Full-sealed side wire outlet type amorphous alloy transformer

An amorphous alloy and transformer technology, which is applied in the field of fully sealed side-outlet amorphous alloy transformers, can solve problems affecting transformer performance, power sector losses, safety hazards, etc., so as to improve the safety of use, prolong the service life, and meet the energy saving requirements. Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

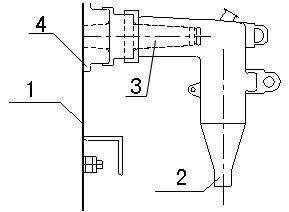

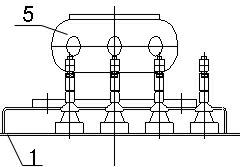

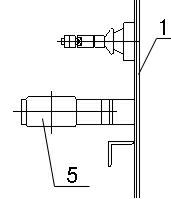

[0015] Fully sealed side outlet type amorphous alloy transformer, including the following technical features: ①Transformer high-voltage side bushings are changed to American-style box transformer special bushings, and elbow-shaped cable joints 2, single-pass bushings 3, and bushing seats 4 are used to match and connect in sequence The structural form ensures that all joints of high-voltage cables do not leak out, improves the safety of high-voltage bushings of transformers, and makes it easier to repair and replace high-voltage wiring and bushings of transformers; Installed current transformer 5, the current transformer can convert the current flowing through the low-voltage cable to the control room of the power department, and convert it into direct reading of low-voltage power consumption data, ensuring the accuracy of transformer power consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com