Method for eliminating macro C segregation by performing heat preservation on continuously cast steel billets

A billet and continuous casting technology, applied in the field of metallurgy, can solve problems such as insignificant effect, inability to produce segregation-free billets, and inability to solve problems completely, achieving the effects of simple operation, increased diffusion and homogenization efficiency, and easy access to equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

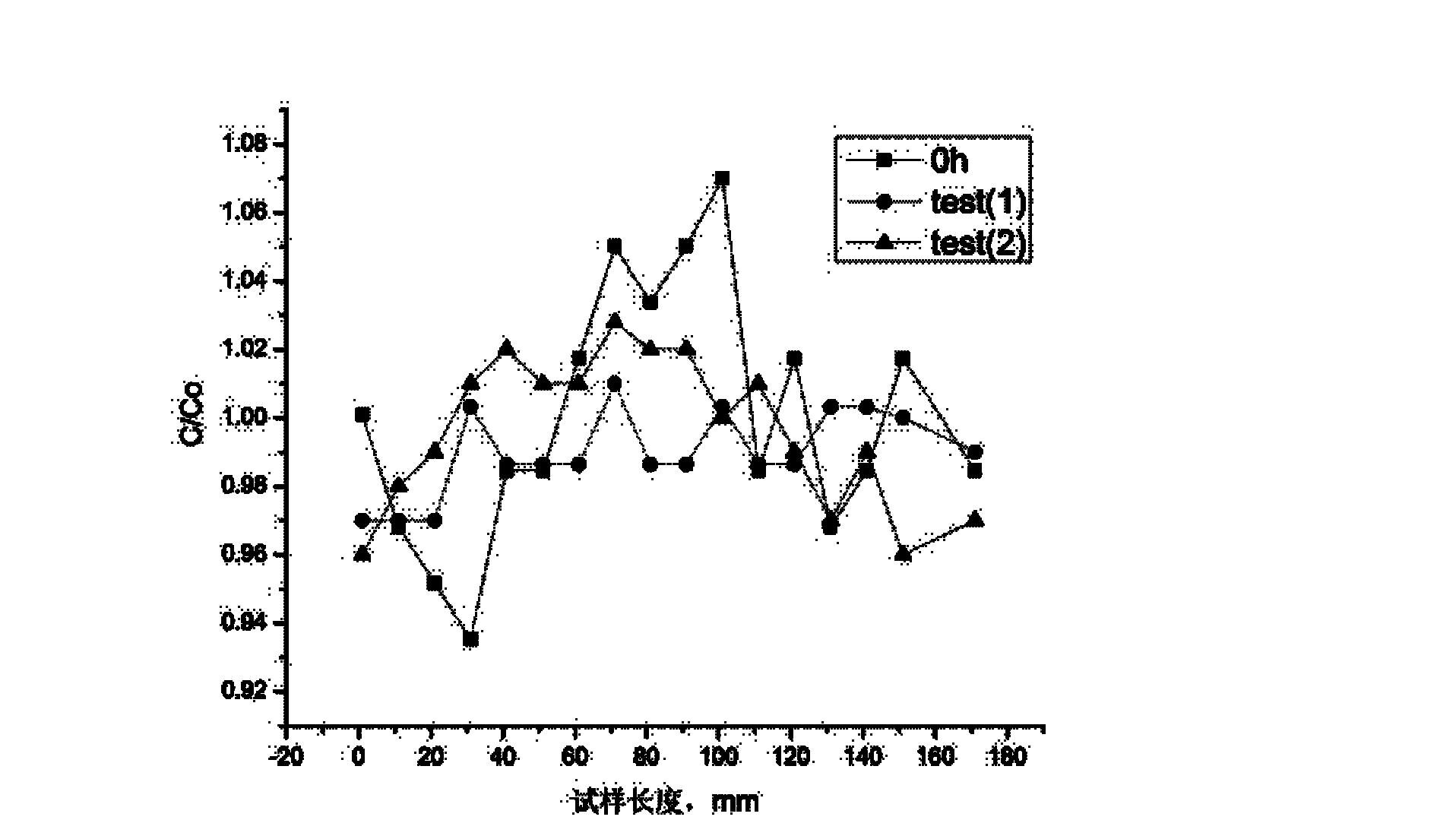

[0019] The purpose of the present invention is to propose a method for continuously casting steel slabs to keep warm to eliminate macroscopic C segregation, which can effectively increase the diffusion and homogenization efficiency of C to eliminate macroscopic C segregation. This method only needs to determine the T of the specific steel type 1 and T 2 , the effective control of the macro-segregation of the continuous casting billet can be realized.

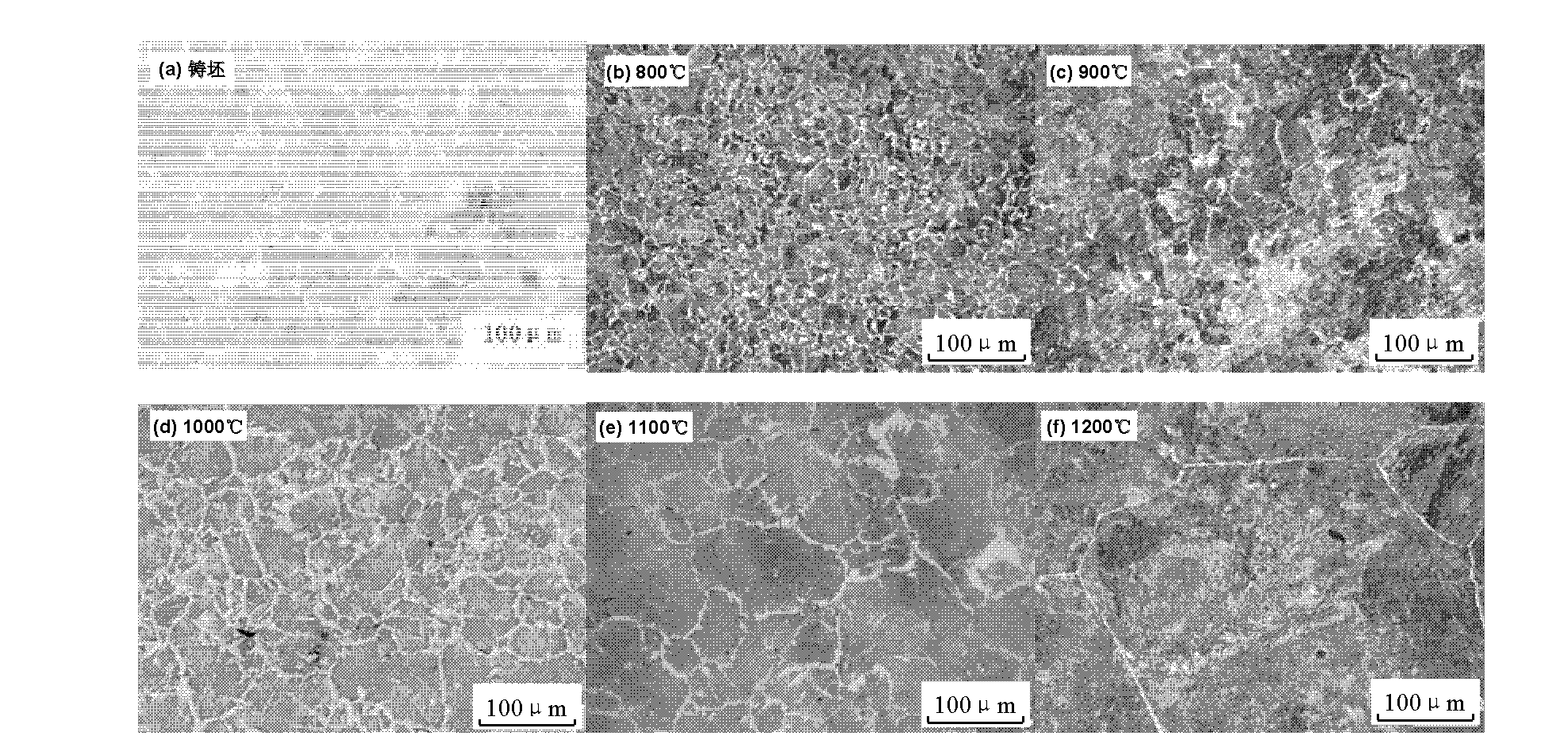

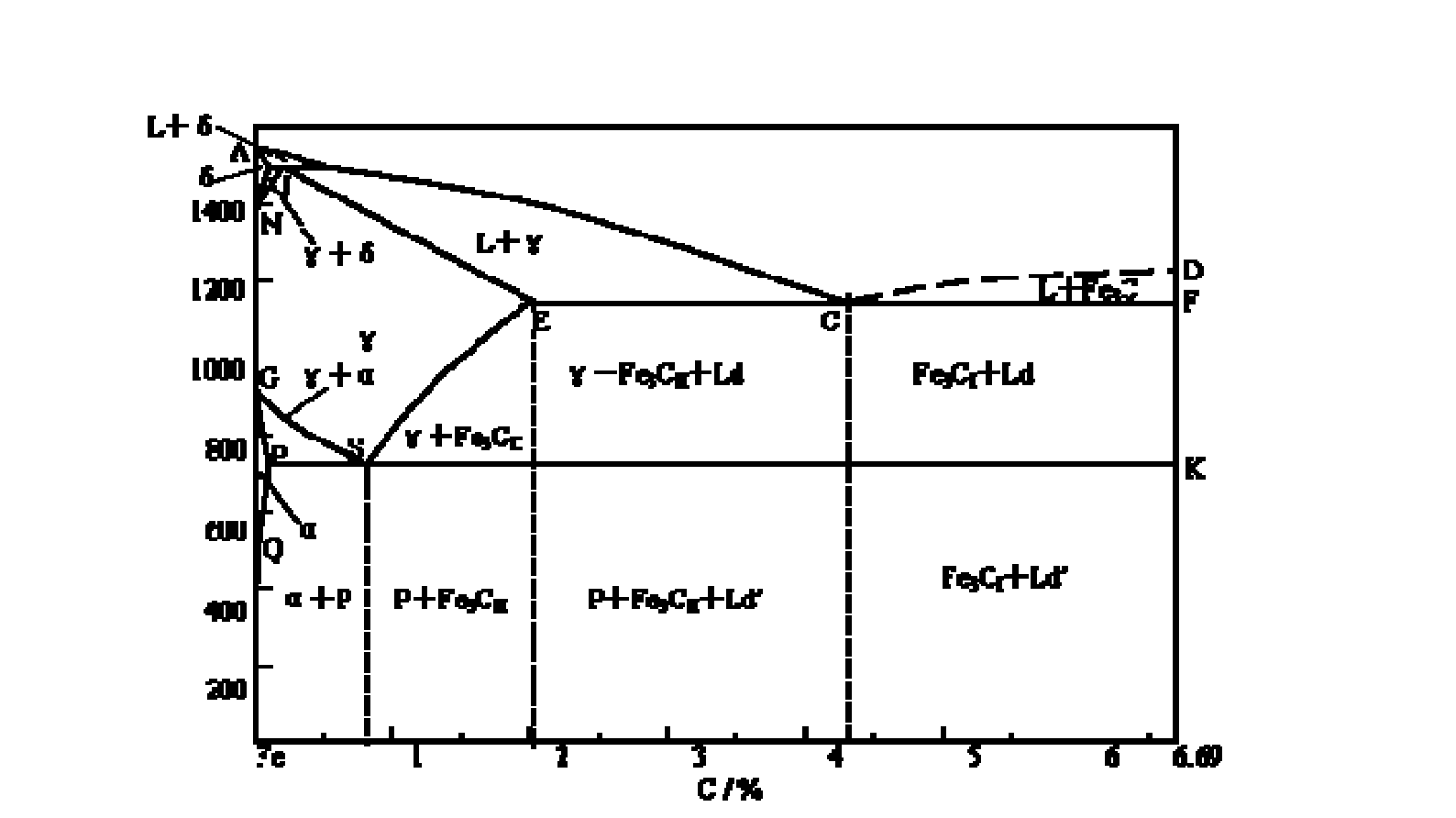

[0020] Take CL60 wheel steel as an example. Step 1, according to the diffusion coefficient Arrhenius formula (1), it can be known that the higher the temperature, the greater the diffusion coefficient of elements; however, for general steel grades, too coarse grain structure will seriously affect the subsequent processing performance and product quality. Therefore, the standard for the heat preservation temperature in this experiment is the highest temperature at which the grains do not grow abnormally after long time heat pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com