High-speed precision cutting machine

A cutting machine and precise technology, applied in conveyors, metal processing, transportation and packaging, etc., can solve problems such as inability to use flexible materials to cut, unreasonable structural design, inability to cut flexible materials, etc., to improve cutting efficiency, Compact structure and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment provides detailed implementation and specific operation procedures, but the protection scope of the present invention is not limited to the following embodiments.

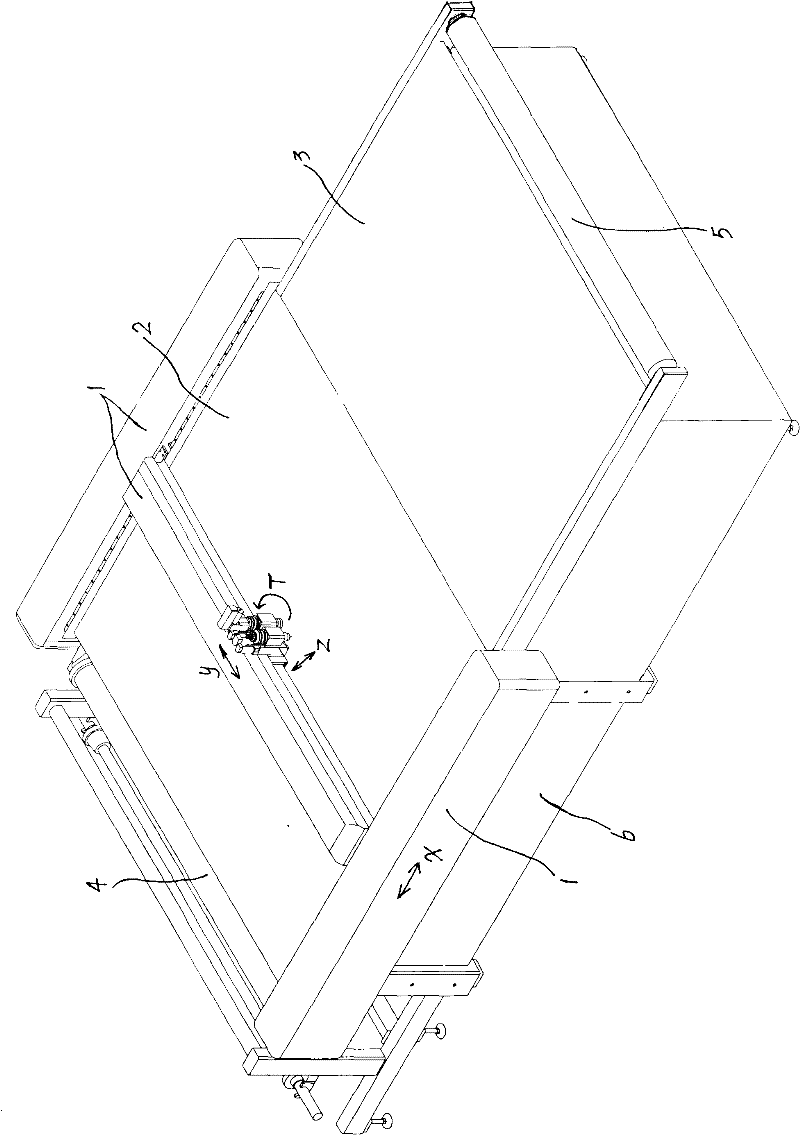

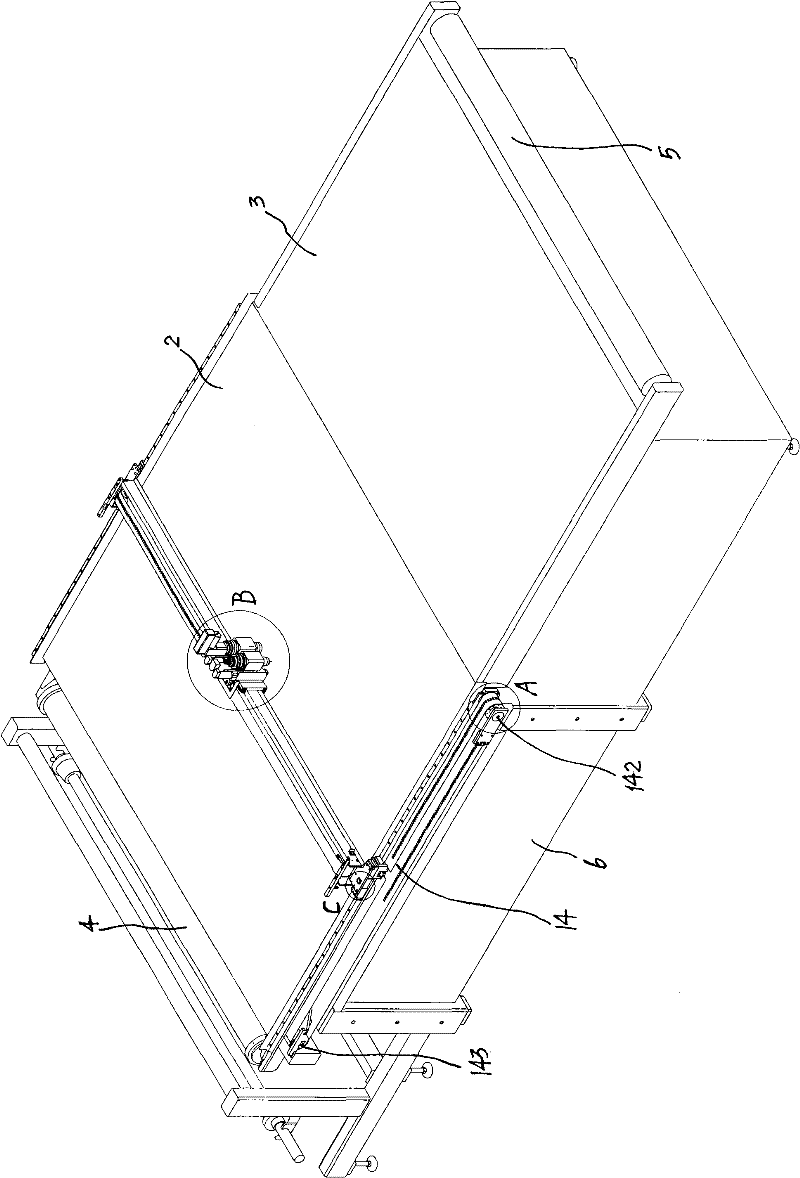

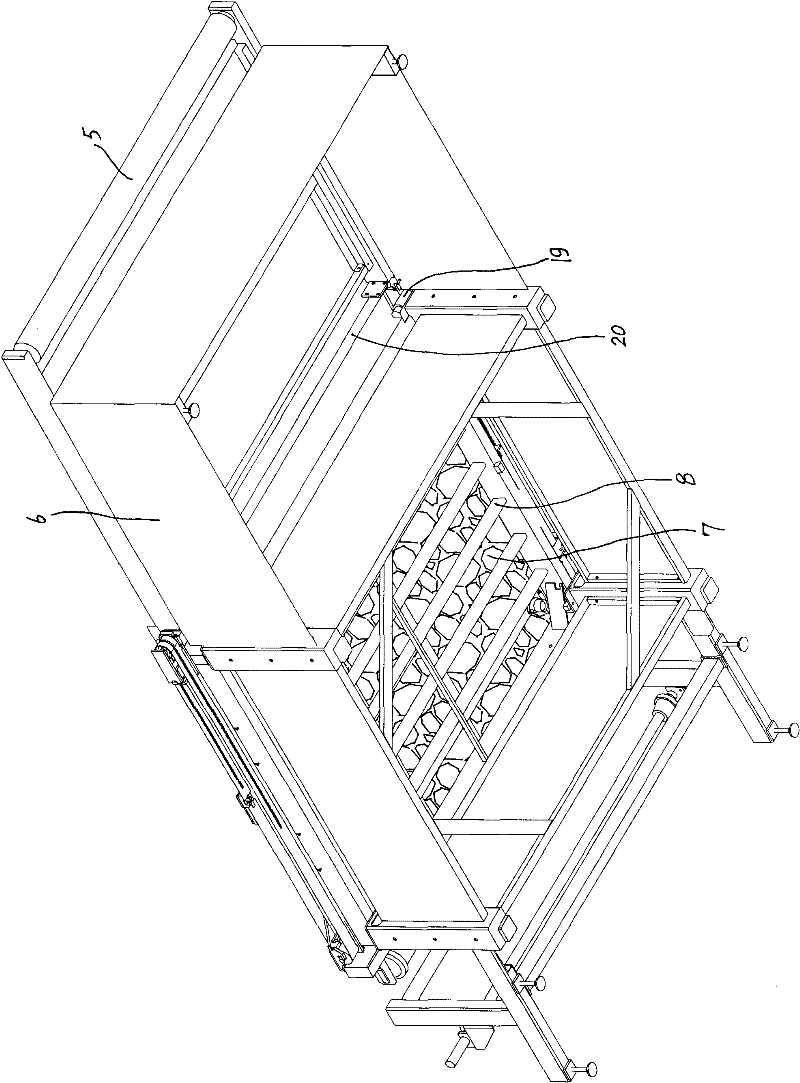

[0044] See Figure 1~Figure 20 , The present invention includes protective cover 1, work surface 2, auxiliary work surface 3, feeding device 4, receiving device 5, frame 6, vacuum chamber 7, vacuum chamber frame 8 and tensioning mechanism 9; these structures and connections are all compatible with The prior art is the same or equivalent, and those skilled in the art are familiar with it, and will not be detailed.

[0045] The invention also includes a machine head 11, a beam 12, a material pressing mechanism 13, a conveying mechanism 14, a high-frequency vibration device 15, a linear slider 16, a one-way floating device 17 and a tool height fine-tuning mechanism 18; the machine he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com