Rolling bearing unit with combination seal ring

A rolling bearing and combined sealing technology, which is applied in rolling contact bearings, bearing components, bearings with rotating motion, etc., can solve problems such as easy intrusion and grease leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Means for Carrying Out the Invention

[0055] [First example of embodiment]

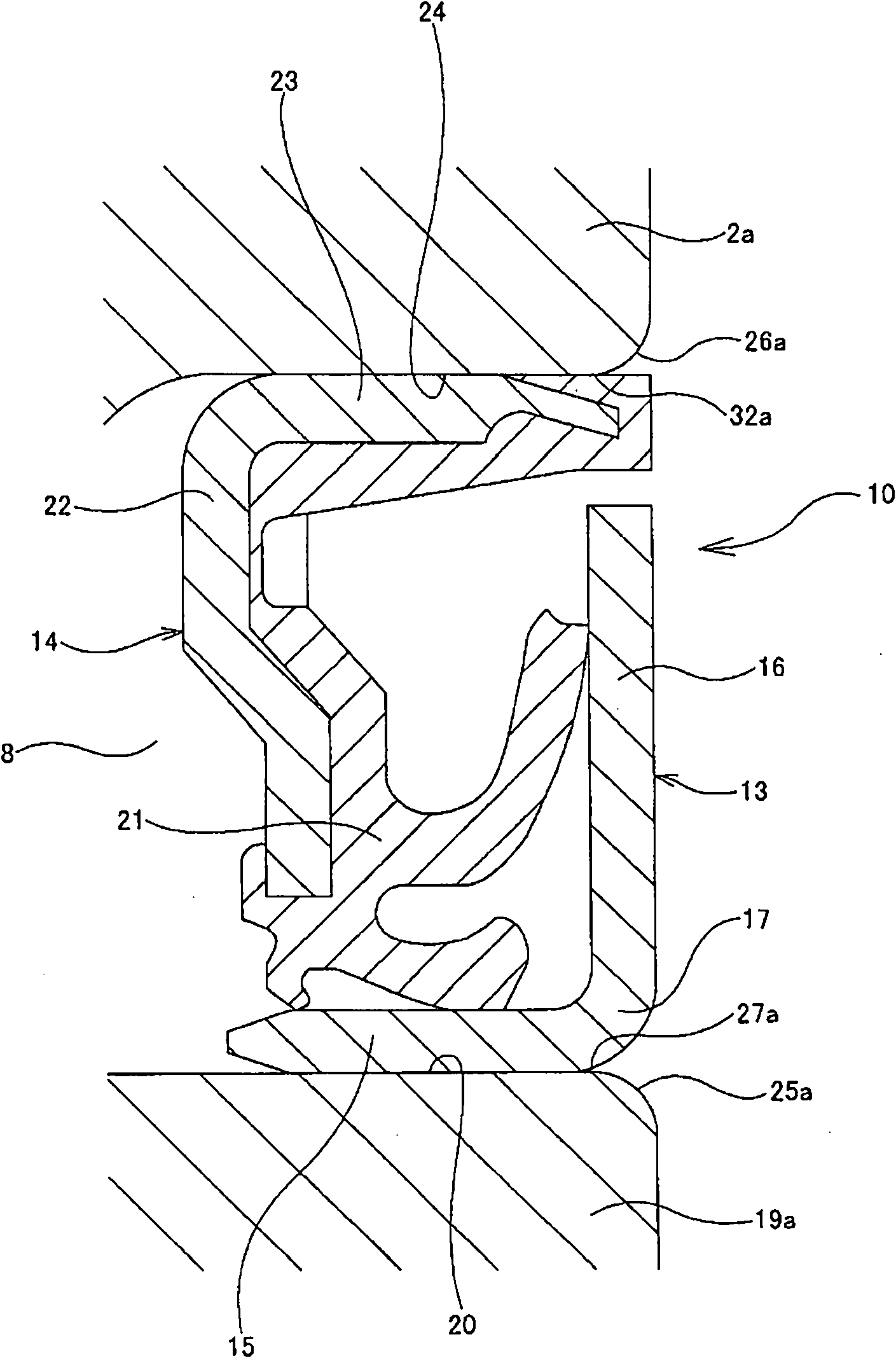

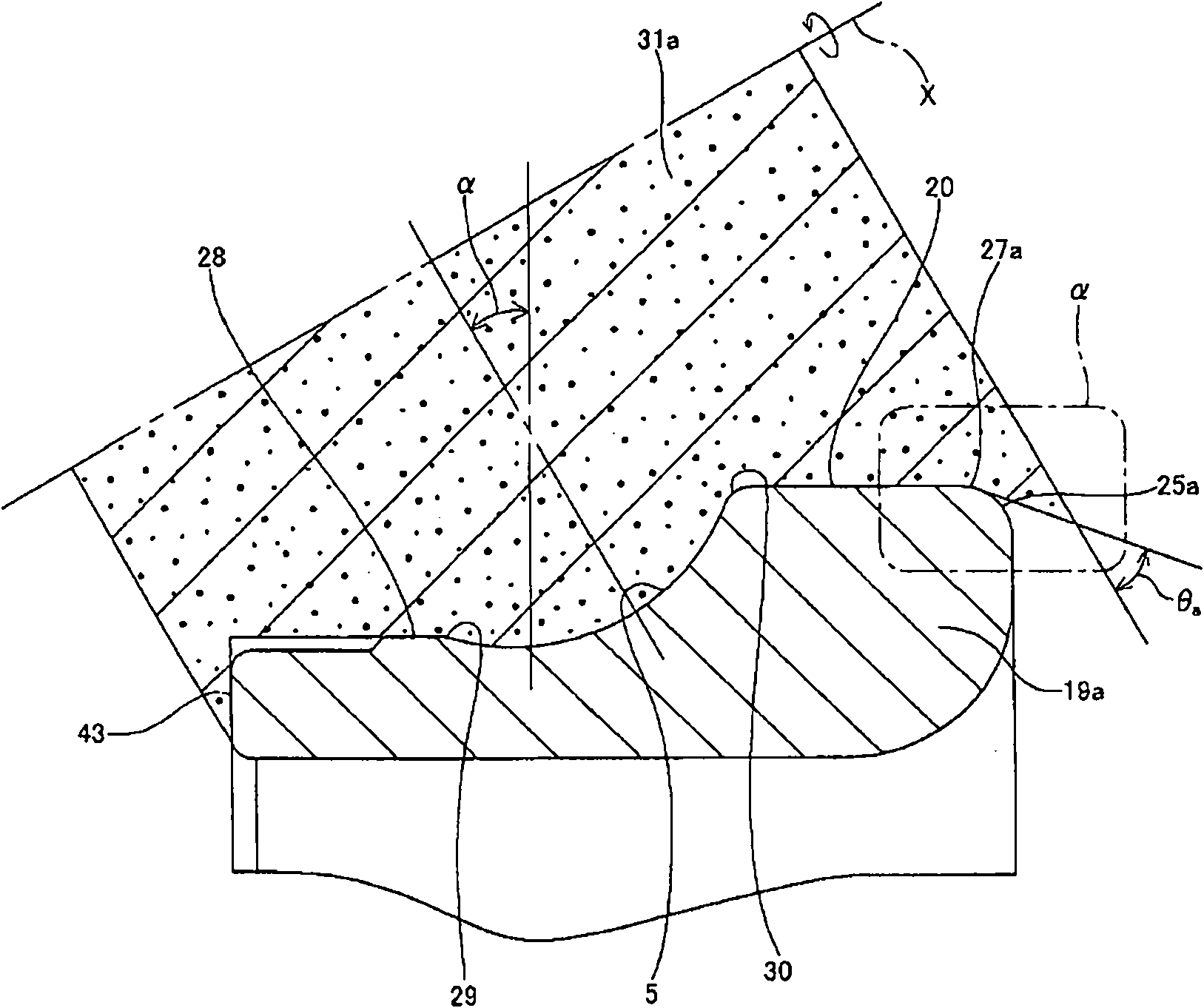

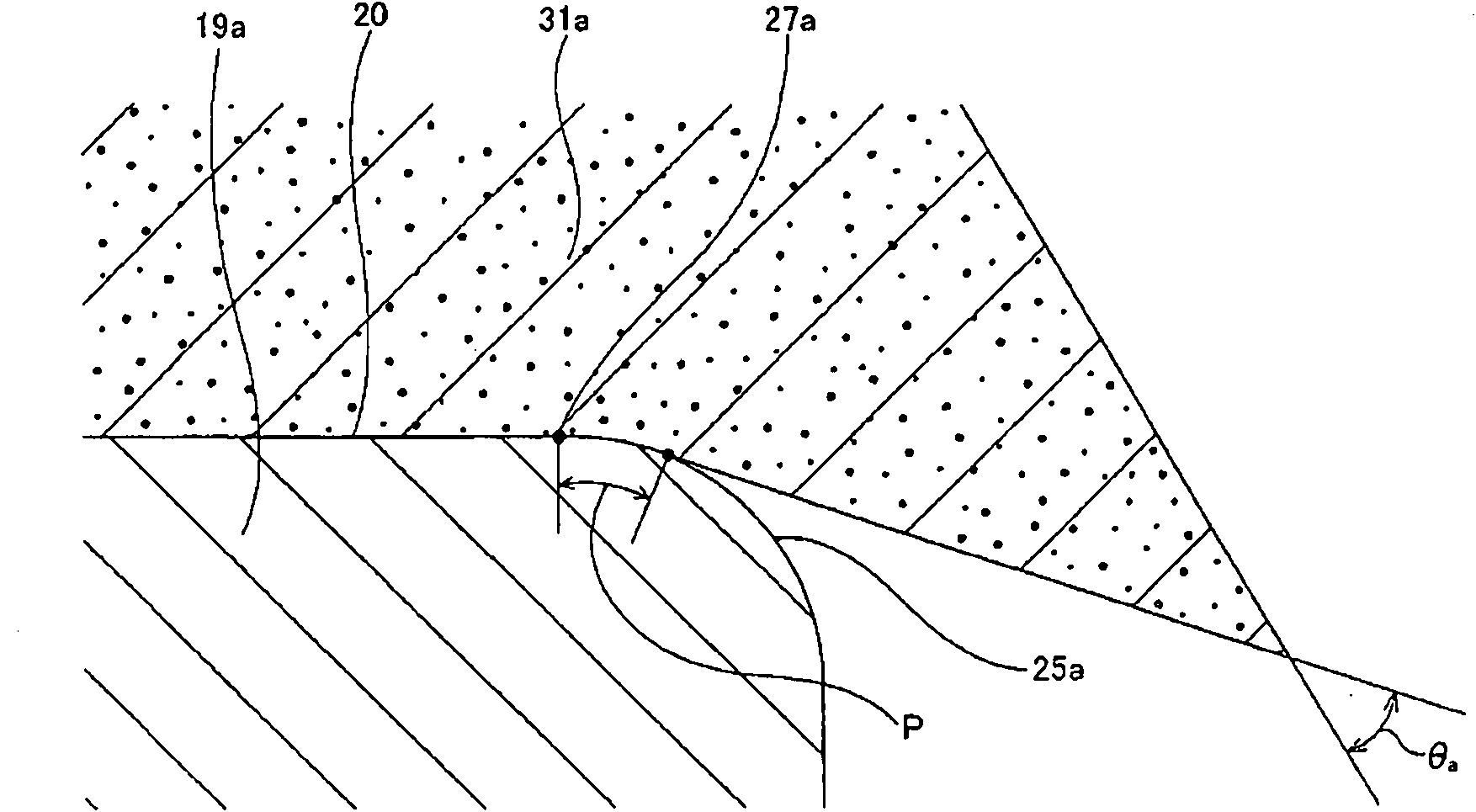

[0056] Figure 1~5 The first example of the embodiment of the present invention is shown. In addition, this example is characterized in that the shape of the axially inner end outer peripheral surface of the inner ring 19a, the shape of the axially inner end inner peripheral surface of the outer ring 2a, and their processing methods were studied. The structure and function of other parts are different from the above Figures 15-16 The situation of the conventional structure shown is the same, therefore, overlapping illustrations and descriptions will be omitted or simplified, and the following description will focus on the characteristic parts of this example.

[0057]In the case of this example, the part of the cylindrical fitting surface 20 for oil deflector existing in the axial inner end of the outer peripheral surface of the inner ring 19a and the cross-sectional arc existing in the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com