Low-pressure micro-flow pressure reducing valve for space water sublimator

A sublimator, micro-flow technology, applied in valve details, valve devices, safety valves, etc., can solve the problems of high pressure control accuracy, low pressure adjustment range, and extremely small flow requirements, achieving compact size and reducing slippage. Contact area, the effect of alleviating extreme low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

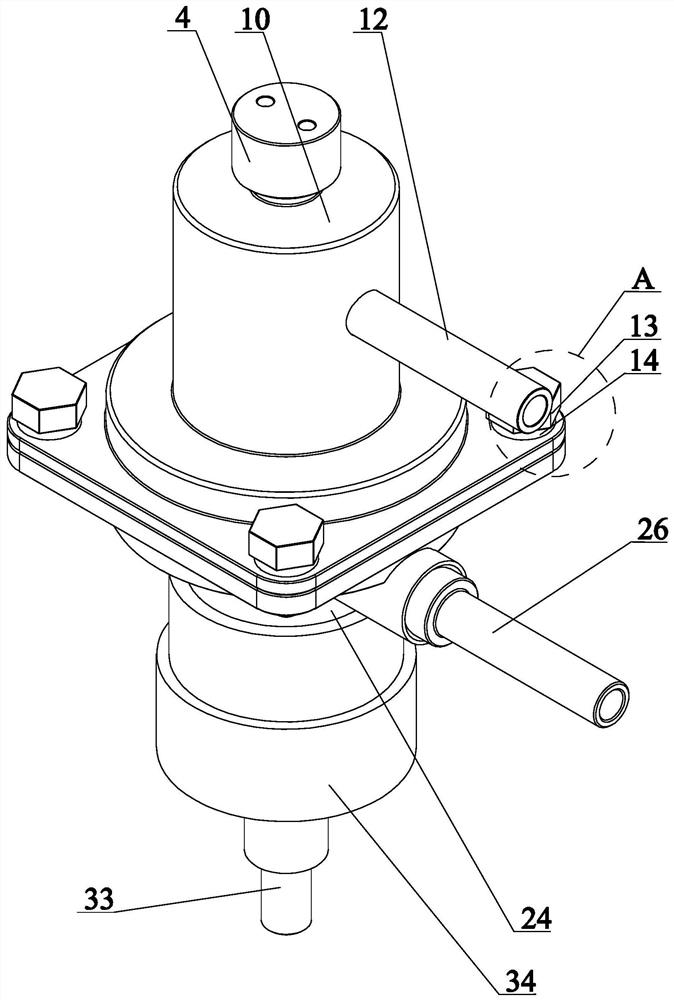

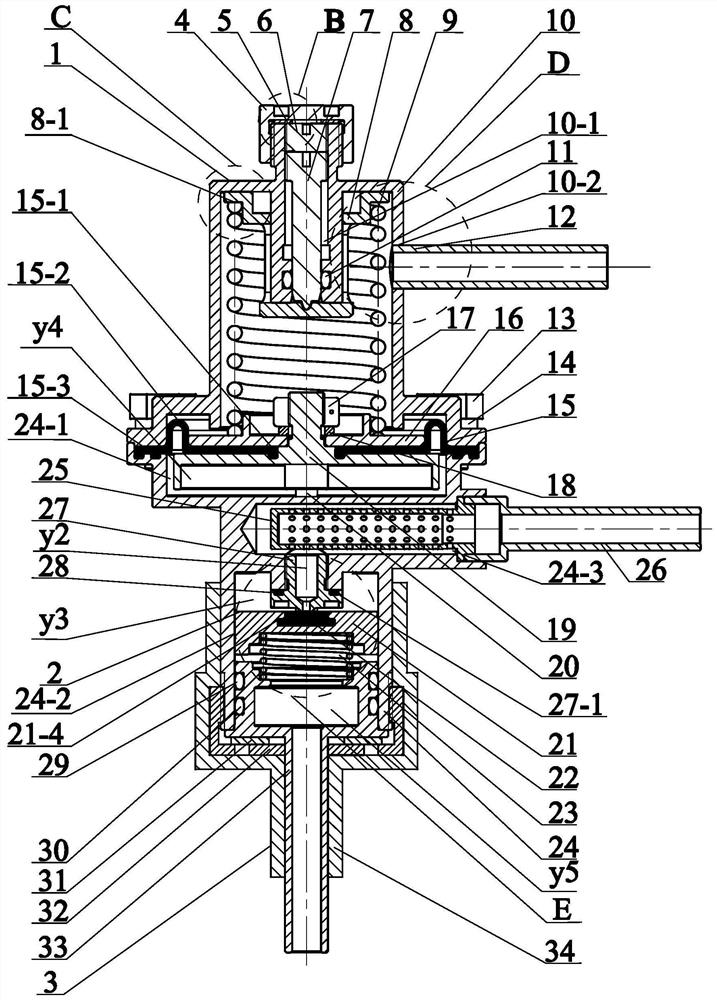

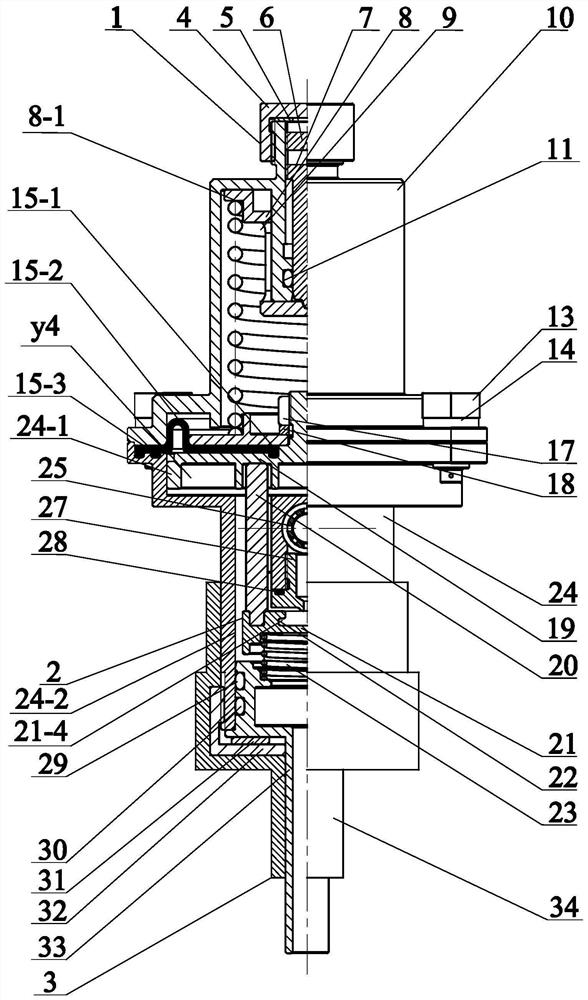

[0031] Specific implementation mode one: as Figure 1-Figure 13 As shown, this embodiment discloses a low-pressure micro-flow pressure reducing valve for a space water sublimator, including an upper housing assembly 1, a diaphragm valve core assembly 2 and a lower housing assembly 3;

[0032] The upper housing assembly 1 includes a pressure regulating end cover 4, a pressure regulating pipe locker 6, a pressure regulating rod 7, a pressure regulating plate 8, a pressure regulating spring 9, an upper casing 10 and a ventilation pipe 12;

[0033] The diaphragm spool assembly 2 includes a diaphragm assembly and a spool assembly, and the diaphragm assembly includes a diaphragm 15, a diaphragm upper stopper 16, a nut 17, a diaphragm guide seat 19 and two push rods 20; The valve core assembly includes a valve core 21, a valve port matching body 22 and a return spring 23;

[0034] The lower casing assembly 3 includes a lower casing 24, a filter 25, a water inlet pipe 26, a nozzle 27...

specific Embodiment approach 2

[0039] Specific implementation mode two: as figure 2 , image 3 As shown, this embodiment is a further description of specific embodiment 1. The middle part of the top wall of the upper casing 10 is respectively provided with a downwardly extending boss 1 and an upwardly extending boss 2, and the boss 1 and The middle part of the boss two is provided with a connected upper center hole 10-1, and the pressure regulating rod 7 is arranged in the upper center hole 10-1 of the upper casing 10 and the two are screwed (the upper center hole of the upper casing 10 The upper end of the inner wall of 10-1 is provided with internal threads, and the outer wall of the upper end of the pressure regulating rod 7 is provided with external threads); the pressure regulating pipe locker 6 is arranged in the upper center hole 10-1 of the upper casing 10 and both Threaded connection (the outer wall of the regulator tube locker 6 is provided with an external thread, and the regulator tube locker ...

specific Embodiment approach 3

[0040] Specific implementation mode three: as figure 2 , image 3 and Figure 11 As shown, this embodiment is a further description of the second specific embodiment. The central hole of the pressure regulating plate 8 is fixedly set on the upper end of the outer side of the boss one, and the outer periphery of the pressure regulating plate 8 is provided with an outer step 8-1 , the upper end of the pressure regulating spring 9 leans against the end face of the outer step 8-1 of the pressure regulating plate 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com