Printing stencil positioning arrangement for screen printing unit

A positioning device and screen printing technology, applied in screen printing, screen printing machines, printing, etc., can solve problems such as reducing efficiency, and achieve the effect of avoiding undesired effects, high-precision positioning, and realizing positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

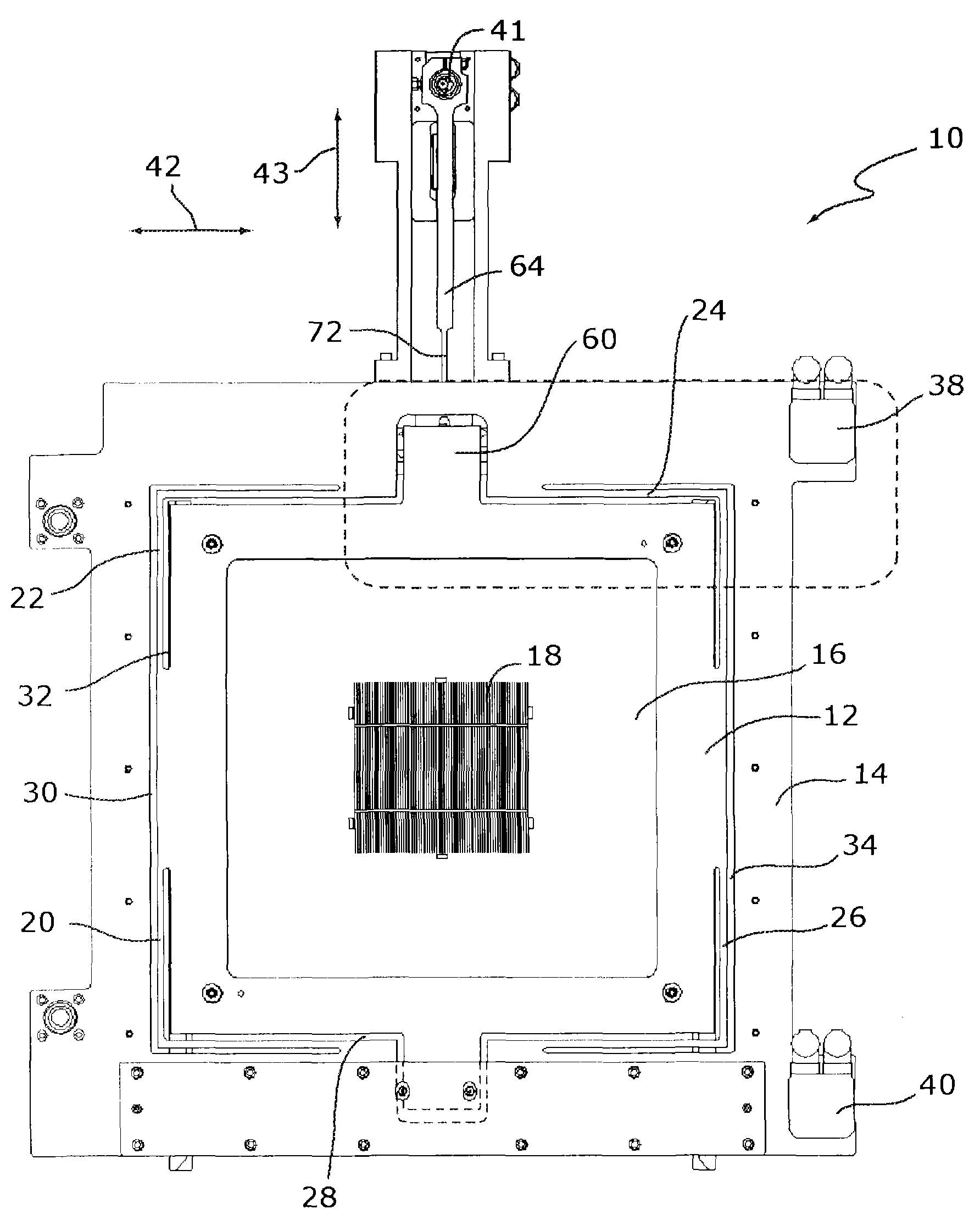

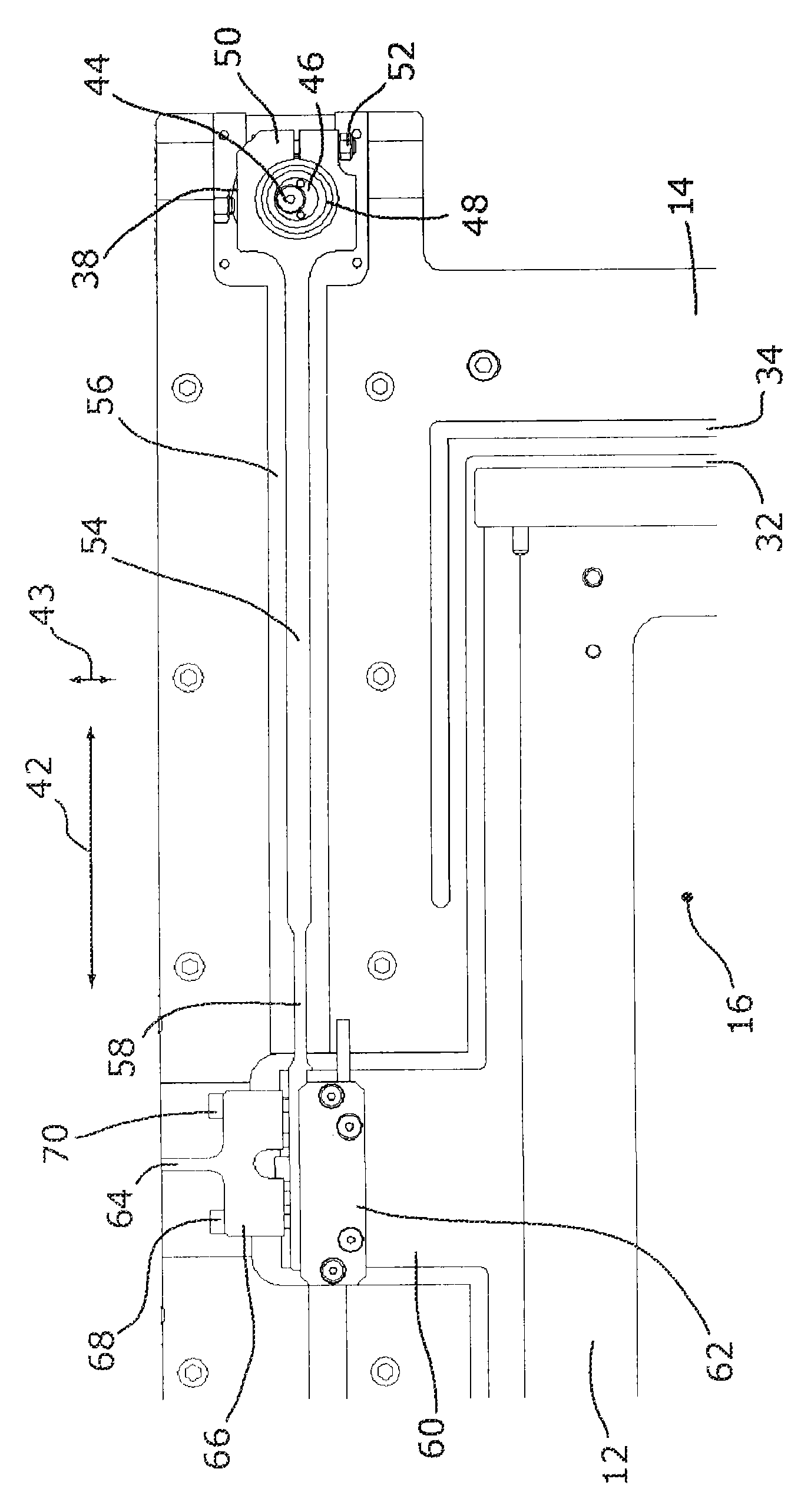

[0024] figure 1A screen positioning device 10 is shown comprising a movable part 12 and a fixed position part 14 . A screen frame is arranged on the movable part 12 for holding a screen 16 with a stencil or printed structure 18 . The movable part 12 is connected to the fixed part 14 by means of flexible parts 20 , 22 , 24 , 26 designed as webs. In this case, the flexible part is produced by introducing openings 28 , 30 , 32 , 34 into metal sheets, in particular aluminum or steel sheets. This measure subdivides the metal plate into a stationary part 14 and a movable part 12 , wherein the parts 12 , 14 are connected by flexible parts 20 , 22 , 24 , 26 . The screen positioning device 10 is thus designed in one piece, ie the position-fixed part 14 and the movable part 12 are connected to one another in a materially bonded manner and formed in one piece. That is, the flexible parts 20 , 22 , 24 , 26 are defined by the material remaining between the movable part 12 and the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com