Full-automatic green Chinese onion transplanter

A transplanting machine, fully automatic technology, applied in the field of transplanting machines, can solve the problems of slowing down the transplanting speed of seedlings, slowing down, and stuttering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

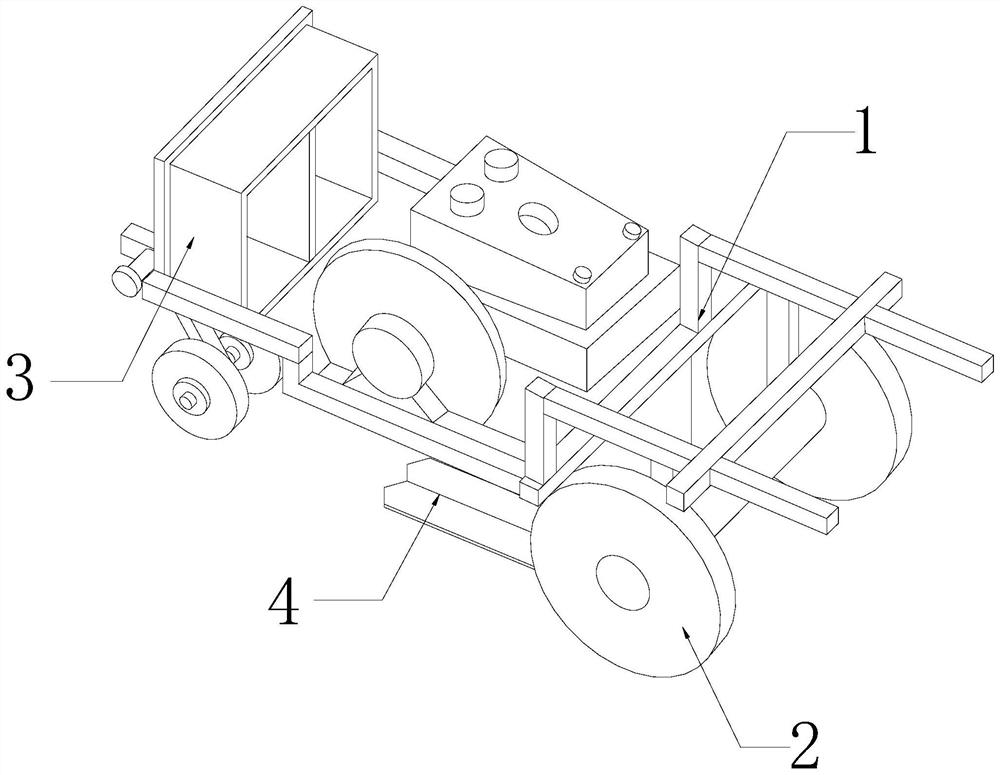

[0029] as attached figure 1 To attach Figure 6 Shown:

[0030] The present invention provides a fully automatic scallion transplanting machine, the structure of which includes a body 1, support wheels 2, a placement frame 3, and a conveying device 4. The bottom surface is fixed at the upper surface position in front of the body 1, and the top of the conveying device 4 is connected with the bottom surface position near the rear of the body 1.

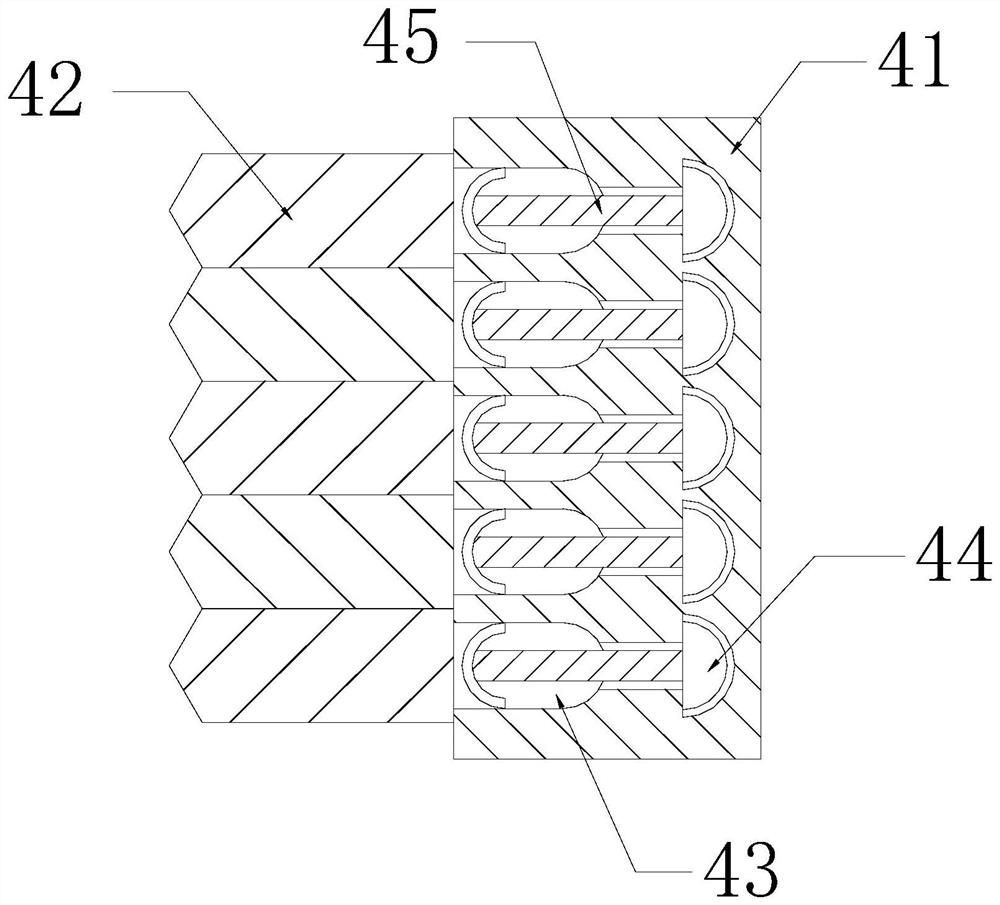

[0031] Described conveying device 4 comprises support block 41, seedling board 42, sliding chamber 43, controller 44, delivery rod 45, and described seedling board 42 right end is fixed on the left side position of supporting block 41, and described sliding chamber 43 is opened on the support Between the left side of the block 41 and the inside, the controller 44 is placed inside the right end of the sliding chamber 43, and the right end of the delivery rod 45 is movably matched with the left side of the controller 44.

[0032] Where...

Embodiment 2

[0039] as attached Figure 7 To attach Figure 9 Shown:

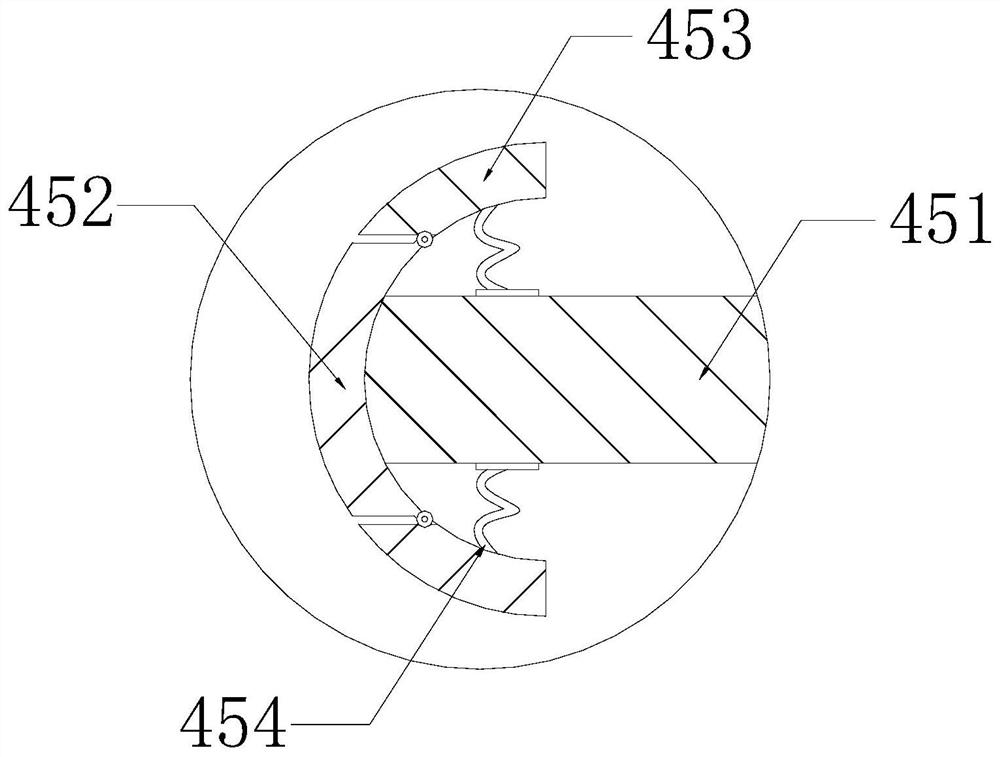

[0040] Wherein, the push plate 452 includes a support plate 52a, a connection block 52b, a bottom plate 52c, and a telescopic rod 52d, the top of the connection block 52b is fixed on the bottom surface of the support plate 52a, and the upper surface of the bottom plate 52c is installed on the bottom end of the connection block 52b. The upper and lower ends of the telescopic rod 52d are respectively connected to the inner wall positions near the two ends of the support plate 52a and the bottom plate 52c. The connecting block 52b is provided with three, which can increase the driving force of the connecting block 52b to the bottom plate 52c, which is beneficial to the bottom plate 52c. At the inner bottom of the sliding chamber 43, two telescopic rods 52d are provided, which are symmetrically distributed and can expand with the movement of the bottom plate 52c. During this period, the moving speed of the bottom plate 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com