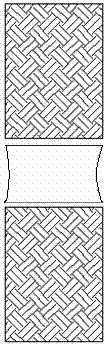

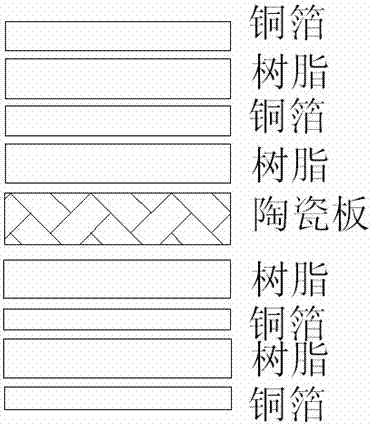

Liquid pore-filling vacuum stitching process

A vacuum lamination and liquid technology, applied in lamination, lamination devices, lamination auxiliary operations, etc., can solve the problems of easy separation, displacement of conductive points, high cost, etc., and save grinding equipment and grinding materials , increase the space for expansion and contraction, and save power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Immerse the ceramic plate in the pickling solution for pickling, heating to 33~37℃, pickling time of 16~20 seconds, pickling pressure of 0.3~1.3kg / cm2 to wash away the oxides on the surface of the copper layer, and then use Rinse the ceramic plate with running water for 20-25 seconds. The pickling solution is prepared with a ratio of 10-20g copper, 15-50ml 98% concentrated sulfuric acid and 1L water;

[0037] 2) Heat the alkaline degreaser (main component is sodium hydroxide) with a concentration of 80~120ml / L to 48~52℃, and immerse the ceramic plate in the degreaser for 30~35 seconds, the pressure is 0.3~1.3kg / cm2 , To remove oil stains on the surface of the copper layer, wash with deionized water for 20-25 seconds at room temperature, and the washing pressure is 0.5-1.5kg / cm2;

[0038] 3) Immerse the ceramic plate into the activation solution. The temperature of the activation solution is 38~42℃, the pH value is 5~8, and the activation time is 18~20 seconds. The copper ...

Embodiment 2

[0048] 1) Immerse the ceramic plate in the pickling solution for pickling, heating to 33~37℃, pickling time of 16~20 seconds, pickling pressure of 0.3~1.3kg / cm2 to wash away the oxides on the surface of the copper layer, and then use Rinse the ceramic plate with running water for 20-25 seconds. The pickling solution is prepared with a ratio of 10-20g copper, 15-50ml 98% concentrated sulfuric acid and 1L water;

[0049] 2) Heat the alkaline degreaser (main component is sodium hydroxide) with a concentration of 80~120ml / L to 48~52℃, and immerse the ceramic plate in the degreaser for 30~35 seconds, the pressure is 0.3~1.3kg / cm2 , To remove oil stains on the surface of the copper layer, wash with deionized water for 20-25 seconds at room temperature, and the washing pressure is 0.5-1.5kg / cm2;

[0050] 3) Immerse the ceramic plate into the activation solution. The temperature of the activation solution is 38~42℃, the pH value is 5~8, and the activation time is 18~20 seconds. The copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com