Capsule for preparing a beverage by centrifugation in a beverage preparation device and device adapted therefore

A technology of centrifugation and beverage preparation, applied in the direction of beverage preparation devices, applications, household appliances, etc., to achieve the effect of increased interaction time and improved beverage output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

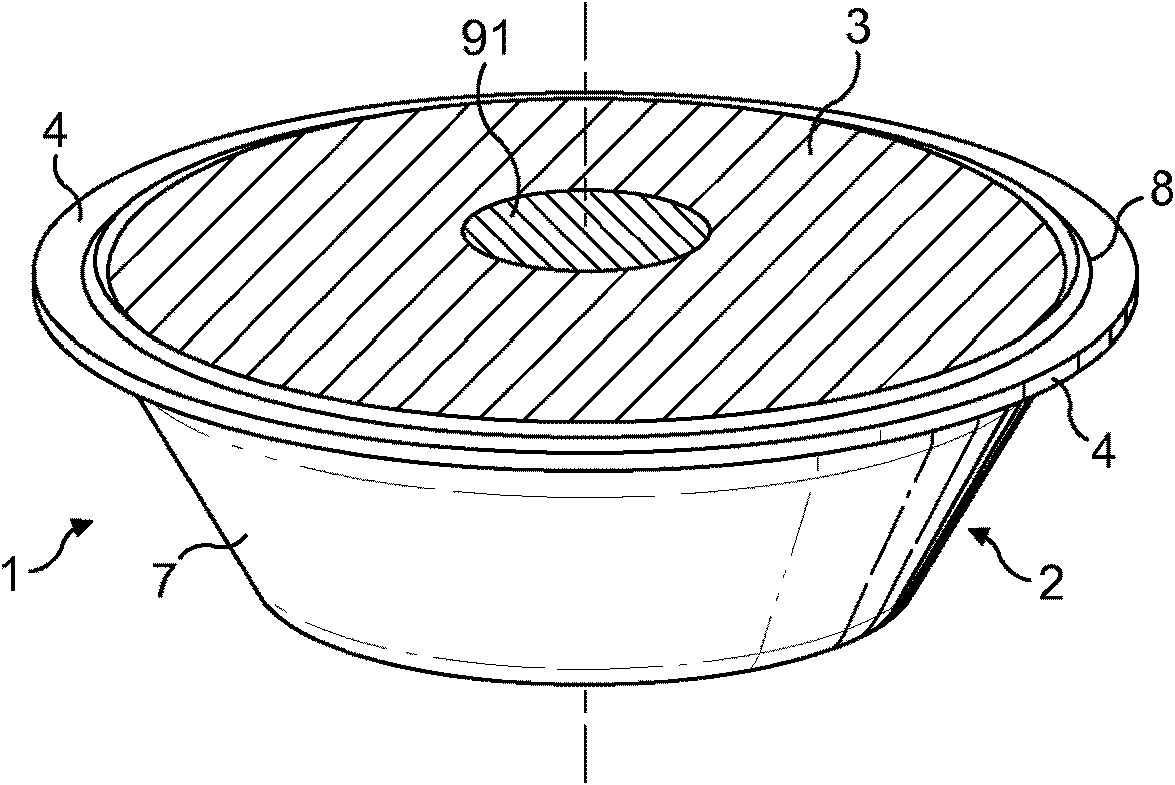

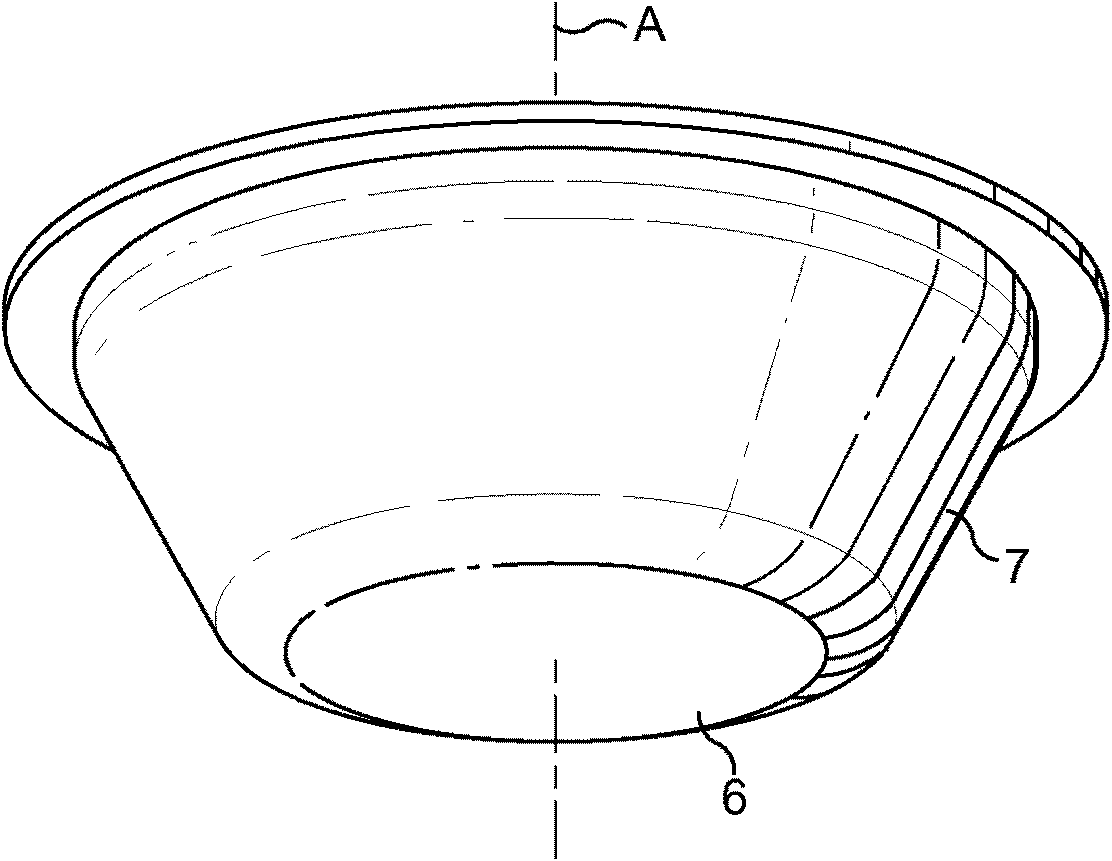

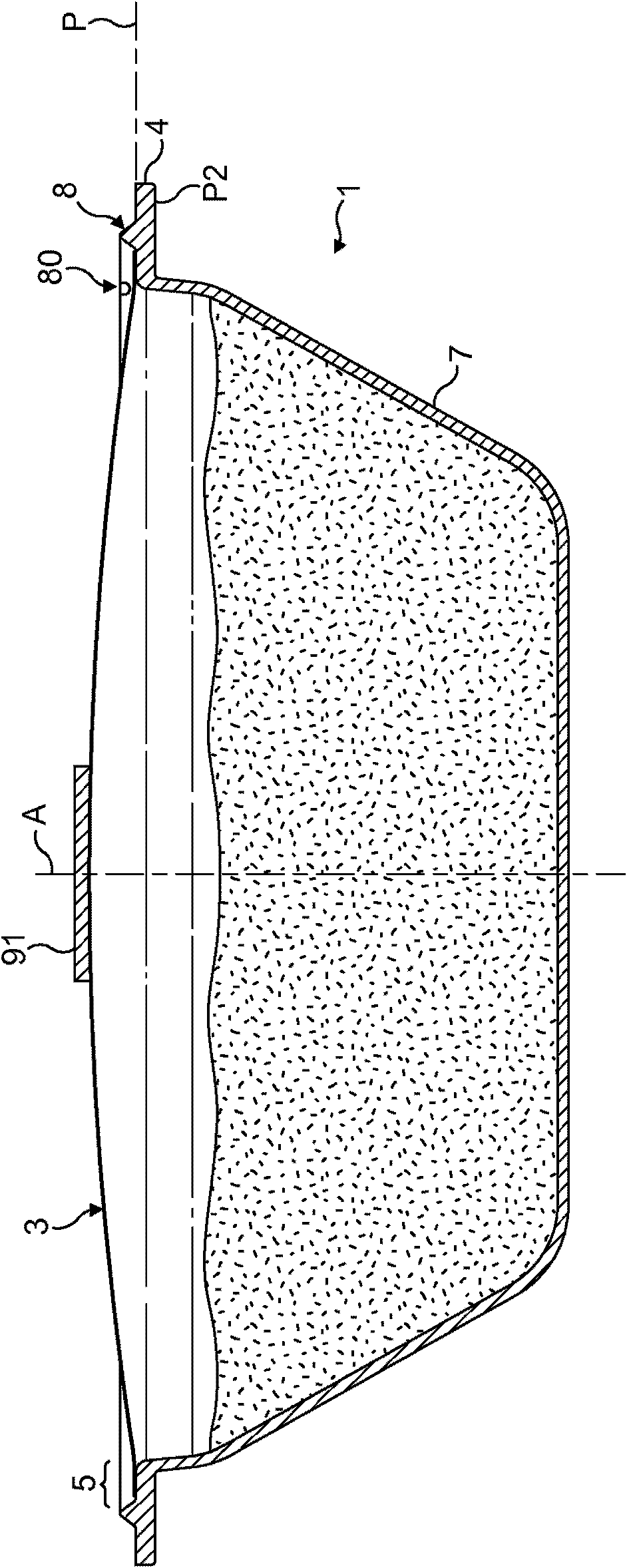

[0078] Such as figure 1 with figure 2 As shown, the preferred disposable capsule 1 of the present invention generally includes a concave disc-shaped body 2 on which a perforated membrane 3 is sealed. The membrane 3 is sealed to the peripheral edge 4 of the body at the annular sealing portion 5 on the inside. The edge 4 may extend outward to form a small annular sealing portion 5 of about 2-10 mm. The concave disc-shaped body includes a bottom wall 6 and a side wall 7, and the side wall 7 preferably widens toward the large open end of the body opposite to the bottom wall. The concave disc-shaped body is preferably rigid or semi-rigid. It can be made of food grade plastics (such as polypropylene) or aluminum alloys or plastic and aluminum alloys with a gas barrier layer (such as EVOH, etc.) or biodegradable materials (such as PLA or starch and fiber-based synthetic resins) production. The film 3 may be made of a thinner material such as a plastic film layer that also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com