Method for eliminating damage of hot marks by controlling operating point with set voltage range of photovoltaic module

A photovoltaic module, control and elimination technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as large heat, achieve the effects of reducing power loss, reducing safety hazards, and eliminating hot spot damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

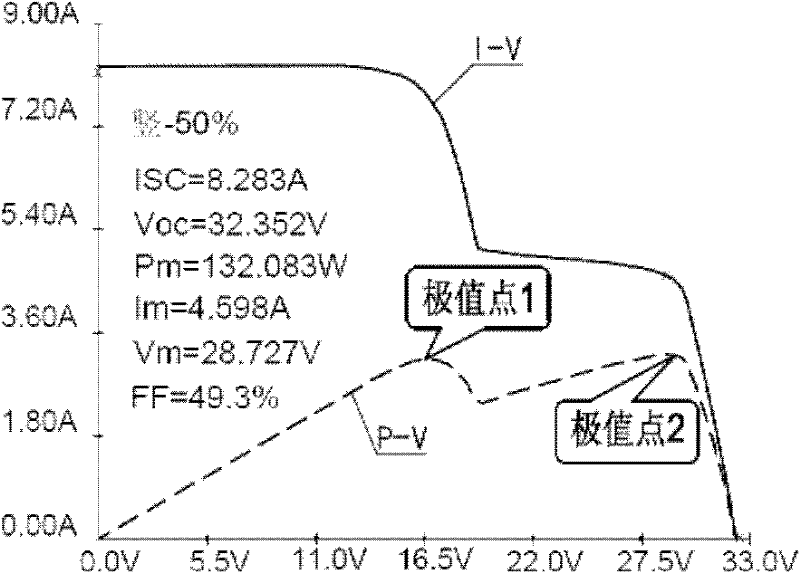

[0011] figure 1 It is the IV and PV curve diagram of the photovoltaic module under the condition of mismatch, and the PV (power and voltage) curve is at the low voltage ( figure 1 middle extreme point 1) and high voltage ( figure 1 The middle extreme point 2) each has a power maximum value. With or without the bypass diode, when working near the extreme point 1, the operating point voltage V1 is low, and most of the voltage (Voc-V1) generated by the component gathers at both ends of the shaded battery, and there is a current I1 (compared to Large, close to short-circuit current) passes through, so that the shaded battery generates a lot of heat, and the hot spot effect appears; when it is near the extreme point 2, the operating point voltage is high, and the power lost by the solar battery module is more evenly distributed among the unshaded batteries of the module Above all, the voltage at both ends of each battery in the module is not high, the passing current is not large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com