Radial contained squeeze-film aerostatic bearing

A gas static pressure, extrusion film technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of inability to ensure the stability and rotation accuracy of the suspension shaft, loss of balance, etc., to achieve a simple structure and improve the bearing capacity of the bearing. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

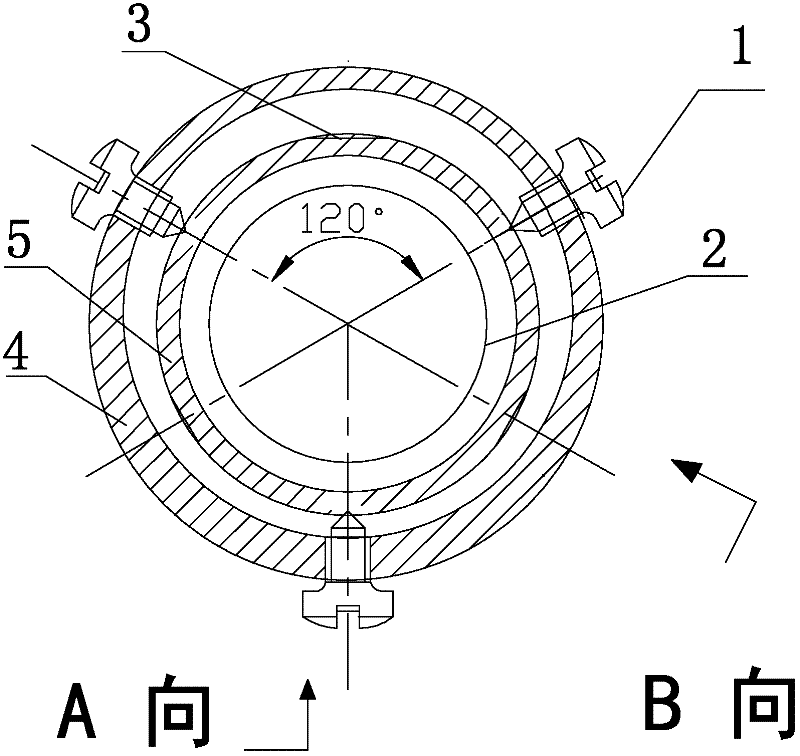

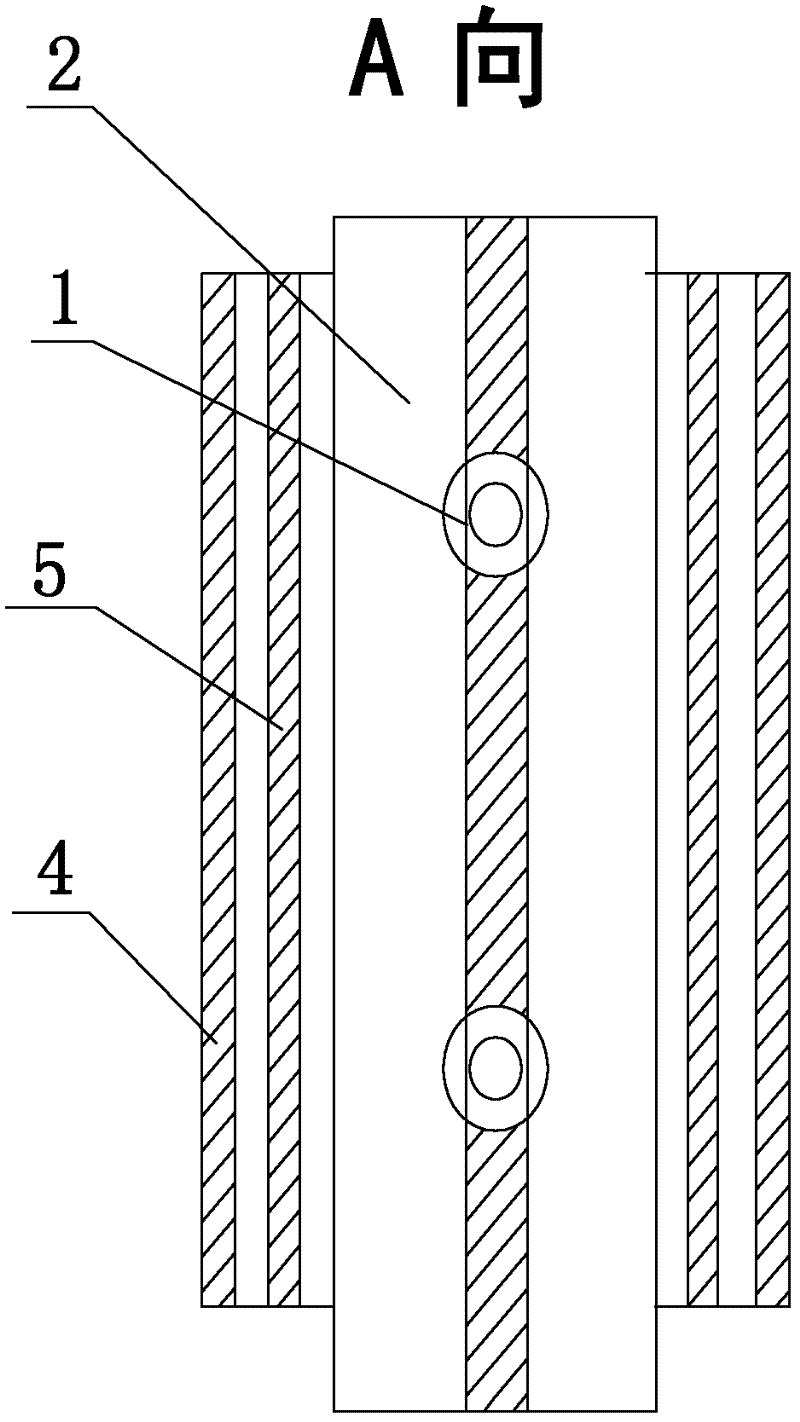

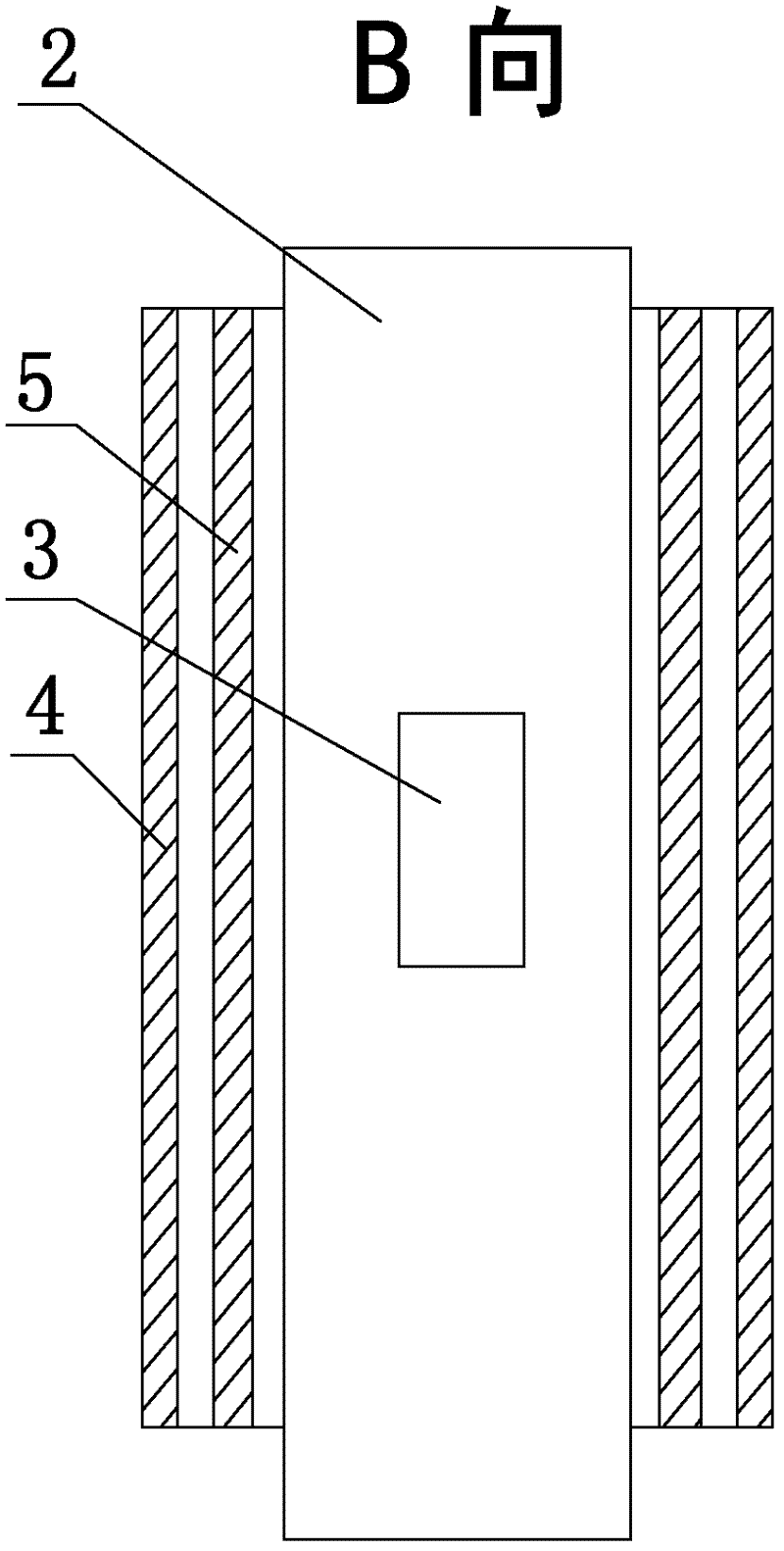

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The embodiment includes a rotating shaft 2, a piezoelectric sheet 3, an inner sleeve 5, a fastening screw 1 and an outer sleeve 4, the rotating shaft is installed in the inner sleeve, and the inner sleeve 5 and the piezoelectric sheet 3 are combined into a piezoelectric transducer , the piezoelectric transducer is composed of three groups of piezoelectric sheets 3 evenly distributed on the outer circumference of the inner sleeve, the interval between each group of piezoelectric sheets is 120 degrees, the outer sleeve 4 is set outside the inner sleeve 5, and screwed The inner sleeve is fastened to the outer sleeve. When tightening, keep the inner sleeve from deforming. Each group of piezoelectric sheets is composed of three sheets, which are pasted along the axis of the inner sleeve 5 .

[0014] When working, the three groups of piezoelectric sheets (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com