Chain

A chain and end edge technology, applied in the field of low-friction chains, can solve the problems that the wedge film effect cannot be fully exerted and the sliding resistance increases, and achieve the effects of reducing the sliding contact area, reducing the resistance, and reducing the sliding contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

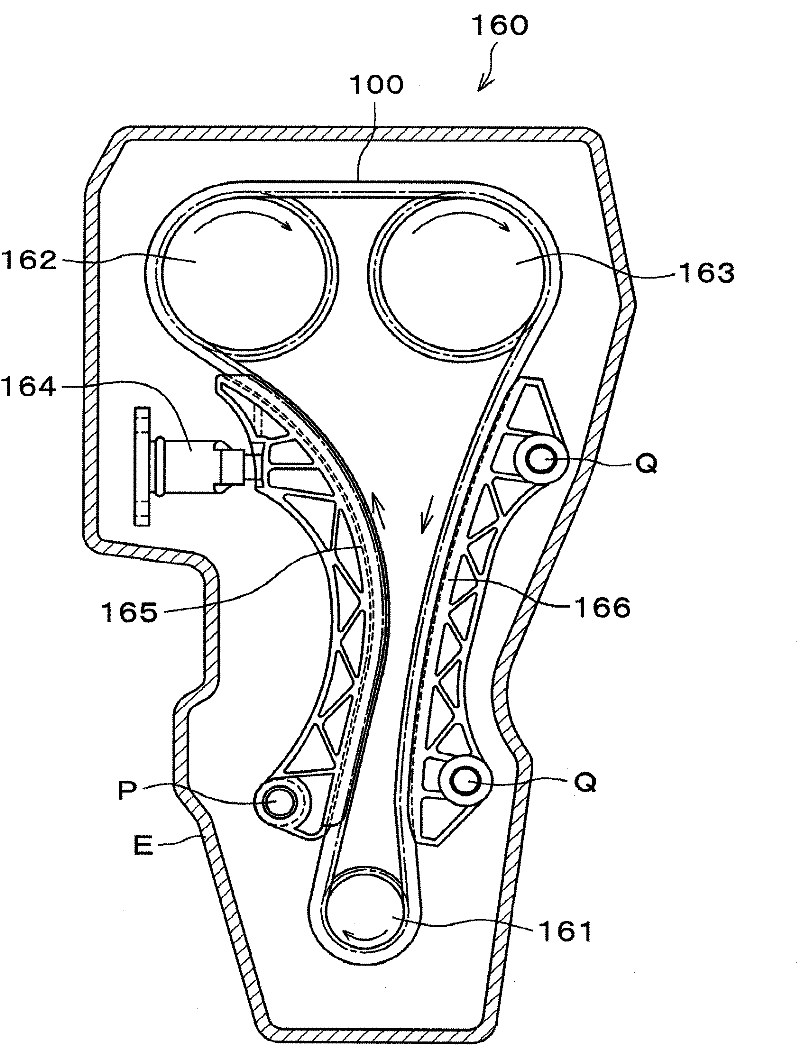

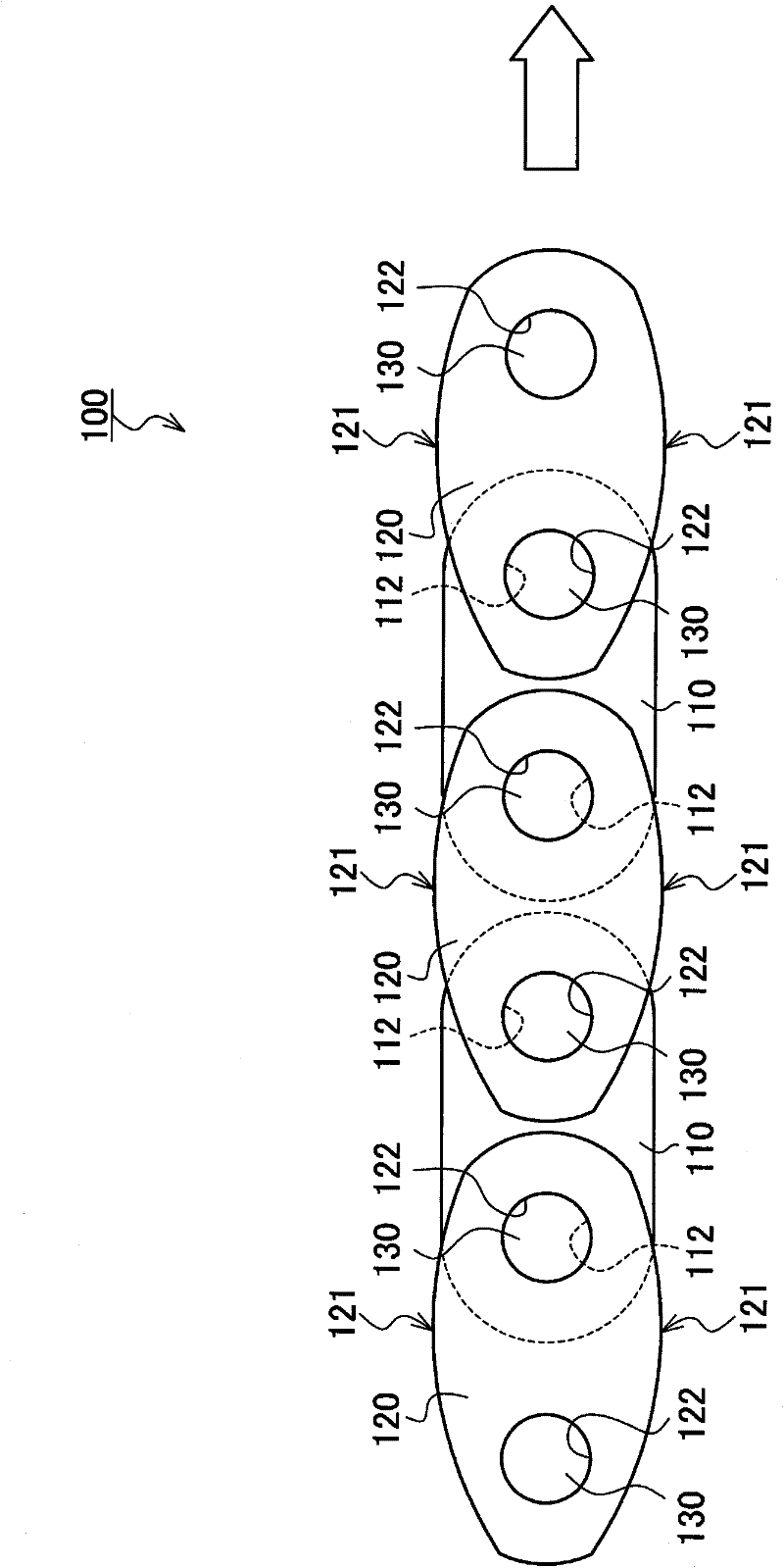

[0047] like figure 2 As shown, in the chain 100 according to the first embodiment of the present invention, a plurality of inner connecting plates 110 and outer connecting plates 120 formed with a pair of connecting holes 112 and 122 respectively are connected together by connecting pins 130 in a bendable manner .

[0048] However, as with the known chain 500 described above, it is of course possible to use a bendable sleeve chain in which the connecting pin 130 is slidably fitted in the connecting hole 112 of the inner connecting plate 110 through a fitting sleeve. A roller chain in which rollers are slidably fitted to the outer circumference of a sleeve.

[0049] The upper and lower end edges of the outer connecting plate 120 are convex end edges 121, which are formed into a convex shape composed of continuous curves, and are guided by sliding contact in the running direction of the chain; the upper and lower end edges of the inner connecting plate 110 are not guided by sl...

Embodiment 2

[0059] The chain of the second embodiment of the present invention will be described in detail below.

[0060] The chain of the second embodiment of the present invention has the same structure as the first embodiment, and the shape of its outer connecting plate is different.

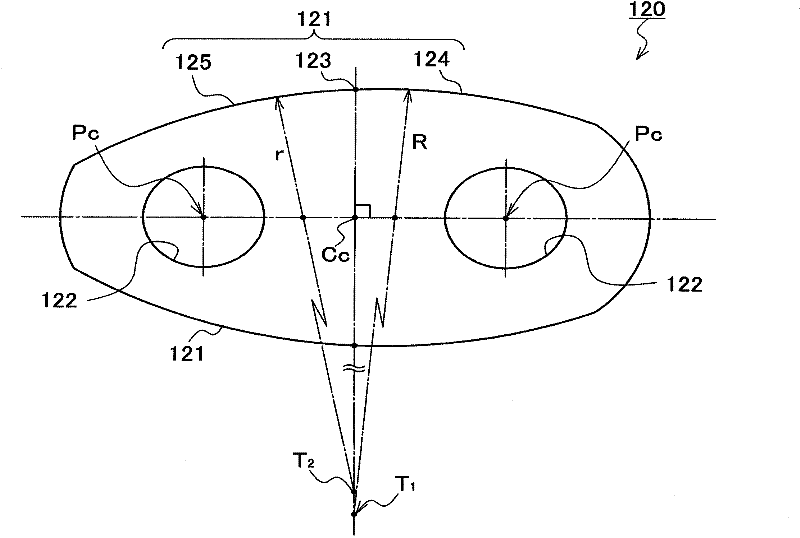

[0061] like Figure 5 As shown, in the outer connecting plate 220 of the chain according to the second embodiment of the present invention, the distance between the vertex 223 of the convex end edge 221 and the center Pc of the front and rear connecting holes 222 is equal, that is, the convex end edge The vertex 223 of the 221 is located on the vertical line of the middle point Cc of the connecting line between the front and rear connecting holes 222 .

[0062] In addition, on the curved convex edge 221 of the outer link plate 220 which is guided by sliding contact, from the vertex 223, the front edge 224 is located on the front side in the direction of travel of the chain, and the vicinity of the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com