Movable pushing device for sliding launch of large jacket

A jacket and movable roof technology, which is applied in the field of offshore oil engineering, can solve the problems of uneven force on large jackets, difficult control of thrust, and influence on project quality and progress. Small, the effect of increasing the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

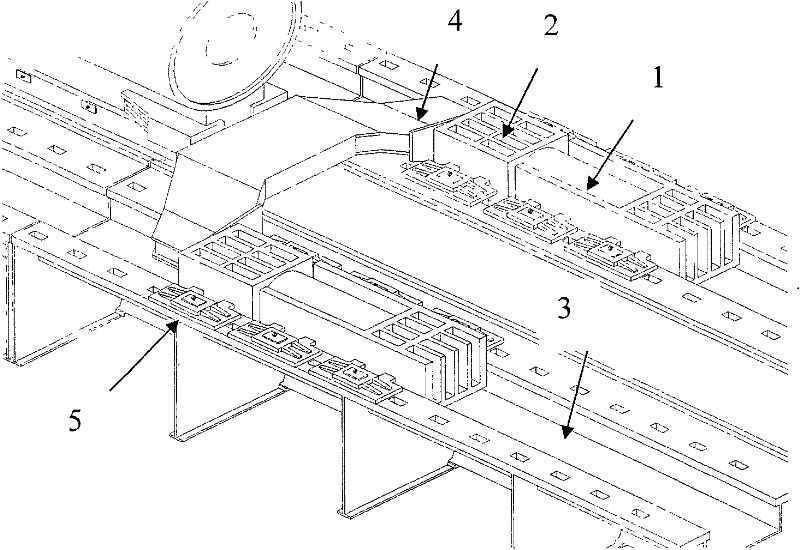

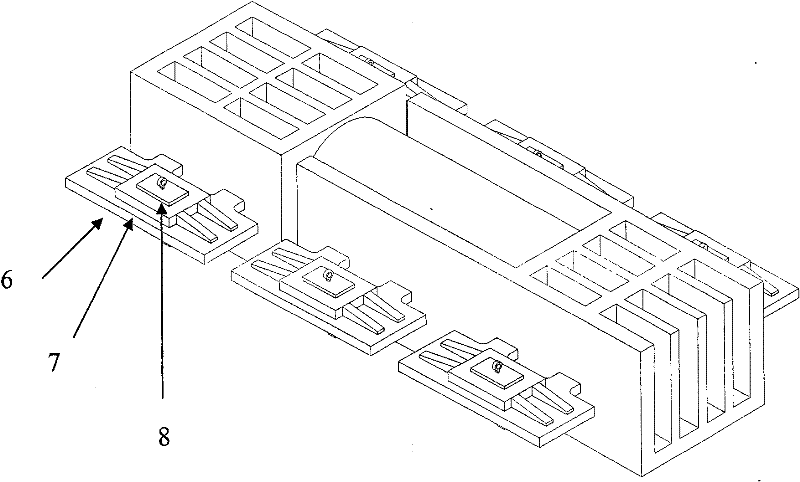

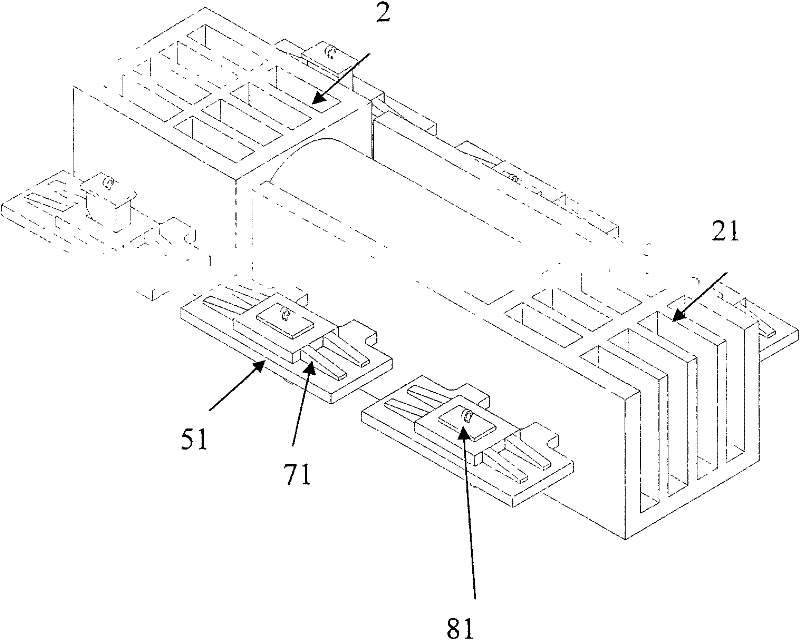

[0028] Such as Figure 1-Figure 7 As shown, the present invention includes: two hydraulic jacks 1, each hydraulic jack 1 can provide a maximum thrust of 650 tons under the drive of the hydraulic power station, and the two jacks 1 can provide a total thrust of 1300 tons. Two hydraulic jacks 1 are installed on two slideways 3 respectively, and a fixed unit 2, 21 is respectively arranged at the front and rear of the hydraulic jack 1; The fixed unit 2 arranged at the front of the hydraulic jack 1 is fixedly connected with the piston of the hydraulic jack 1 as a whole; the front of the fixed unit 2 at the front of the hydraulic jack 1 is provided with a push slider 4, and the hydraulic jack 1 is transmitted to the push slider 4, and finally the force is transmitted to the jacket. The push slide block 4 is a steel structure, and its profile is a U-shaped structure. The pushing slide block 4 concentrates the power of the two hydraulic jacks 1 and transmits them to the jacket legs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com