Special fixture for milling long and thin axle parts

A special fixture and slender shaft technology, applied in the direction of metal processing machinery parts, clamping, manufacturing tools, etc., can solve the problem of inability to guarantee the machining accuracy of parts, and achieve the effect of slowing down machining deformation, improving productivity and improving machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

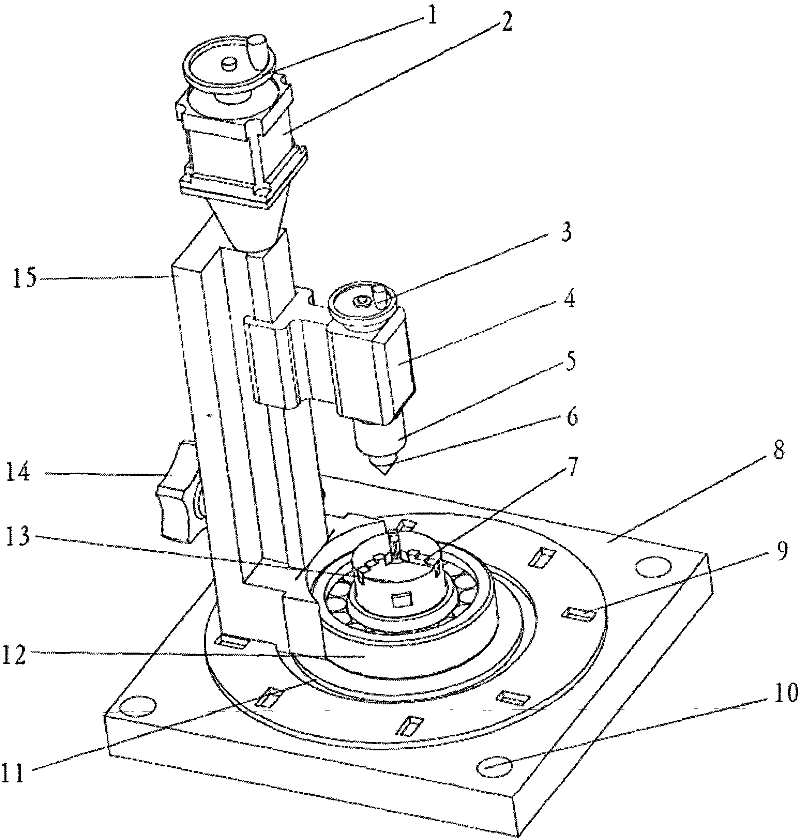

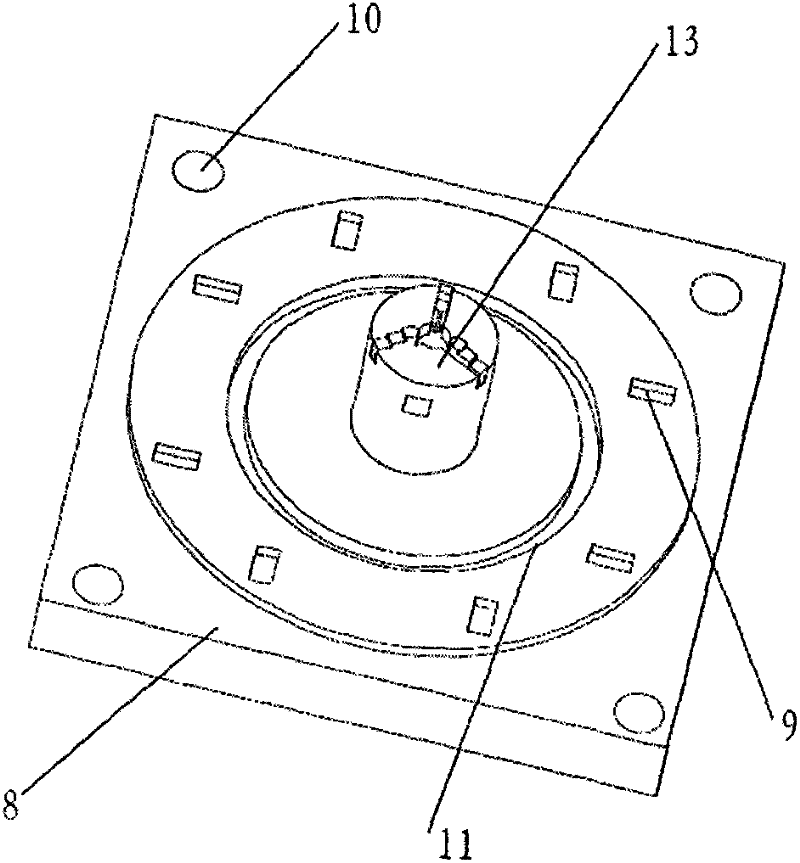

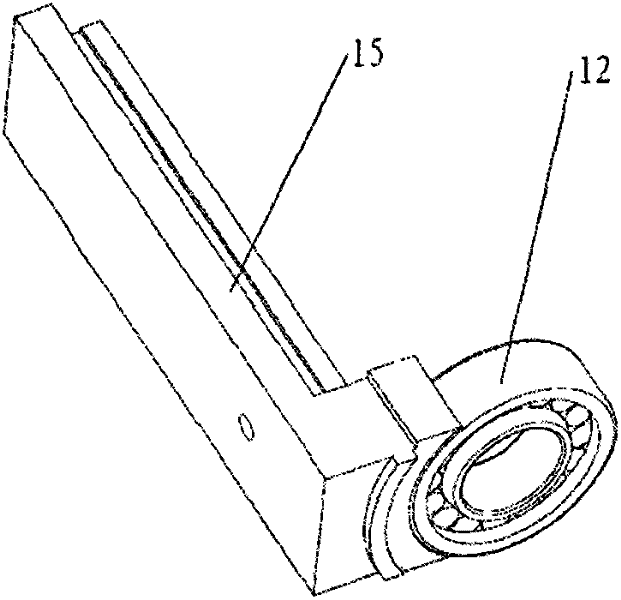

[0012] Such as Figure 1 ~ Figure 3 The shown special fixture for milling machine of slender shaft parts has positioning grooves 9 on the fixture base 8, and the positioning grooves 9 are equiangularly distributed on the fixture base 8 around the axis of the shaft 12, and the diameter of the circular chute 11 is equal to 6 / 5 to 7 / 5 of the bearing diameter is used to support the support arm 15, and the bolt hole 10 is used to insert bolts to fix the fixture, wherein the three-jaw chuck 13 is fixedly connected to the upper surface of the fixture base 8, and the three-jaw chuck 13 It is fixedly connected with the inner ring of the bearing 12, and the outer ring of the bearing 12 is fixedly connected with the support arm 15. The support arm 15 can rotate around the bearing 12, and a circular chute with the three-jaw chuck as the center on the upper surface of the fixture base 8 11 sliding support, the support arm 15 has a handle 14, a handle box 2, a handwheel handle 1 and a tails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com