Environmentally-friendly plastic table printing black ink and preparation method thereof

A surface printing and plastic technology, applied in the field of printing ink and its preparation, can solve the problems affecting the health of ink printing operators, destroying the atmosphere, polluting the air, etc., to achieve the effects of eliminating damage, saving paper and energy, and benefiting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] One, be 95% ethanol with concentration and 99% ethyl acetate as solvent, dissolve liquid modified polyamide resin and make 25% alcohol-soluble polyamide resin liquid, wherein the weight percent of ethanol is 50%, ethyl acetate The weight percentage of the ester is 25%, and the weight percentage of the modified polyamide resin solution is 25%.

[0024] 95% ethanol and 99% ethyl acetate are used as solvents to dissolve liquid nitrocellulose resin to make 20% nitrocellulose resin liquid, wherein the weight percentage of ethanol is 45%, and the weight percentage of ethyl acetate is 35%. %, the weight percentage of the modified polyamide resin solid is 20%.

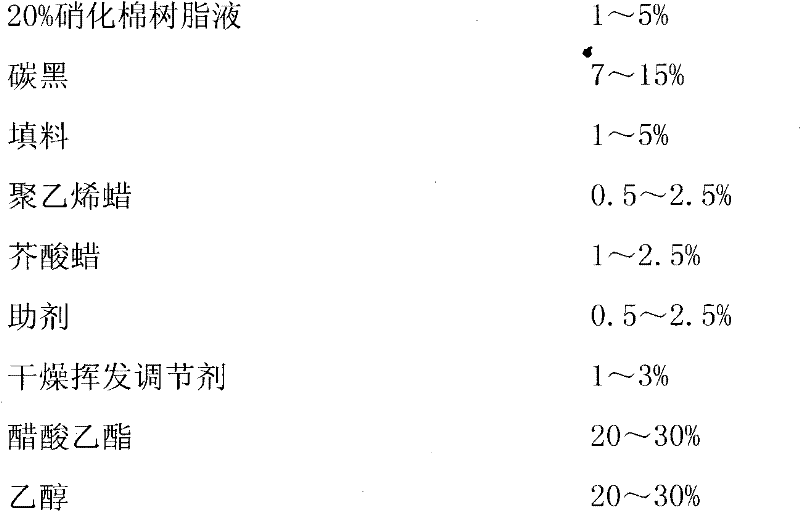

[0025] 2. The specific components of environmentally friendly surface printing plastic black ink are as follows:

[0026]

[0027]

[0028] 3. The preparation method of the above environmental protection surface printing plastic black ink is:

[0029] 1) Disperse raw materials once: 60% of raw material 25% alcoh...

Embodiment 2

[0033] One, be 95% ethanol with concentration and 99% ethyl acetate as solvent, dissolve liquid modified polyamide resin and make 25% alcohol-soluble polyamide resin liquid, wherein the weight percent of ethanol is 45%, ethyl acetate The weight percentage of the ester is 30%, and the weight percentage of the modified polyamide resin solution is 25%.

[0034] 95% ethanol and 99% ethyl acetate are used as solvents to dissolve liquid nitrocellulose resin to make 20% nitrocellulose resin liquid, wherein the weight percentage of ethanol is 40%, and the weight percentage of ethyl acetate is 40%. %, the weight percentage of the modified polyamide resin solid is 20%.

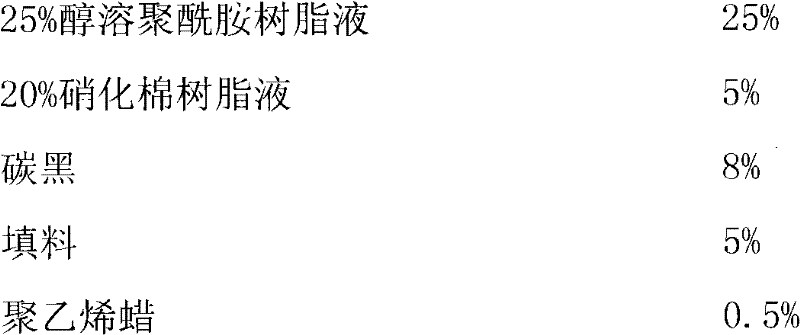

[0035] 2. The specific components of environmentally friendly surface printing plastic black ink are as follows:

[0036]

[0037]

[0038] 3. The preparation method of the above environmental protection surface printing plastic black ink is:

[0039] 1) primary dispersion raw material: 55% of raw material 25% a...

Embodiment 3

[0043] One, be 95% ethanol with concentration and 99% ethyl acetate as solvent, dissolve liquid modified polyamide resin and make 25% alcohol-soluble polyamide resin liquid, wherein the weight percent of ethanol is 55%, ethyl acetate The weight percentage of the ester is 20%, and the weight percentage of the modified polyamide resin solution is 25%.

[0044] 95% ethanol and 99% ethyl acetate are used as solvents to dissolve liquid nitrocellulose resin to make 20% nitrocellulose resin liquid, wherein the weight percentage of ethanol is 50%, and the weight percentage of ethyl acetate is 30%. %, the weight percentage of the modified polyamide resin solid is 20%.

[0045] 2. The specific components of environmentally friendly surface printing plastic black ink are as follows:

[0046]

[0047]

[0048] 3. The preparation method of the above environmental protection surface printing plastic black ink is:

[0049] 1) primary dispersion raw material: 50% of 25% alcohol-soluble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com