Shifting assembly for shifting the reverse gear of a variable speed gearwheel transmission and variable speed gearwheel transmission

一种齿轮变速器、变速器的技术,应用在离合器、机械驱动离合器、机械设备等方向,能够解决长换档时间、过多结构空间、高制造成本等问题,达到小结构空间、少结构空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

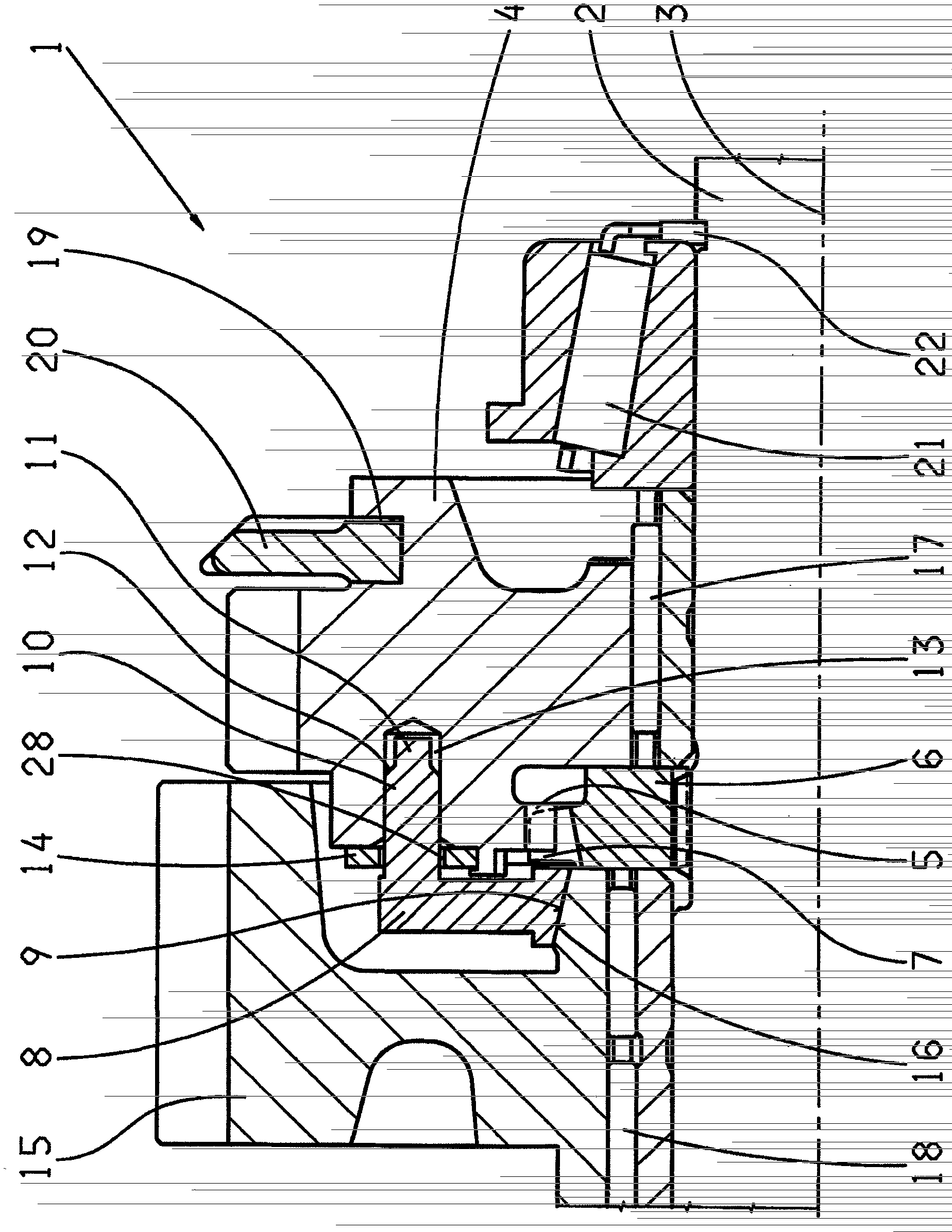

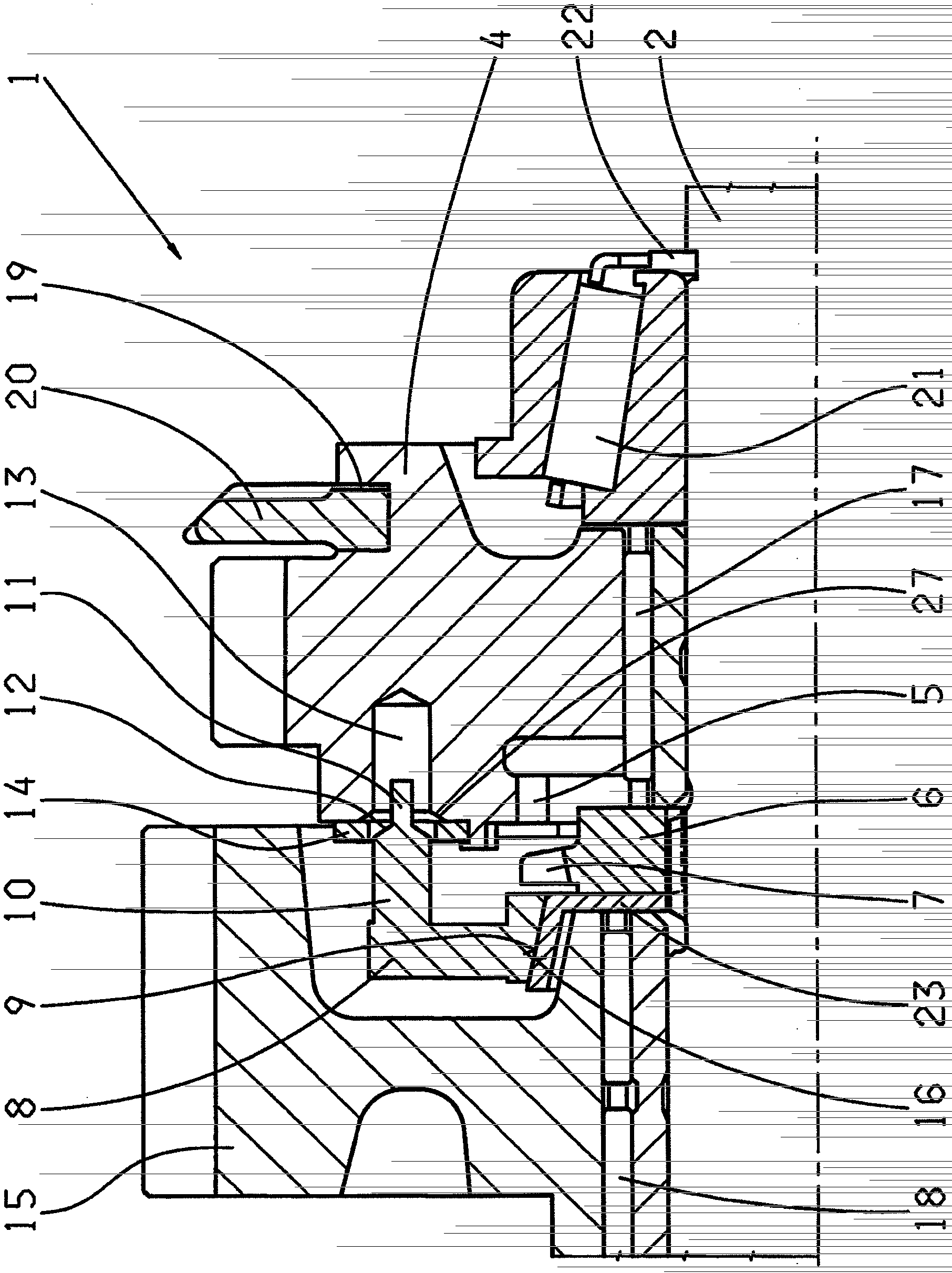

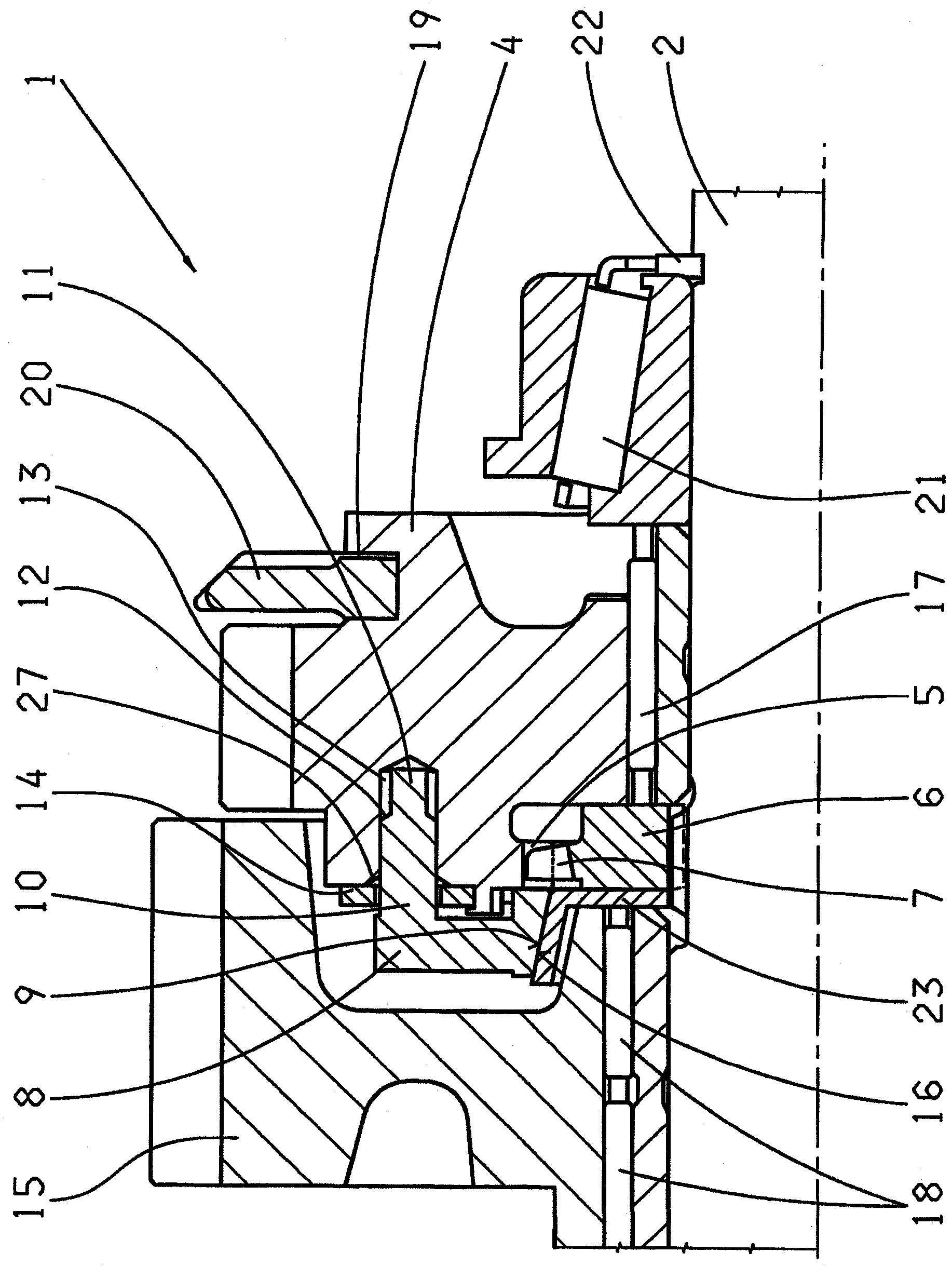

[0030] In the shifting system 1 according to the present invention figure 1 In the embodiment shown in , the reverse gear 4 is arranged rotatably and axially displaceably on the transmission shaft 2 . The reverse gear rotates about the central axis 3 of the transmission shaft 2 and is supported on the transmission shaft 2 by means of rolling bearings 17 . In the region of the outer circumference of the reverse gear 4 , the reverse gear 4 has a groove 19 into which the end of the shift fork 20 engages. In addition to the reverse gear 4 , a forward gear 15 is also mounted rotatably about the center axis 3 on the transmission shaft 2 via rolling bearings 18 .

[0031] On the side of the reverse gear 4 facing away from the forward gear 15 , a roller bearing 21 is arranged on the transmission shaft 2 , via which roller bearing 21 the transmission shaft 2 is supported in a transmission housing (not shown). The transmission shaft 2 can be, for example, the output shaft of the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com