Green brick forming machine

A technology for forming machines and bricks, applied in the direction of ceramic extrusion dies, etc., can solve the problems of wasting waiting time, long time spent, affecting the productivity of brick blanks, etc., and achieve the effect of improving productivity and reducing time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

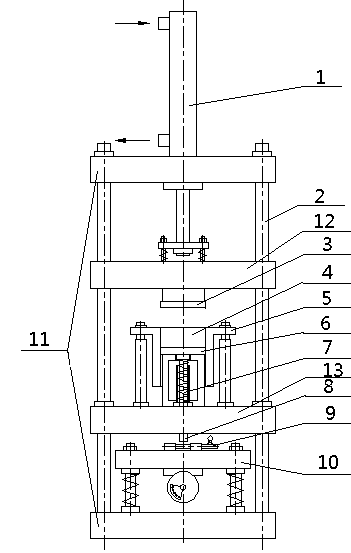

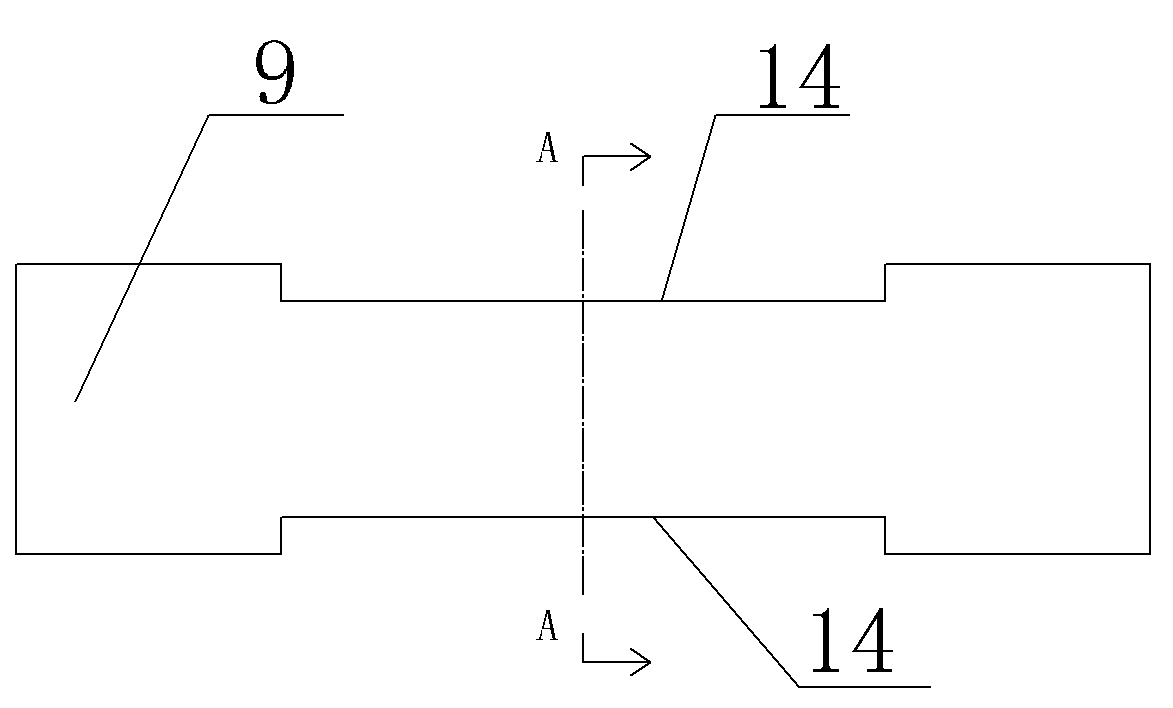

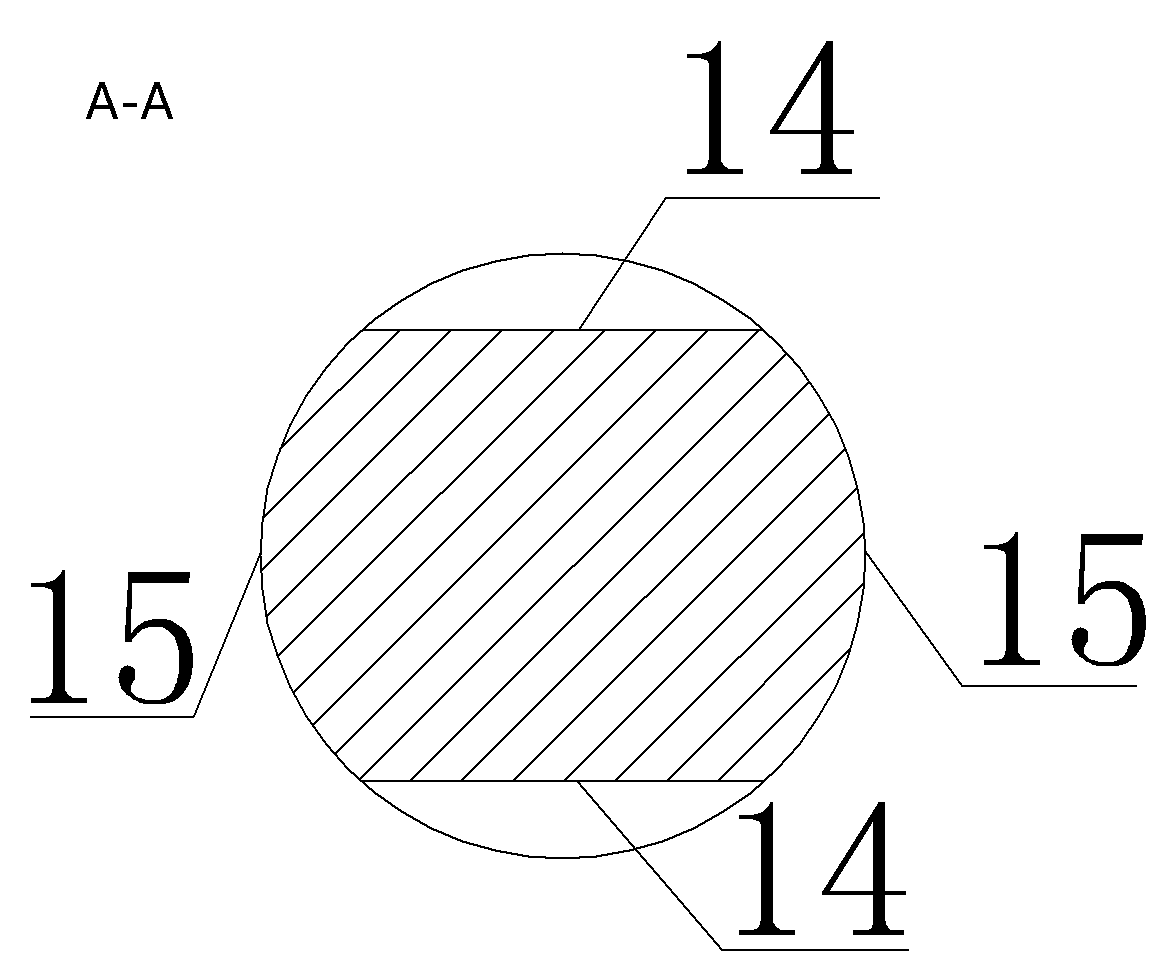

[0017] Example Figure 1~3 Shown: the adobe forming machine includes a frame 11, the frame 11 is provided with four guide columns 2 along the vertical direction, and the upper mold frame 12 and the lower mold frame 12 are arranged side by side on the guide columns 2 along the up and down direction. Formwork 13 and vibrating table 10, described upper formwork 12, lower formwork 13 and vibrating table 10 are all arranged along the horizontal direction, and described upper formwork 12 is slidably assembled on On the guide column 2, the vibrating table is floated on the frame 11 through a spring and a guide post, and the vibrating table 10 provides vibration force through a vibrating motor arranged below it. The upper mold frame 12 is provided with an upper die head 3 for extruding the material to be formed; the lower mold frame 13 is provided with a mold 5 for brick forming, and the mold 5 includes a mold bottom plate 6, The mold 5 is moved and assembled on the lower mold base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com