Turbulent-flow crushing machine of soybean milk maker

The technology of a pulverizing device and a soymilk machine is applied to beverage preparation devices, milk substitutes, household appliances, etc., which can solve the problems of prolonged pulverization time, shutdown of the soymilk machine, poor defoaming effect, etc., so as to reduce the pulverization time and improve the defoaming effect. , the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

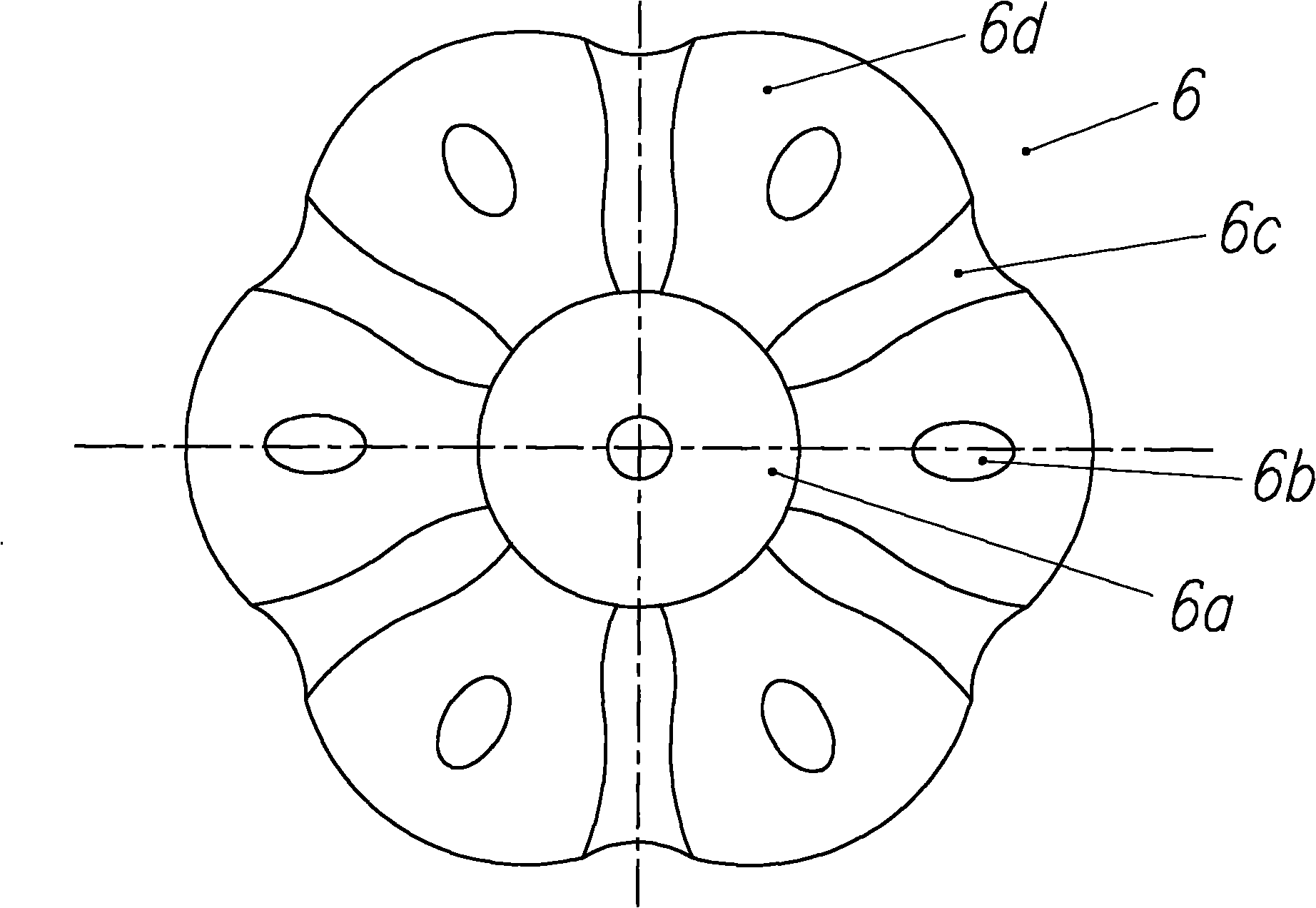

[0026] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the bottom surface of the spoiler 6 is provided with regularly distributed concave units 6e. The concave unit 6e arranged on the bottom surface can also play a role in enhancing the effect of turbulence.

Embodiment 3

[0028] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the spoiler assembly is a spoiler-shaped body composed of a plurality of spoilers 6f welded or fixedly connected to a mounting plate 6a. Also on each spoiler 6f are respectively provided with protruding unit 6d, this kind of spoiler-shaped body composed of spoiler 6f, because there is a gap between adjacent spoilers, this gap plays a role in spoiling the flow. The role of the hole, so the spoiler 6f does not need to be specially provided with a spoiler hole.

[0029] At the same time, in all the above-mentioned embodiments, the spoiler assembly is directly connected to the lower cover 4 of the machine head, but it can also be indirectly connected to the lower cover 4 of the machine head through an intermediate component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com