Ultrasonic emulsifying method and equipment for replacing role of clouding agent

A technology of ultrasonic wave and clouding agent is applied in the field of ultrasonic emulsification method and processing equipment for realizing the method, which can solve problems such as chronic diseases and metabolic disorders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

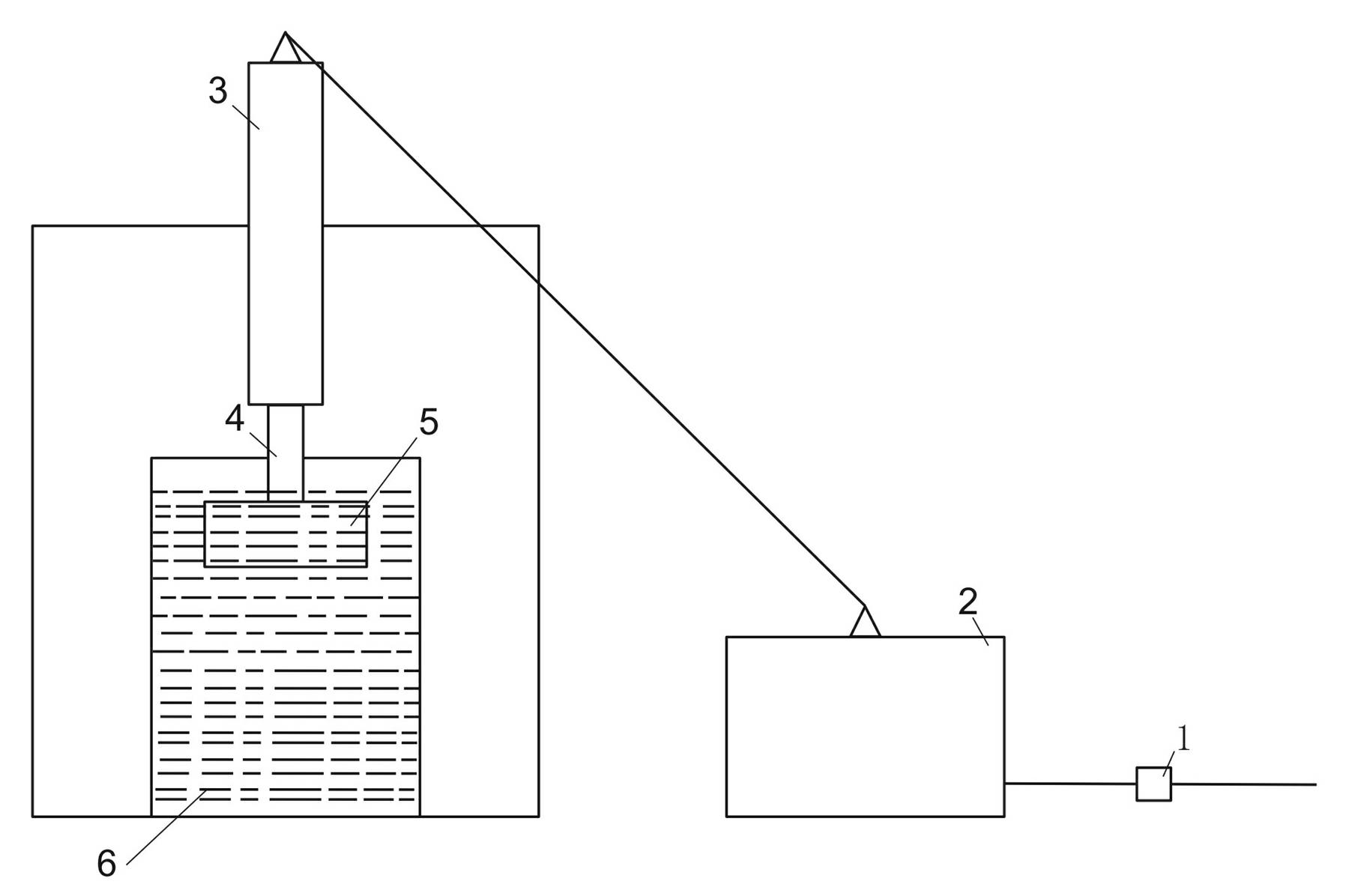

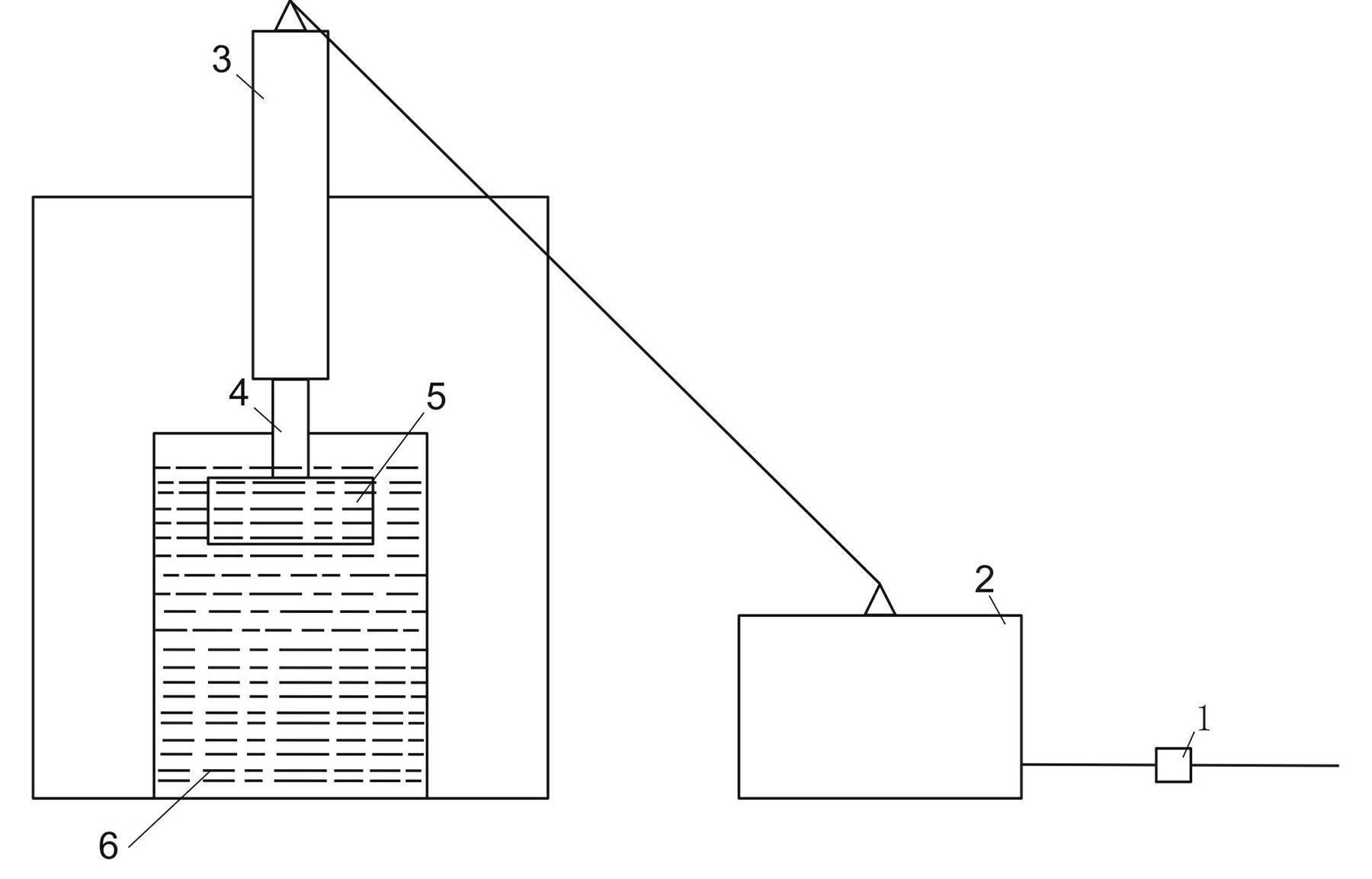

[0015] Embodiment: A kind of ultrasonic emulsification equipment used for filling beverages, using an ultrasonic vibration source to convert the 50Hz electric energy of the civil power supply of the power supply bureau into a high-frequency 100kHz power supply 1 through a power converter 2, and provide it to the ultrasonic transducer element 3; The transducer element 3 converts high-frequency electric energy into mechanical vibration energy, and connects the transducer element 3 and the emitter 5 through the connection element 4, and transmits the mechanical vibration energy of the transducer element to the emitter 5, and finally the emitter 5 Send ultrasonic energy into the liquid (250 ml) mixed with oil (or essence, sesame oil, etc.) and water (1:50) 6, after 60-120 seconds (if the volume of the liquid increases, the time should be extended appropriately) ultrasonic emulsification , so that the droplet size of the emulsified product made of liquid is less than 0.2 μm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com