Method for producing synchronous grain raised wood floor

A production method and technology of wood flooring, applied in wood processing equipment, crafts for producing decorative surface effects, decorative art, etc., can solve the problems of large consumption, high price, low output, etc., achieve efficient utilization and reduce felling , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

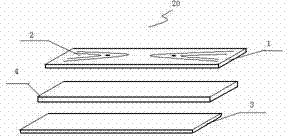

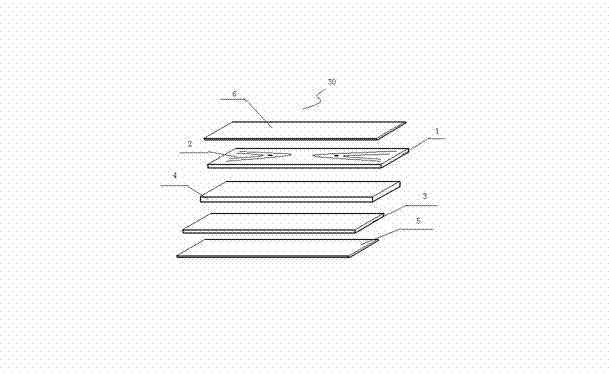

Image

Examples

Embodiment 1

[0030] After sanding and polishing the 15mm thick poplar plywood, use a four-color printing machine to directly print the selected teak pattern on the surface with a certain permeability ink, and then align the embossed pattern on the molded steel plate with the printed pattern Pressurize at 18MPa, and at the same time heat the lower steel plate of the poplar plywood to 245°C, heat the embossed molded steel plate to 230°C, keep it for 25 seconds, release the pressure and cool for a week, and use a polishing machine to gently polish to remove the fine edges and corners caused by embossed molding Finally, according to the paint process, the surface of the board is treated to obtain a full poplar antique wood floor with a synchronous embossed effect.

[0031]

Embodiment 2

[0033] After sanding and polishing the 12mm-thick particleboard with 1.5mm-thick poplar veneer pasted on both sides, use a four-color printing machine to directly print the selected Huanghuai wood pattern on the surface with a certain permeability ink, and then print it on the molded steel plate. Align the embossed pattern with the printed pattern and pressurize at 22MPa. At the same time, heat the steel plate under the particle board to 245°C, heat the embossed molded steel plate to 230°C, keep it for 25 seconds, release the pressure and cool for a week, and use a polishing machine to gently polish and remove the embossed molded The fine edges, corners and burrs are finally treated according to the paint process to obtain the particle board-poplar antique wood floor with synchronous embossed effect.

[0034]

Embodiment 3

[0036] After sanding and polishing the 12mm thick high-density fiberboard with 1.5mm thick poplar veneer pasted on both sides, use a four-color printing machine to directly print the selected walnut pattern on the surface with a certain permeability ink, and then The embossed pattern on the molded steel plate is aligned with the printed pattern and pressurized at 25MPa. At the same time, the steel plate under the particle board is heated to 180°C, and the embossed molded steel plate is heated to 190°C for 45 seconds. The pressure is released and cooled for a week, and lightly polished with a polishing machine. Remove the fine edges and burrs caused by embossed molding, and finally treat the surface of the board according to the painting process to obtain the high-density fiberboard-poplar antique wood floor with synchronous embossed effect.

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com