High-speed neutron photographing device

A camera device, neutron technology, applied in high-speed photography, focusing device, photography, etc., can solve the problem of difficult to meet the field of view range and resolution requirements, and achieve automatic adjustment measurement, ideal shielding effect, and simplify the shielding structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

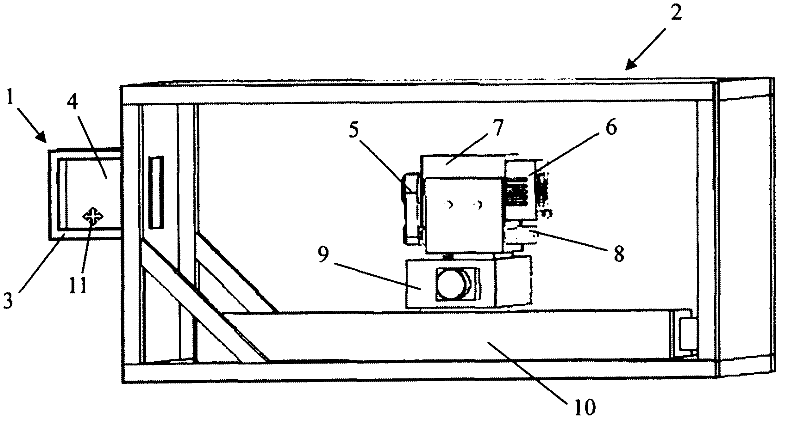

[0017] Such as figure 1 As shown, the high-speed neutron imaging device includes two parts: a neutron conversion cavity 1 and a detection cavity 2 . The neutron conversion cavity 1 converts neutron images into visible light images, and the detection cavity 2 is used to collect light signals. The frame material of the two cavities is made of aluminum alloy profiles with a cross-section of 2cm*2cm, and the outer skin is clad with 2mm thick aluminum foil. The cavities are connected by 4 screws. In this embodiment, the frame volume of the neutron conversion cavity is 40cm*40cm*40cm, and the frame volume of the detection cavity is 60cm*80cm*120cm.

[0018] The neutron conversion chamber 1 is provided with a scintillation screen 3 for converting neutron images into visible light images, and a plane mirror 4 is provided behind the scintillation screen 3 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com