Mechanical seedling feeding transplanter

A transplanting machine and mechanical technology, applied in the direction of transplanting machinery, application, agriculture, etc., can solve the problems of poor economic benefits that have not been popularized and applied, unsuitable seedling cultivation methods in plug trays, and low machine transplanting efficiency, etc., to achieve the goal of transplanting Fast speed, infrequent action, saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below.

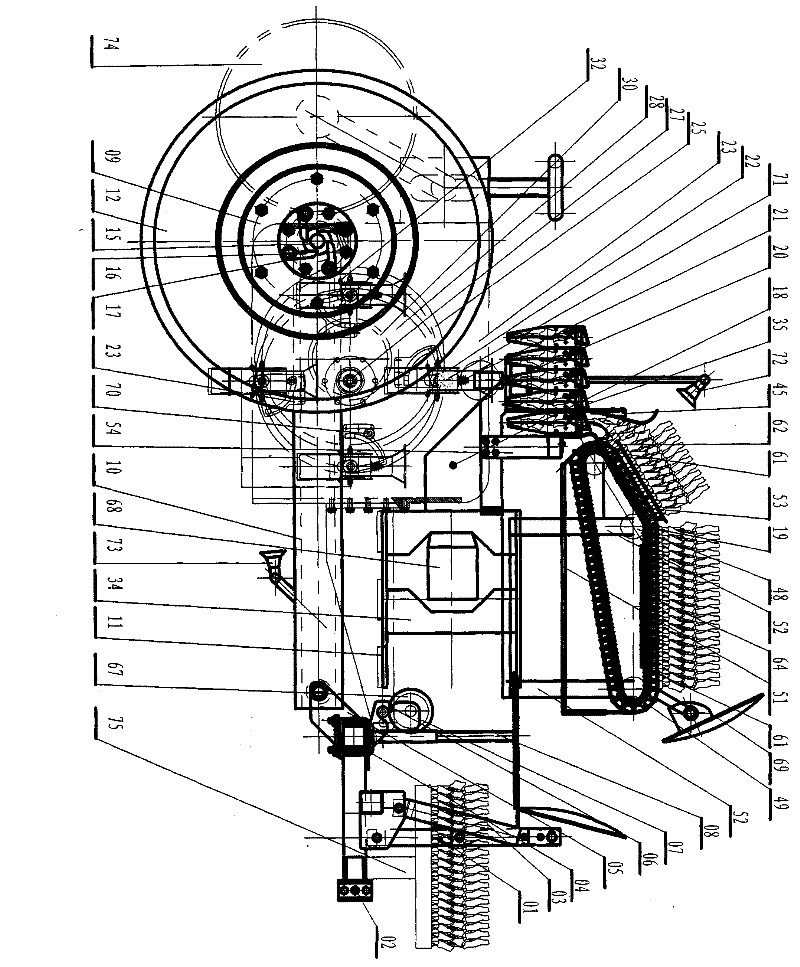

[0023] The system consists of frame device assembly, ground wheel device assembly, inserter assembly, semi-automatic seedling throwing device assembly, support assembly, baffle assembly, transmission device assembly, electrical system assembly, and soil covering suppression device assembly , seedling racks and other components.

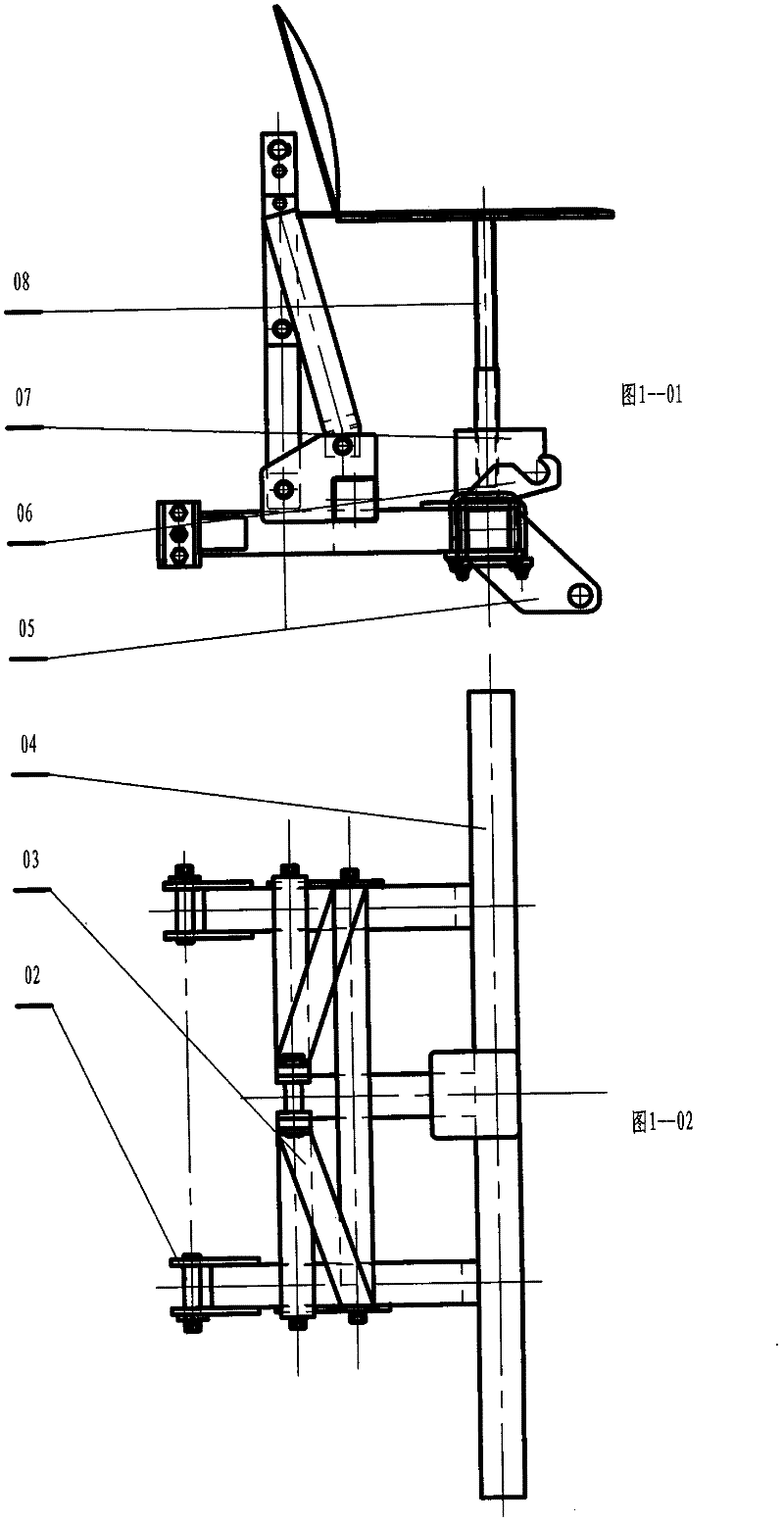

[0024] 1. 1-rack device assembly includes:

[0025] 2-connection pin, 3-connection bracket assembly A, 4-fixed beam, 5-transplanting device connection plate, 6-transmission shaft connection plate, 7-transmission device connection plate, 8-passenger seat and other components.

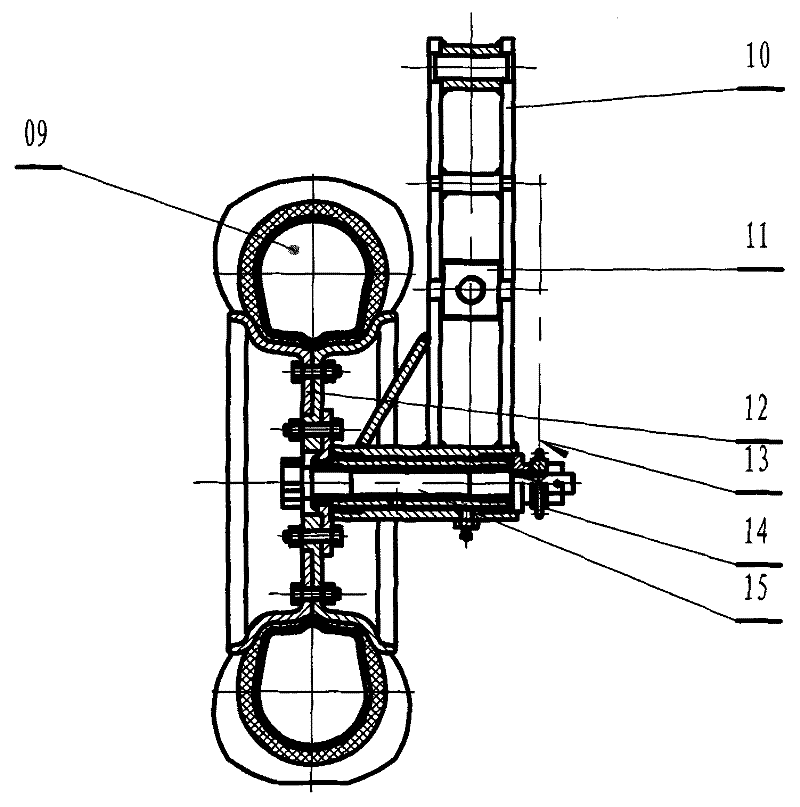

[0026] 2. 9-Ground wheel device assembly includes:

[0027] 10-connecting bracket assembly B, 11-rocking plate, 12-ground wheel assembly, 13-chain A, 14-sprocket A, 15-transmission shaft A, 16-ratchet, 17-spring and other components.

[0028] The working principle is: when the 12-ground wheel assembly is pulled forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com