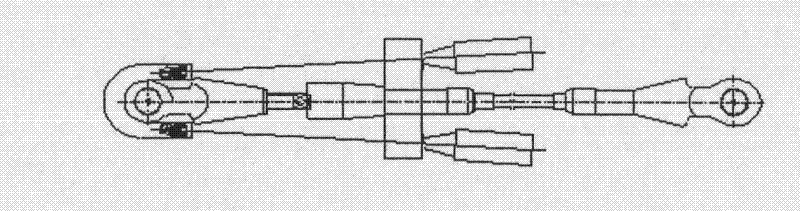

[0015] The figure includes a truss structure, a spherical pod structure in the space structure below the truss, and is characterized in that it consists of the following steps:

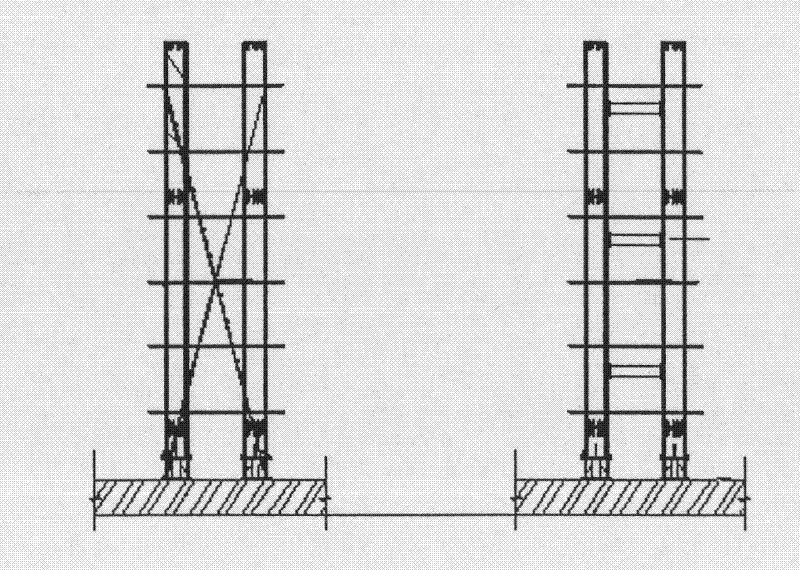

[0016] (1) Set up a high-altitude temporary support tire frame on the ground of the space structure under the truss,

[0017] (2) Carry out pod structure installation on the temporary support tire frame by high-altitude bulk method,

[0018] (3) Tensioning of high-strength suspension cables. After the pod structure is installed in place, the installation and tensioning of high-strength suspension cables are carried out. The entire tensioning process is divided into initial pre-tensioning before temporary support unloading, tensioning after structure installation and unloading, After the permanent load is in place, the construction is carried out in three stages of tensioning,

[0019] (4) The stabilizing cable pulls the pod structure downward.

[0020] It is characterized in that: the erection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com